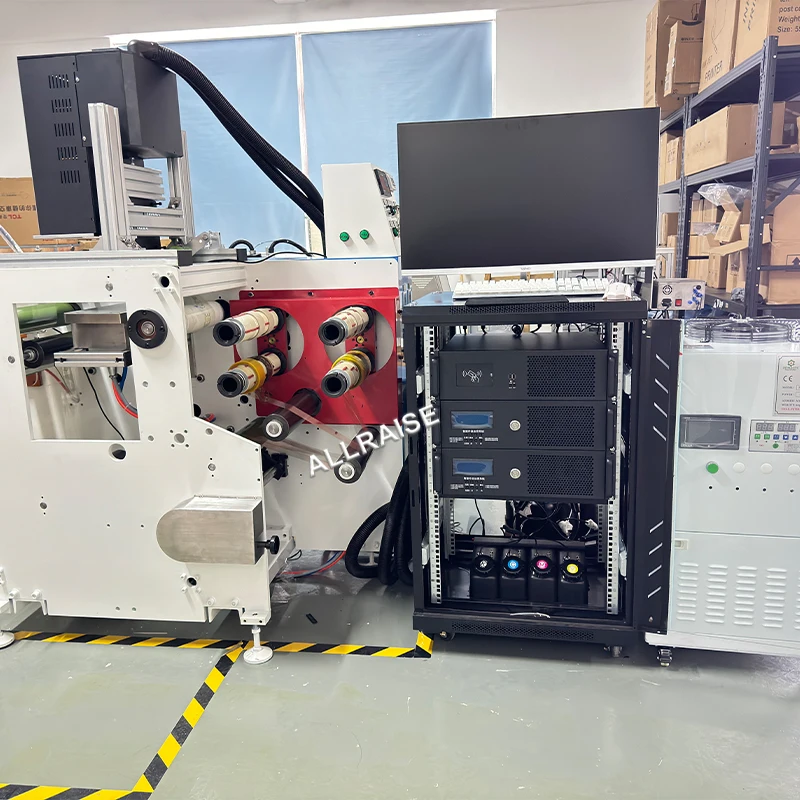

High Quality PVC BOPP PET Inkjet UV Printer Machine Mobile Phone Case Paper Film Inkjet Printer For Small Business

- Category: >>>

- Supplier: Zhengzhou Allraise Company Ltd.

Share on (1601054892245):

Product Overview

Description

High Quality PVC BOPP PET Inkjet UV Printer Machine Mobile Phone Case Paper Film Inkjet Printer For Small Business

Product Parameters

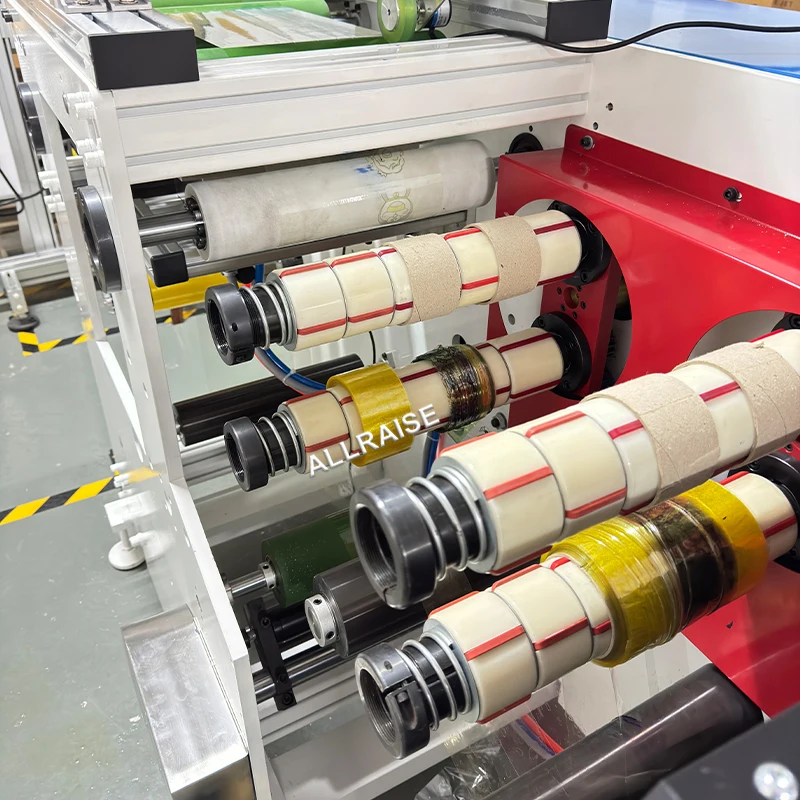

Nozzle type | Industrial piezoelectric nozzle (RICOH nozzle) |

Nozzle life | 100Billion actuation,s per nozzle |

Printing materials | suitable for materials with strong diffusion such as non-woven fabrics |

Nozzle width | single head 216mm (built-in 4 groups of nozzles and 8 Ricoh G5 nozzles) |

Number of holes in a single nozzle | 1280 Number of holes in a single row: 640 |

Number of rows of a single nozzle | 2 rows (1 row of holes for 1 color 300dpi, 2 rows of holes 600dpi) |

Printing module | (standard) single set of nozzles with built-in 2 sets of G5 nozzles (CMYK four colors) |

Printing speed | 0-60 meters/minute (determined by factors such as material/resolution/environment/platform) |

Working environment | Temperature: 5℃-40℃ |

Interface type | USB3.0 and optical fiber data transmission |

Printing software | MagicData variable data editing software |

Secondary development | The software provides interfaces to support secondary development |

Ink path control | negative pressure ink path control, positive pressure nozzle cleaning |

Ink type | environmentally friendly UV ink |

Curing type | LED-UV curing |

Nozzle lateral accuracy | 300dpi-1200dpi adjustable |

The starting printing resolution of this information is | 300dpi-adjustable |

Longitudinal accuracy of nozzle | single row of holes 300dpi, double row of holes 600dpi |

Humidity | 10%--80% (non-condensing state) |

Product Features

1. | The machine uses a modular design, making maintenance simple and convenient. Each nozzle has independent positive and negative pressure control, and the negative pressure accuracy is as high as 0.01kpa. Each nozzle can precisely adjust and control the ink pressure. |

2. | The machine's specially designed composite secondary ink cartridge ensures that it is suitable for all types of inks and is compatible with water-based, solvent, and UV. |

3. | The machine uses independent protection stop valves for positive pressure and negative pressure air circuits, double stop valves for the ink circuit, and dual-circuit constant temperature heating for ink supply. It can be used when the machine is turned on,and can be turned off and left to prevent leakage and dripping of ink. |

4. | The machine develops special software for variable data digital inkjet systems specifically for the variable data industry to ensure that all types of barcodes, QR codes, and databases can be realized. |

5. | The machine customizes ultra-black ink to ensure blackness accuracy and reduce production costs. |

6. | Each nozzle of the machine has an independent data processing core, regardless of cost, just for high speed and stability. |

7. | Machine parameter centralized control system, independent human-machine control interface, simplifying complexity. |

8. | When the machine uses a UV lamp, the light intensity automatically adjusts with the speed to ensure that different speed ranges can meet the curing requirements without damaging the product. |

Hot Sell

Contact Us

Package&Shipping

Package detail | Wooden Case |

Delivery detail | within 10-30 working days after receiving your prepayments |

Shipment detail | Express,sea,truck,airplane etc. |

Payment terms | T/T, L/C, Paypal, Western union,Alibaba trade assurance etc. |

About Us

1)Your reply will be replied within 12 hours.

2)Fast delivery time and good after service.

3)Freight forwarder: faster, safer and convenient.

4)Good factory price.

5)Provided test videos and packing pictures before shipping

6)Welcome to visit our factory at any time!

FAQ

Don't worry your TT payment,we do make the shipment as T/C,B/L for yourreference!

Q: Why don't person reply to me?

A: Our person is 24 hours on-line. If nobody reply you , maybe he has other businesses temporarily. So please leave your requirements on e-mail or chat tool, we will reply you as soon as possible.

Q: Can you guarantee your quality?

A:Of course. We are the manufacture factory. More important, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

Q: How do you make your price?

A: We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture. You will get lower.

A: Our person is 24 hours on-line. If nobody reply you , maybe he has other businesses temporarily. So please leave your requirements on e-mail or chat tool, we will reply you as soon as possible.

Q: Can you guarantee your quality?

A:Of course. We are the manufacture factory. More important, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

Q: How do you make your price?

A: We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture. You will get lower.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices