Ss Cartridge Filter Housing For Water Purification Stainless Steel Series Multi Cartridge Filter Housing chamber

- Category: >>>

- Supplier: Qingdao Crowns Machinery Co. Ltd.Qingdao Ltd.

Share on (1601046759746):

Product Overview

Description

Swing Bolt Closure SS Housings are designed for general purpose commercial and industrial filtration needs.

Heavy-duty 304L or 316L stainless steel construction with Swing Bolt Closure for maximum durability.

Swing bolt closure is quick and easy to change cartridges and secures sealing.

Plenty of cartridges can service a wide range of higher flow rates.

Flange inlet and outlet connections allow for easy piping drain connections permit quick evacuation of housing.

Equipped with heavy-duty stainless steel mounting legs.

Holds cartridges from 20” to 40” lengths for optimal choice of flow rates.

Wide range of options to meet specific filtration and installation requirements

Heavy-duty 304L or 316L stainless steel construction with Swing Bolt Closure for maximum durability.

Swing bolt closure is quick and easy to change cartridges and secures sealing.

Plenty of cartridges can service a wide range of higher flow rates.

Flange inlet and outlet connections allow for easy piping drain connections permit quick evacuation of housing.

Equipped with heavy-duty stainless steel mounting legs.

Holds cartridges from 20” to 40” lengths for optimal choice of flow rates.

Wide range of options to meet specific filtration and installation requirements

Features:

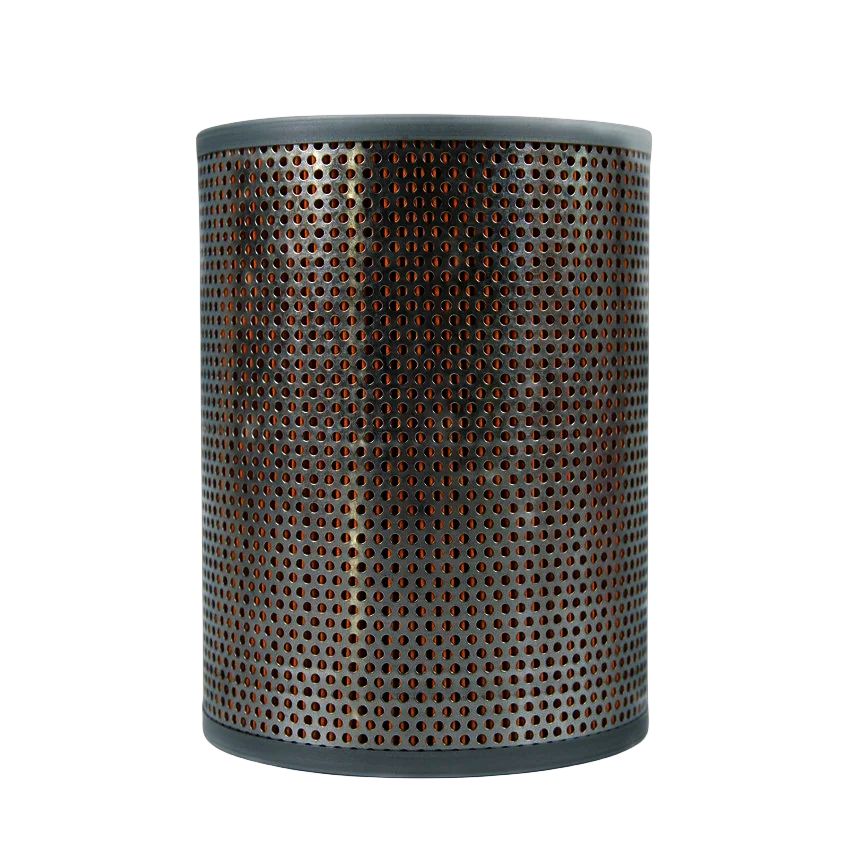

1. Easy to clean and reusable2. Large number of openings and uniform structure, low filtration resistance

3. longer service life than screen filter and ceramic filter

4. Special technology with high strength and high temperature rolling

5. High temperature resistance and corrosion resistance; Good permeability; Uniform filtration

CROWNS MACHINERY

With advanced production equipment, strong R&Dability, and testing equipment all at high state of readiness, Crownwig can satisfy

a variety ofprofessionally customized requirements. After years of unremitting efforts, the company has won high praise from its customers regardingits strict quality management and high-quality after-sales service, the well-known large customersaccounting for up to 95%.

a variety ofprofessionally customized requirements. After years of unremitting efforts, the company has won high praise from its customers regardingits strict quality management and high-quality after-sales service, the well-known large customersaccounting for up to 95%.

Crownwig assists customers to win a lot of government bidding proiectstogether .

Q1 : Where is your factory located?

A1 : Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

Q2 : Are you an integrated supplier for industrial filter machine ?

A2 : Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3 : How about the quality control in your factory?

A3 : Qingdao crowns has the SOP (Standard Operation Procedure) and all the production step must follow

up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully

before shipment.

Q4 : Will you offer the pre-sales service?

A4 : Yes, we have an experienced pre-sales team to support customers not only including machine, technology

also water electrical,machine layout in factory, etc.

Q5 : What about the after-service? Will you send your engineer to my country to help commission and install the

machine?

A5 : Surely, we have many experience technical engineers for oversea service, they would help you install machine

and support training to workers also.

Q6 : What is the delivery time of the machine?

A6 : Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery

time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7 : The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8 : Yes, CROWNS will provide one set standard spare parts to customer according to different machines

A1 : Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

Q2 : Are you an integrated supplier for industrial filter machine ?

A2 : Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3 : How about the quality control in your factory?

A3 : Qingdao crowns has the SOP (Standard Operation Procedure) and all the production step must follow

up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully

before shipment.

Q4 : Will you offer the pre-sales service?

A4 : Yes, we have an experienced pre-sales team to support customers not only including machine, technology

also water electrical,machine layout in factory, etc.

Q5 : What about the after-service? Will you send your engineer to my country to help commission and install the

machine?

A5 : Surely, we have many experience technical engineers for oversea service, they would help you install machine

and support training to workers also.

Q6 : What is the delivery time of the machine?

A6 : Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery

time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7 : The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8 : Yes, CROWNS will provide one set standard spare parts to customer according to different machines

We Recommend

New Arrivals

New products from manufacturers at wholesale prices