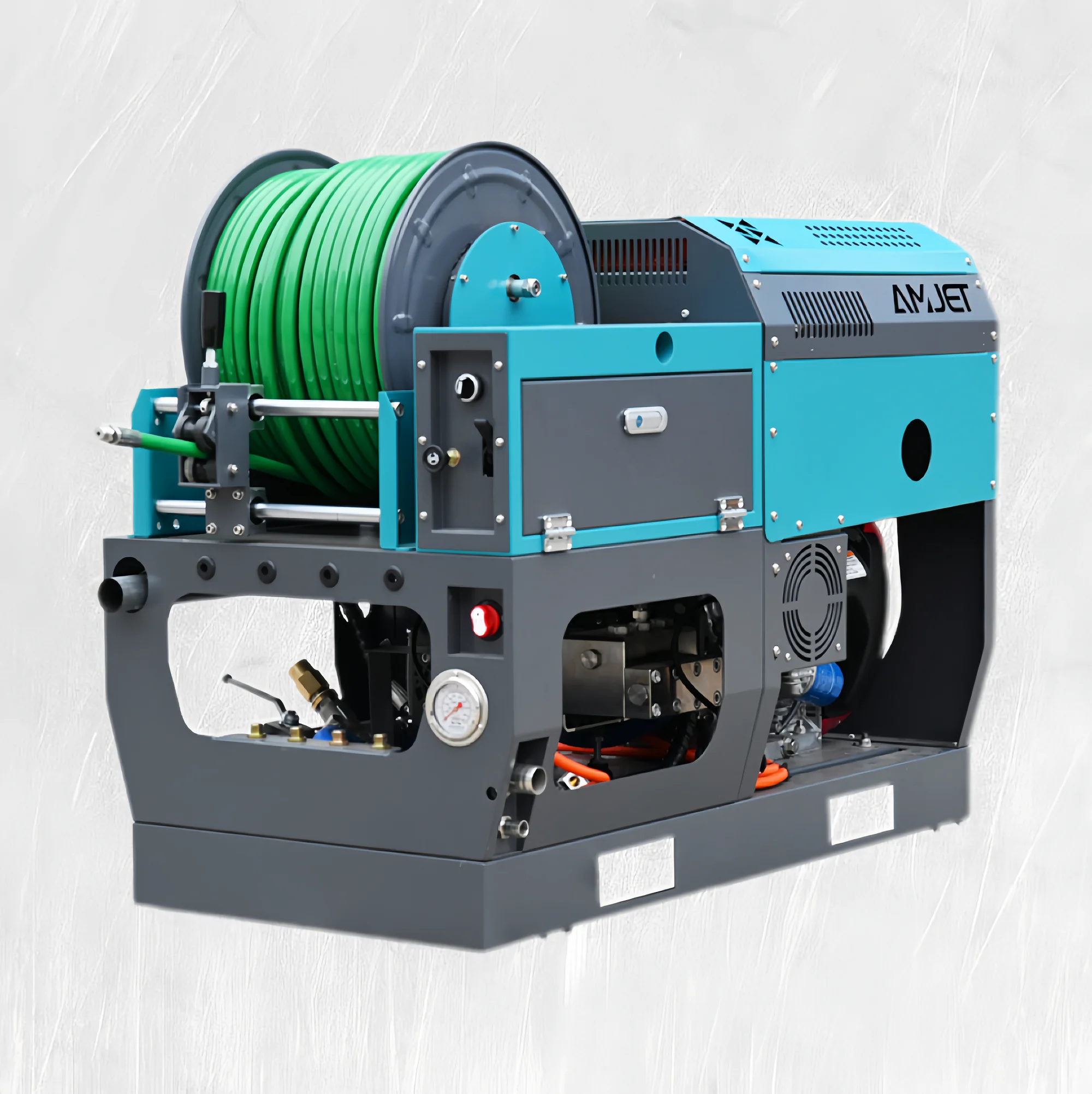

Waterblasting pump unit PW 303 DD diesel engine washing equipment 2800bar

- Category: >>>

- Supplier: Power (Tianjin) Technology Limited Company

Share on (1601042460834):

Product Overview

Description

Application:

Ship hull surface preparation

Painting removal

Rust removal

Water tank/Oil tank deposits removal

Industrial high pressure cleaning

Water blasting

Hydro jetting

Pressure testing

Industrial tube/pipe cleaning,etc

Product parameters:

PW-303-DD

Power PW-303-DD ultra-high-pressure diesel pump unit is the most advanced and efficient water blasting pump in the industry. It is powered by the diesel engine of 221kw-265kw(300HP-360HP). Optional Cummins, Weichai, Caterpillar diesel engine as the client's request.

| Diesel engine powewr | 300-360HP |

| Output pressure | 18-280Mpa |

| Output flow | 30-635L/min |

| Dimensions | LxWxH=4000x1800x2400(mm) |

| Equipment weight | 4800Kg |

| Model | Pressure | Flow rate | Plunger diameter(mm) |

| PW-303-46.4K | 46400psi(3200bar) | 38Lpm(10.032Gpm) | 20 |

| PW-303-43.5K | 43500psi(3000bar) | 45Lpm(11.88Gpm) | 22 |

| PW-303-40K | 40000psi(2800bar) | 54Lpm(14.256Gpm) | 24 |

Advantages:

1.Durable: the latest design makes the compact structure, the reducer ratio 4.96:1 makes the low speed 405 rpm of pump. So that the service life is longer than the old type of pump.

2. Reliable: The twin helical gear transmission which horizontally oposed helical gears to eliminate the axilal stress makes the low noise, high efficiency and more reliable. The liquid end is seperated with the power end, the plunger and liner can be changed in 5 minuts. so the pump units can run continously. The rotating speed of pump can be reduced to 405rpm with the helical gears box, the low rpm means the long service life under the high pressure.

The whole machine has lightweight design, modulay layout, and the overall structure is reasonable and compact. Two kinds of lifting holes are convenient for lifting different lifting equipment on site. Advanced engine, the mechanical power unit, combined with the self-developed electric operation system, with multiple signal sources to collect data, realizes the ATC function of the engien and the high-pressure piston pump. This proves the safety of operation and fuel economy. The vertical pump set structure eliminates the wear of the plunger seal structure caused by gravity and improves the service life. Non-filled, the high-pressure sealing structure of the material reduces the number of internal parts and greatly increases the input pressure. The system is equipped with three levels of filtration, two cloth bag stainless steel filters at the end, and the final filter bag accuracy reaches 1 micron.

We Recommend

Surface Cleaner Water Blaster Roof Cleaning Machine

15HP Pressure Washing Pump Suppliers 52lpm 100bar JPD5210

New Arrivals

New products from manufacturers at wholesale prices