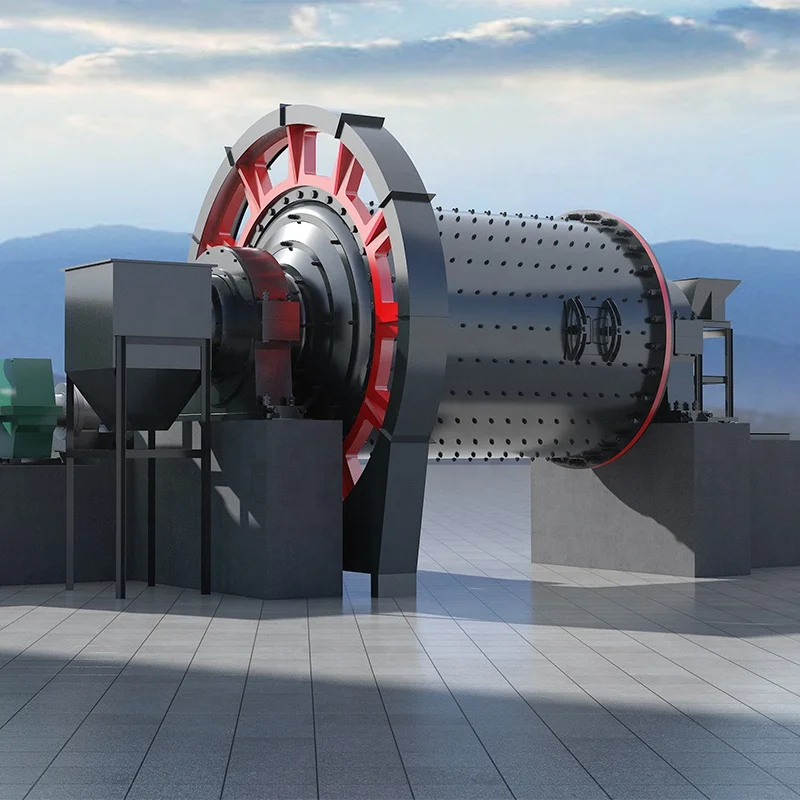

Dry and Wet Grinding Ball Mill Machine for Gold Ore/Quartz/Cement/Limestone for Sale

- Category: >>>

- Supplier: Henan Fote Heavy Machinery Co. Ltd.

Share on (1601045247934):

Product Overview

Description

Product Description

The ball mill is a grinder that finely grinds crushed materials (≤25 mm) to 20-200 mesh through dry grinding and wet grinding. Wet operations are usually equipped with classifiers, while dry operations are equipped with dust collectors.

The ball milling machine is suitable for primary grinding (crushers + ball mill) and secondary grinding stages (crushers + rod mill + ball mill), and is used in conjunction with the crushers and beneficiation equipment in the mineral processing plant.

Its applicable materials include metal ores, non-metallic ores, cement clinker, slag, quartz sand, zircon sand, glass, ceramics, new building materials, etc. Thus, it is widely used in cement, building materials, fireproof materials, glass, ceramics, and other industries.

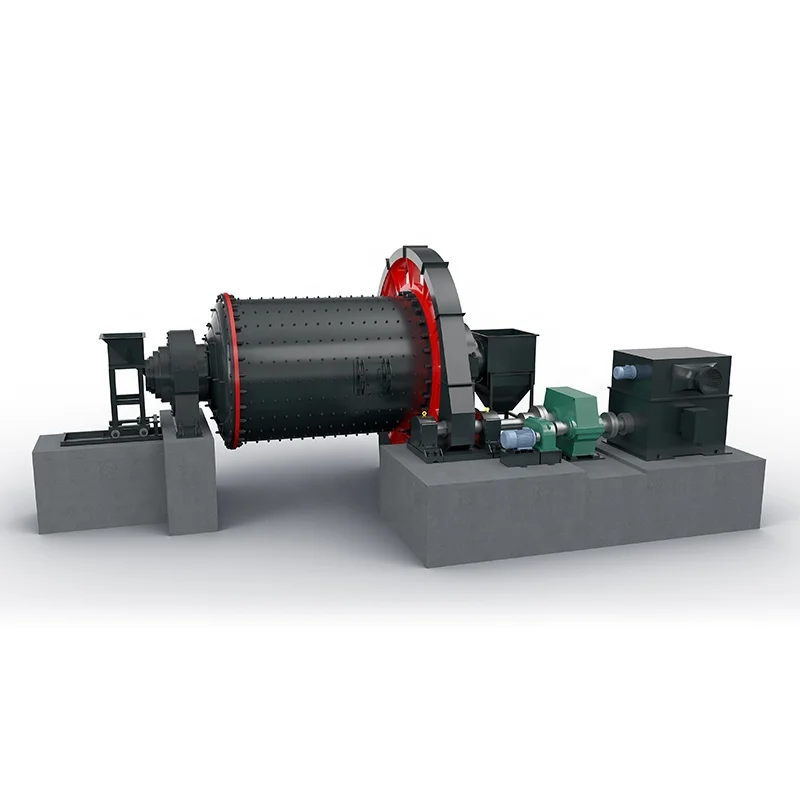

The Structure of the Ball Mill

The impact crushers usually form a complete crushing system with the jaw crusher. The system handles various types of mineral, rock and aggregate products. Please refer to the device's parameter sheet or consult us for details.

Ball Mill Working Principle

1. When the ball mill works, it is driven by the outer gear. Materials enter the mill through the feeding device. There are wear-resistant lining plates and grinding balls of different specifications in the cavity.

2. The rotation of the cylinder generates centrifugal force, which brings the ball to a certain height and then falls, causing a heavy impact and grinding effect on the material.

3. The powdery material is discharged through the discharging port to complete the grinding.

Check out the video on how a ball mill works

Globally recognized performance

- Simple structure, full hydraulic operation, and easy maintenance.

- Large output and it can be operated intermittently or continuously.

- The output size is fine and uniform.

- The cylinder and grinding balls are wear-resistant. Appropriate liner plates (high manganese steel, rubber, and magnetic lining plates) can be selected. Liner thickness (50-150 mm) is determined according to the diameter of the mill.

- Small ball mills use anti-friction cylindrical roller bearings. Large ball mills use trunnion bearings and hydrostatic bearings.

- The quill shaft is made of cast steel, the liner is removable, and the large gear adopts casting hobbing process.

- Grinding is carried out in a closed machine, forming a closed system with the classifier to avoid dust and noise pollution.

The supply scope of our ball mill

- Complete set of ball mill equipment, including: Cylinder, large gear, pinion gear, gear cover, liner plate, motor, gearbox, electric cabinet, foundation bolts, sizing block etc.

- Grinding media are excluded. Different sizes of grinding balls (aluminum ceramic balls or steel grinding balls) are available for sale.

- Optional: Slow speed drive device, high and low-pressure lubrication station, gear spray lubrication device, and PLC control system.

| Model | Ball load (t) | Feeding size (mm) | Discharging size (mm) | Capacity (t/h) | Motor power (kw) | Total weight (t) |

| 900×3000 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| 1200×4500 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| 1500×4500 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| 1500×5700 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| 1830×3000 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| 1830×4500 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| 2100×3000 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| 2100×4500 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| 2100×7000 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| 2200×4500 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| 2200×6500 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| 2200×7000 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| 2400×4500 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| 2700×4500 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| 3600×4500 | 90 | <25 | 0.074-0.4 | As per process conditions | 850 | 169 |

| 3600×6000 | 110 | <25 | 0.074-0.4 | As per process conditions | 1250 | 198 |

| 4000×5000 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 |

Henan Fote Heavy Machinery Co., Ltd was founded in 1982 in Zhengzhou, Henan, the capital of Chinese machinery manufacturing. The company is large in scale and has four major production bases with a total area of 500,000 square meters, of which standardized heavy industry plants cover an area of 360,000 square meters, providing advanced and reliable infrastructure for production.

Our company focuses on the development and production of mining machinery, including crushers, mills, beneficiation equipment, briquette machines, rotary kilns and other products, which are widely used in mining, chemical industry, construction, coal, ceramics, and other industries. With excellent quality and professional solutions, it has won the trust of customers around the world.

1. We provide customers with a full range of services, including solution design, technical process planning, and the design and manufacturing of standard and non-standard equipment.

2. We dispatch professional technicians to the customer site to assist with shell welding, equipment installation, adjustment, and training of operators.

3. We visit customers regularly to provide lifelong service and technical support.

4. Except for wearing parts, we provide one-year warranty, long-term supply of spare parts, and two-year maintenance of major parts if used correctly.

1. Our equipment holds ISO 9001, CE, and GOST certifications and all equipment undergoes pre-wiring, assembled, and factory tested at our manufacturing facility.

2. We take a test on each machine before delivery.

1. How to get the best price for equipment?

- We are the direct manfacturer, so we can offer you the lowest price than the market price.

- The price of the machine can be given the largest discount based on quantity.

2. Our payment term

- Paypal, T/T, L/C, and Western Union are all available.

- 30% deposit in T/T advance, 70% balance before shipment.

- We take photos of finished products before delivery.

3. Delivery time

- Streamlined production allows for prompt delivery of most products within 6-8 weeks.

- The delivery time will be based on the machine type, selected shipping method, and parts availability.

4. Packaging

- The equipment is wrapped in plastic film before packaging to avoid moisture at sea.

- Bare machines are packed in export containers.

- The motors and small parts are packed in waterproof, sealed, and sturdy wooden cases.

5. Transportation

- Standard container or bulk cargo transportation.

- Sea transportation, air transportation, land transportation, according to customer requirements.

- Complete shipping options and best services at lowest prices are provided: MSC, APL, COSCO, OOCL, CSCL, MSC, MSK, KLINE, etc.

- Seaports in normal use: Qingdao, Tianjin, Shanghai.

- We promise that your goods will be delivered to the destination promptly and safely, and will remind you before the ship arrives.

If you need quality machinery with the latest technology, best prices and fastest delivery, our company is your answer. You are welcome to visit our company and workshop, we sincerely look forward to cooperating with you.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices