Modular Laboratory Cleanroom Door Hinges

- Category: >>>

- Supplier: Shandong Wiskind Architectural Steel Co. Ltd.

Share on (1601062552357):

Product Overview

Description

Product Description

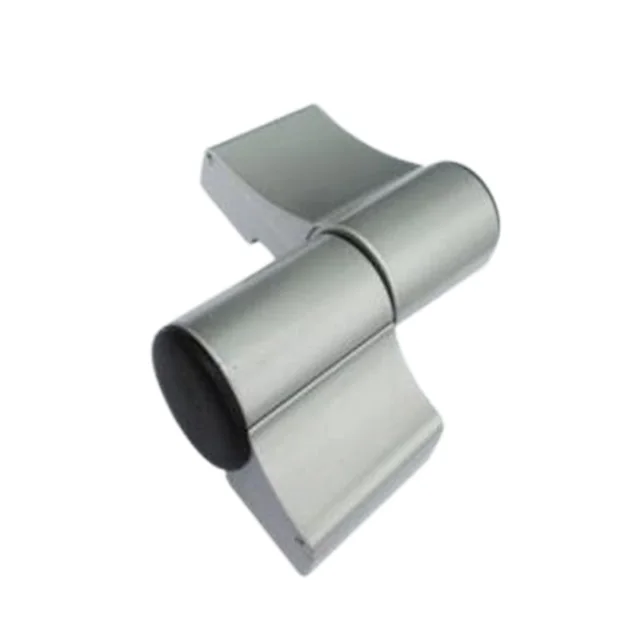

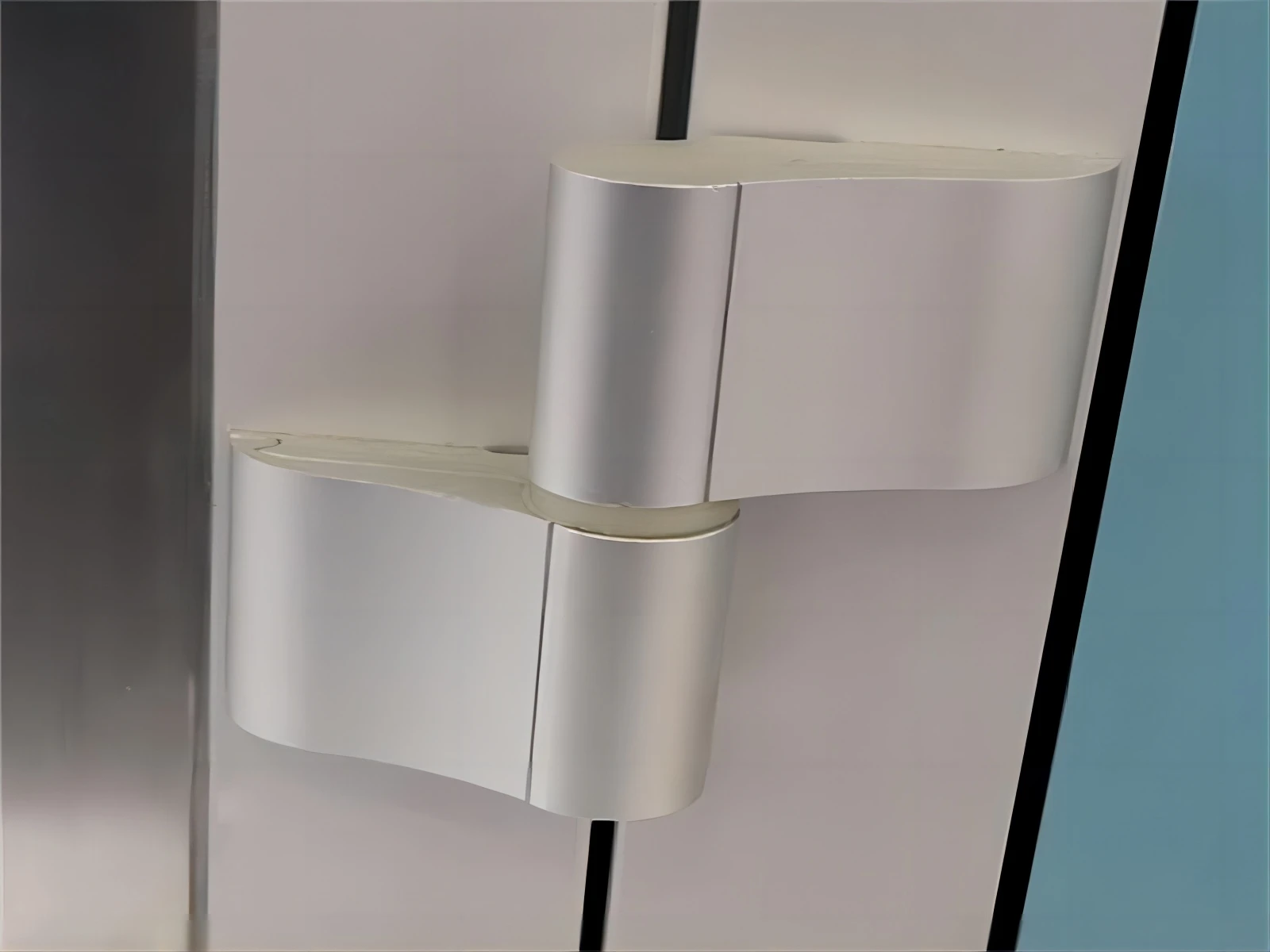

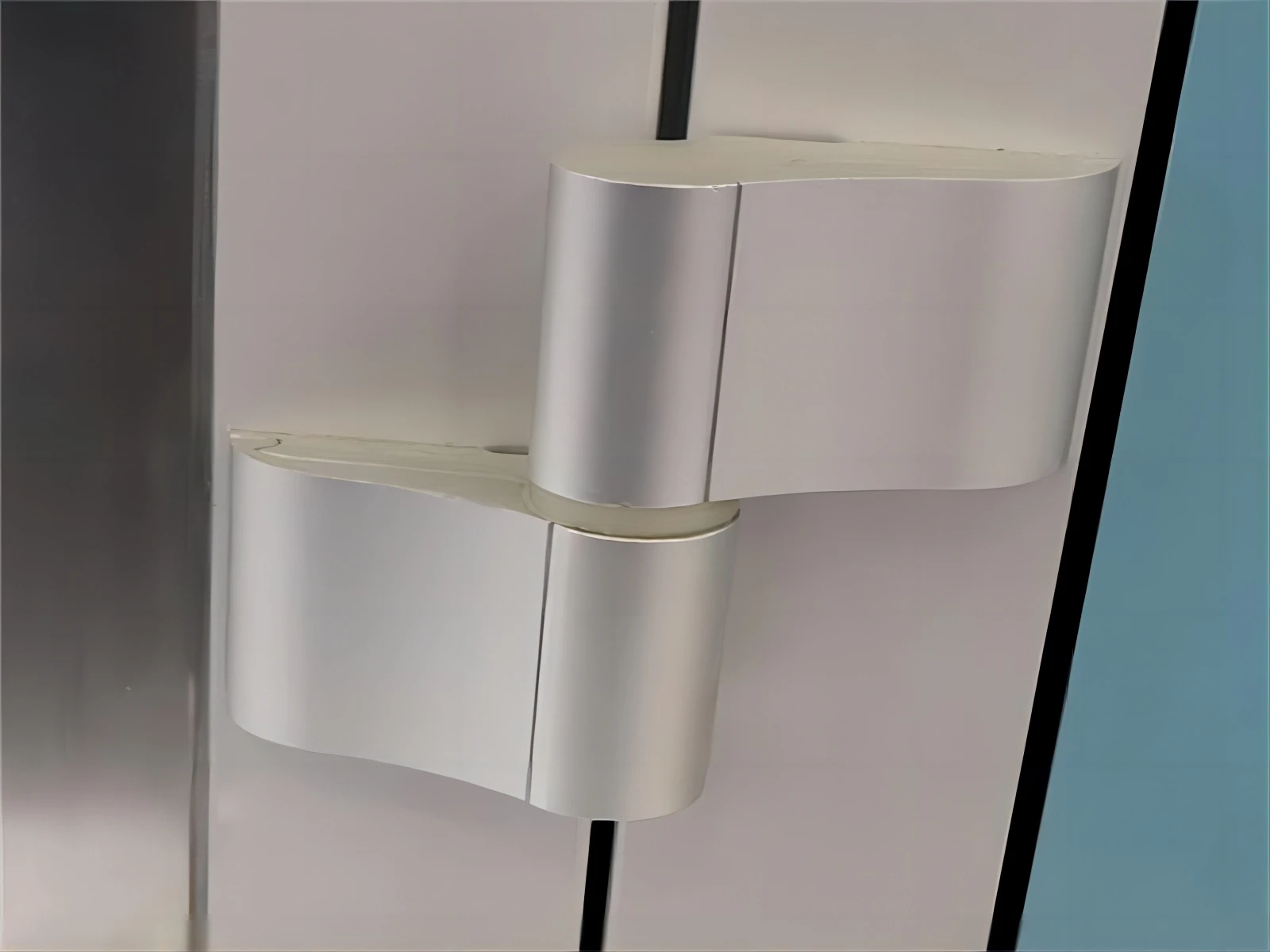

Wiskind hinges are divided into two types, 304 stainless steel hinges, convenient for on-site installation and commissioning, durable; aluminum alloy hinges, beautiful and generous, no dust, easy to clean, acid and alkali resistant. Widely used in clean rooms such as pharmaceuticals, electronics, and food.

Specification

GEZE Cleanroom Locks:

Aluminum alloy hinge:optional Wiskind patentable adjustable clean hinge,beautiful and generous, no dust, easy to clean, durable, resistant to acid and alkali disinfection, with patented door seam adjustable function; (standard is not adjustable version)

How to Choose a Cleanroom Door Thing

When buying a cleanroom door, in addition to choosing a good-quality, cost-effective hinge to ensure durability and easy cleaning, other requirements must also be paid attention to. The following are Wiskind's views that each customer must consider before choosing a cleanroom door Thing.

1.Easy to integrate

When choosing a cleanroom door, be aware that many manufacturers sell only the doors in their systems. This makes it difficult to change parameters within the facility to compromise the integrity of the cleanroom door. However, regardless of the manufacturer, the Wiskind cleanroom door can be installed in any cleanroom. The thickness of the door is 50mm, which is flush with the cleanroom wall panel, with higher flatness and a more beautiful appearance.

1.Easy to integrate

When choosing a cleanroom door, be aware that many manufacturers sell only the doors in their systems. This makes it difficult to change parameters within the facility to compromise the integrity of the cleanroom door. However, regardless of the manufacturer, the Wiskind cleanroom door can be installed in any cleanroom. The thickness of the door is 50mm, which is flush with the cleanroom wall panel, with higher flatness and a more beautiful appearance.

2. Good sealing performance

In the cleanroom door leaf seal, it should be noted that the seals around the clean door of the large department on the market are made of ordinary sealing strips. The structure is unstable, and the long-term use will cause the falling off phenomenon, and the airtightness in the cleanroom cannot be guaranteed, resulting in cleanliness. Loss of pressure inside the room.

Wiskind cleanroom door seals are made of (air, ship, precision electrical cabinet industry) German equipment, German technology, German polyurethane glue on-site foam production, stable structure, not easy to fall, life is ordinary adhesive rubber seal 4 to 5 times It can resist UV, alcohol and other disinfection. It is not easy to age under a frequent disinfection environment. It is non-toxic and harmless to the human body. It has excellent airtightness and can effectively prevent the pressure inside the cleanroom from being lost and ensure the airtightness in the cleanroom.

3. Door lock selection

In the cleanroom door leaf seal, it should be noted that the seals around the clean door of the large department on the market are made of ordinary sealing strips. The structure is unstable, and the long-term use will cause the falling off phenomenon, and the airtightness in the cleanroom cannot be guaranteed, resulting in cleanliness. Loss of pressure inside the room.

Wiskind cleanroom door seals are made of (air, ship, precision electrical cabinet industry) German equipment, German technology, German polyurethane glue on-site foam production, stable structure, not easy to fall, life is ordinary adhesive rubber seal 4 to 5 times It can resist UV, alcohol and other disinfection. It is not easy to age under a frequent disinfection environment. It is non-toxic and harmless to the human body. It has excellent airtightness and can effectively prevent the pressure inside the cleanroom from being lost and ensure the airtightness in the cleanroom.

3. Door lock selection

The number of times the cleanroom door lock of the door is locked is the key factor determining the life of the door lock. When selecting the cleanroom door lock, pay attention to whether the number of the door opening and closing times of the door lock has special experimental report data to determine the service life. Also, consider different door lock types at different locations.

4. Quality after-sales service

Determine the specifications of the cleanroom door. When selecting a supplier, whether it is a large company or a small company, look at the services provided, whether there is a professional team to solve the problems encountered, including the confirmation of the drawings and the accessories of the door. The high-quality service is to avoid the problem of door replacement, and thus pay a higher cost.

4. Quality after-sales service

Determine the specifications of the cleanroom door. When selecting a supplier, whether it is a large company or a small company, look at the services provided, whether there is a professional team to solve the problems encountered, including the confirmation of the drawings and the accessories of the door. The high-quality service is to avoid the problem of door replacement, and thus pay a higher cost.

Manufacturing Technique

Technology & craftsmanship of the Wiskind Cleanroom Doors

Wiskind from the domestic introduction of advanced cleanroom doors production equipment up to more than 20 sets, from raw materials to doors products off the line, high-precision automation production process in the industry occupies a leading position, to first-class product quality to meet the fierce market demand.

Wiskind with Italian PrimaPower PuMa treasure - before full import sheet metal production lines, with automatic control of feeding positioning shearing machine, CNC bending machine, and adopts many sets of Japan YASKAWA robot welding automation and the international advanced aluminum alloy doors and windows equipment, can use the international latest technology and equipment to ensure product quality, further exert their own advantages, better service to customers, enhance the brand image.

Wiskind with Italian PrimaPower PuMa treasure - before full import sheet metal production lines, with automatic control of feeding positioning shearing machine, CNC bending machine, and adopts many sets of Japan YASKAWA robot welding automation and the international advanced aluminum alloy doors and windows equipment, can use the international latest technology and equipment to ensure product quality, further exert their own advantages, better service to customers, enhance the brand image.

Company Profile

Wiskind, founded in 1978, specializes in the cleanroom enclosure system,with over 66,66,66㎡ area and 2,000 staffs.With over 40year’s development,Wiskind has rich experiences in designing, manufacturing, transportation and installation of cleanroom systems. We have been committed to providing customers with the most reasonable and economical solutions. We specialize in biomedicine, electronic, semiconductor, food, new energy and other industries. We have a complete product system and rich product categories, such as cleanroom panels, cleanroom doors, medical doors, cleanroom windows and other products, with FM, CE, SGS, ISO9001,ISO14001 certifications. In the past 40 years, Wiskind has exported to more than 50 countries and regions,and trusted by local and international clients.We keep investing in product R&D, improving client services, and increasing partnerships.

Exhibition

Production Line

Product packaging

Our Customers

Project Cases

FAQ

1. Are you a Factory/Manufacturer Or Trading Company?

We are a manufacturer with 41 years' experience of production and have a modern standard plant of 1,000,000 m².

2.How about your lead time?

It will take 3-7 days for budget and design according to the drawings after receiving the deposit. 15-30 days if there are some

special sizes.

3. Can you sell products all over the world?

Yes, we have 4 subsidiaries, 13 offices, and more than 100 technical supervisors all over the world, providing timely and

face-to-face service for customers.

4.How about your core competitiveness?

We have the first automatic production line in the world. Compared with the traditional manual production line, the production

efficiency increased by 6-8 times, leading to most competitors. That means lower cost and higher quality.

5. Do you have your own construction team?

No, but all of our cleanroom panels and connected parts are easy for disassemble and installation due to our excellent design. What's more, we provided the instruction and videos for installation and we can send our professional supervisor to the site.

6. How many kinds of products do you have?

At present, we have more than 30 different products, including a cleanroom wall panel system, ceiling system, clean room door,

clean room window and so on.

7. Can you provide samples? Is it free or extra?

Yes, we can provide samples for free, but we would appreciate it if freight to collect.

8. What are your terms of payment?

30% T/T prepaid, 70% T/T before delivery. We can discuss payment if we have more cooperation in the future.

We are a manufacturer with 41 years' experience of production and have a modern standard plant of 1,000,000 m².

2.How about your lead time?

It will take 3-7 days for budget and design according to the drawings after receiving the deposit. 15-30 days if there are some

special sizes.

3. Can you sell products all over the world?

Yes, we have 4 subsidiaries, 13 offices, and more than 100 technical supervisors all over the world, providing timely and

face-to-face service for customers.

4.How about your core competitiveness?

We have the first automatic production line in the world. Compared with the traditional manual production line, the production

efficiency increased by 6-8 times, leading to most competitors. That means lower cost and higher quality.

5. Do you have your own construction team?

No, but all of our cleanroom panels and connected parts are easy for disassemble and installation due to our excellent design. What's more, we provided the instruction and videos for installation and we can send our professional supervisor to the site.

6. How many kinds of products do you have?

At present, we have more than 30 different products, including a cleanroom wall panel system, ceiling system, clean room door,

clean room window and so on.

7. Can you provide samples? Is it free or extra?

Yes, we can provide samples for free, but we would appreciate it if freight to collect.

8. What are your terms of payment?

30% T/T prepaid, 70% T/T before delivery. We can discuss payment if we have more cooperation in the future.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices