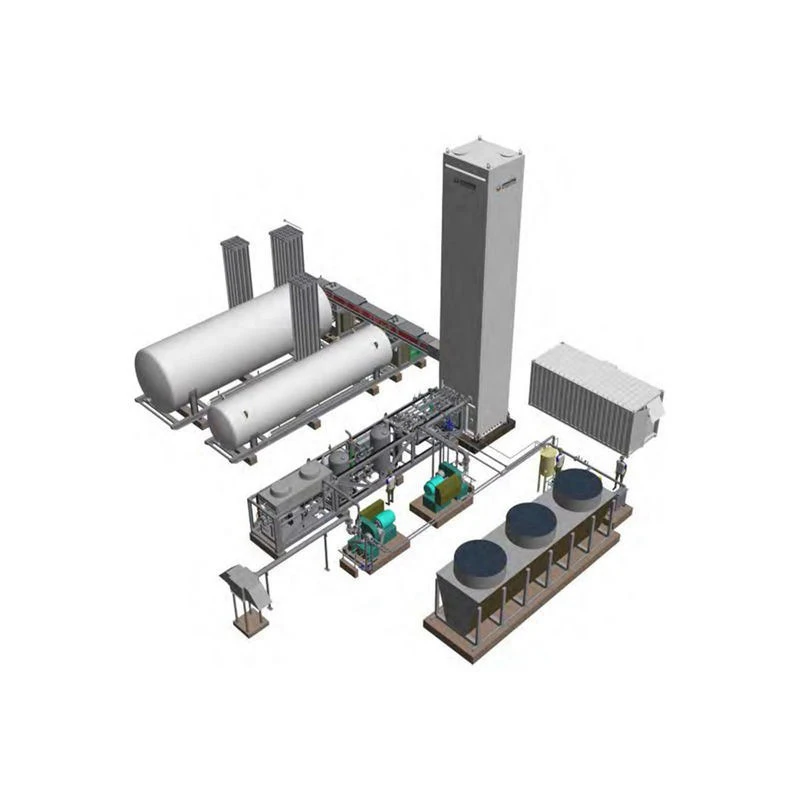

Helium Generator Helium Separation Extraction Device He Production Machine With Helium Liquefier Refrigerator

- Category: >>>

- Supplier: Wobo Industrial Group Corp.

Share on (1601049862929):

Product Overview

Description

Membrane Helium Recovery & Purifcation System

Industrial Helium Capture Device Food Grade Helium 99.999% Gas Generator Recovery Plant From Natural Gas for Sale

Technical Principle

Gas separation membranes are specialized materials, either polymer or inorganic, that exploit differences in solubility and diffusion coefficients to separate gas mixtures. These membranes classify gases into "fast" and "slow" based on their permeation rates. Under pressure differences, fast gases like water, hydrogen, helium, and carbon dioxide permeate through the membrane, while slow gases like methane, nitrogen, carbon monoxide, and argon are retained. The WOBO series utilizes this principle with

semi-permeable hollow filaments to separate gases. Compared to standard membrane specifications, WOBO offers customized, safer, and more stable gas pathways and fittings.

semi-permeable hollow filaments to separate gases. Compared to standard membrane specifications, WOBO offers customized, safer, and more stable gas pathways and fittings.

Product Description

LNG BOG Helium Recovery System

Taking LNG BOG as the raw material, the process involves multiple pretreatments and precleaning steps, including but not limited

to oil removal, water removal, cryogenic separation purification, recooling, pressurization, drying, decarbonization, etc. The resulting gas mixture contains a higher concentration of helium (He) along with significant amounts of impurities such as methane (CH4) and nitrogen (N2). The process includes membrane separation for helium enrichment, PSA refinement, alloy helium separation,TSA purification, and other steps to individually remove CH4, N2, and Ne, extracting high-purity helium products.

to oil removal, water removal, cryogenic separation purification, recooling, pressurization, drying, decarbonization, etc. The resulting gas mixture contains a higher concentration of helium (He) along with significant amounts of impurities such as methane (CH4) and nitrogen (N2). The process includes membrane separation for helium enrichment, PSA refinement, alloy helium separation,TSA purification, and other steps to individually remove CH4, N2, and Ne, extracting high-purity helium products.

LNG BOG Helium-Hydrogen Recovery System Process Input Parameters | ||||||||||||

Pressure | 18~20barg | |||||||||||

Temperature | 20℃ | |||||||||||

Raw Helium Flow Rate | 300Nm3/h (7200Nm3/day)(Operational Flexibility: 50%~110%) | |||||||||||

Composition | CH | CH | N | H0 | Hz | CO2 | ||||||

Composition (mol/mol%) | 2 | 0 | 92.57 | 4.38 | 1.05 | 0 | ||||||

Process Output Parameters:

* He Product Purity: 99.999% mol

* He Product Pressure: ≥200 barg

* He Product Yield: ≥97%

H2 Product Specifications:

* H2 Product Purity: ≥99.999% mol

* H2 Product Pressure: 1~50 barg

(adjustable based on hydrogen release temperature)

* H2 Product Yield: ≥95%

Integrated Utilization System for Natural Gas/Coalbed Methane/Shale Gas

Taking natural gas/coalbed methane/shale gas as raw materials, the process involves multiple pretreatments and precleaning steps,

including low-temperature fractional distillation, membrane separation for He/H2 concentration, PSA refinement for He/H2

purification, alloy He/H2 separation, TSA removal of Ne, etc., to individually remove CH4, N2, etc. The final result is the extraction of high-purity He, electronic-grade H2, liquid C2H6, LPG, and LNG (or pipeline natural gas).

including low-temperature fractional distillation, membrane separation for He/H2 concentration, PSA refinement for He/H2

purification, alloy He/H2 separation, TSA removal of Ne, etc., to individually remove CH4, N2, etc. The final result is the extraction of high-purity He, electronic-grade H2, liquid C2H6, LPG, and LNG (or pipeline natural gas).

Process Input Parameters | ||||||||||||||

Pressure | 60barg | |||||||||||||

Temperature | 25℃ | |||||||||||||

Raw Helium Flow Rate | 50000Nm3/h(Operational Flexibility: 50%~110%) | |||||||||||||

Composition | CH | C2H6 | CHy (x>2) | N2 | He | H2 | CO2 | |||||||

Composition (mol/mol%) | 86.35 | 7 | 1 | 0.6 | 0.04 | 0.01 | 5 | |||||||

Process Output Parameters:

He Product Specifications:

* He Product Purity: 99.999% mol

* He Product Pressure: ≥200 barg

* He Product Yield: ≥97%

H2 Product Specifications:

* H2 Product Purity: ≥99.999% mol

* H2 Product Pressure: 1~50 barg (adjustable based on hydrogen release temperature)

* H2 Product Yield: ≥95%

C2H6 Product Specifications:

* C2H6 Product Purity: ≥99% mol

* C2H6 Product Pressure: ≥2.5 bara

* C2H6 Yield: ≥98%

LPG Product Specifications:

* LPG Product Purity: ≥99% mol

* LPG Product Pressure: ≥2.5 bara

* LPG Yield: ≥98%

LNG Product Specifications :

* LNG Product Purity: ≥99% mol

* LNG Product Pressure: ≥2.5 bara

* LNG Yield: ≥98%

* He Product Purity: 99.999% mol

* He Product Pressure: ≥200 barg

* He Product Yield: ≥97%

H2 Product Specifications:

* H2 Product Purity: ≥99.999% mol

* H2 Product Pressure: 1~50 barg (adjustable based on hydrogen release temperature)

* H2 Product Yield: ≥95%

C2H6 Product Specifications:

* C2H6 Product Purity: ≥99% mol

* C2H6 Product Pressure: ≥2.5 bara

* C2H6 Yield: ≥98%

LPG Product Specifications:

* LPG Product Purity: ≥99% mol

* LPG Product Pressure: ≥2.5 bara

* LPG Yield: ≥98%

LNG Product Specifications :

* LNG Product Purity: ≥99% mol

* LNG Product Pressure: ≥2.5 bara

* LNG Yield: ≥98%

Project Case

Application: Natural gas

Capacity: 24,000 Nm3/day

Operation pressure: 64-68 barg

He feed concentration: 542 ppm

He enrichment: >10 times

He recovery: >85%

Application: LNG/BOG

Capacity: 380 Nm3/h

He concentration in feed: 13.3%

Purities of (He+H2) > 95%

Recovery of (He+H2) > 96%

Capacity: 380 Nm3/h

He concentration in feed: 13.3%

Purities of (He+H2) > 95%

Recovery of (He+H2) > 96%

The advantages of membrane technology include, but are not limited to, the following:

1) Fast action, simply operated, qualified product obtained following starting;

2) Delicate and compact, fully modular configuration and combination;

3) No moving parts, low failure rate and highly reliability

4) Flexibility to obtain the maximum yield in a multi-stage manner to achieve optimization and replacement of existing production processes;

5) Highly stability of purity, flow rate and pressure;

6) The product gas can be purified to more than 99%mol under the condition of the lowest product gas loss rate.

Product Application

Company Profile

We Recommend

Cryogenic air Separation Unit Gas with Two Columns Oxygen Nitrogen Producing Manufacturers

$170,000.00-180,000.00

New Arrivals

New products from manufacturers at wholesale prices