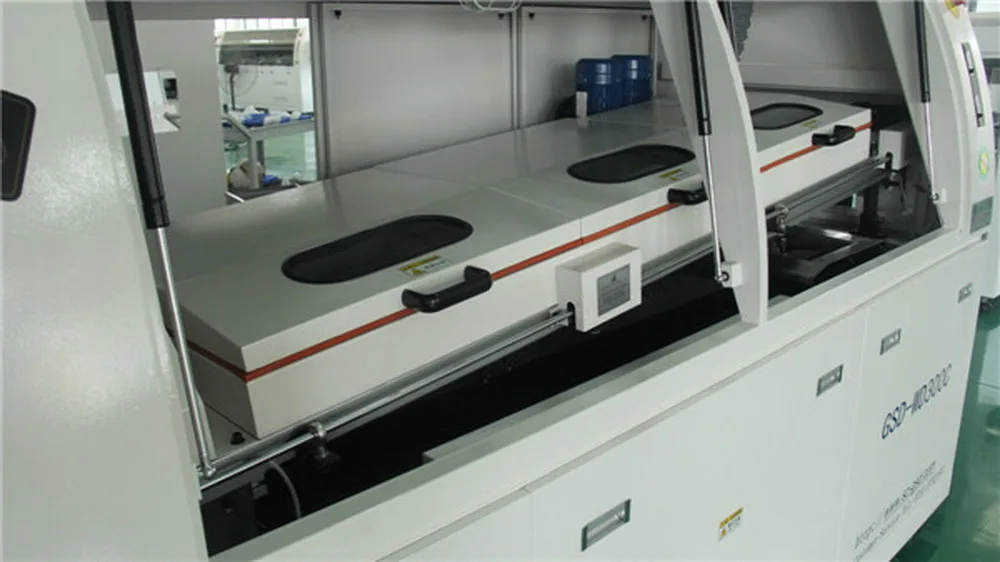

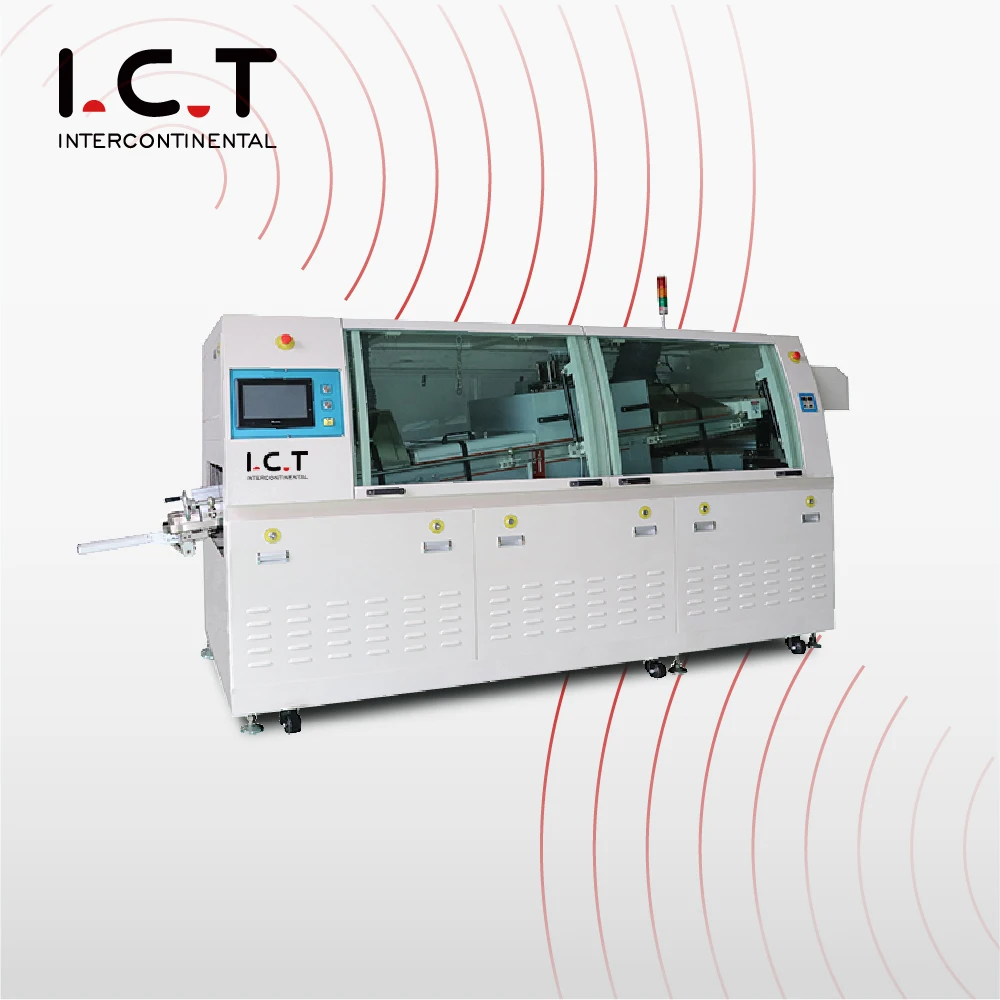

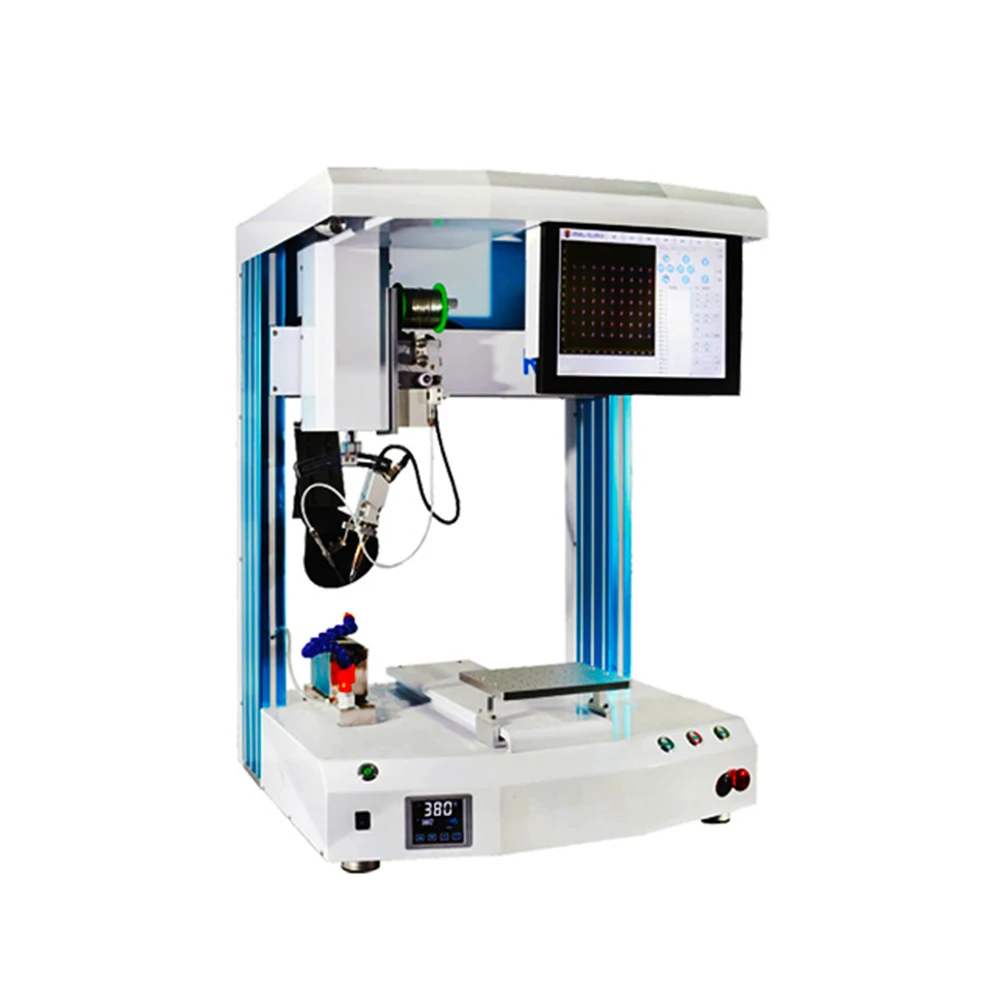

GRANDSEED factory price Automatic SMT Wave soldering GSD WD300C DIP Wave Soldering Machine

- Category: >>>

- Supplier: Shenzhen Grandseed Technology Development Co. Ltd.

Share on (1601069892005):

Product Overview

Description

SPECIFICATIONS | |

ITEMS | MODEL |

Control style | PC+PLC (GRANDSEED PCBASE WAVE SOLDERING CONTROL SOFEWARE V1.0) |

Conveying motor | 1P AC220V,60W |

Conveying speed | 0 ~ 2000 mm/min |

PCB size | 30 ~ 300 mm (W) |

Flux capacity | 6L |

Pre-heating zone | 1300mm, 3 sections PID controlled individual hot air, zone temperature 250℃ |

Solder pot temperature | 1.KW * 9PCS zone temperature 300℃ |

Solder pot capacity | 240KG |

Solder wave height | 0~12MM |

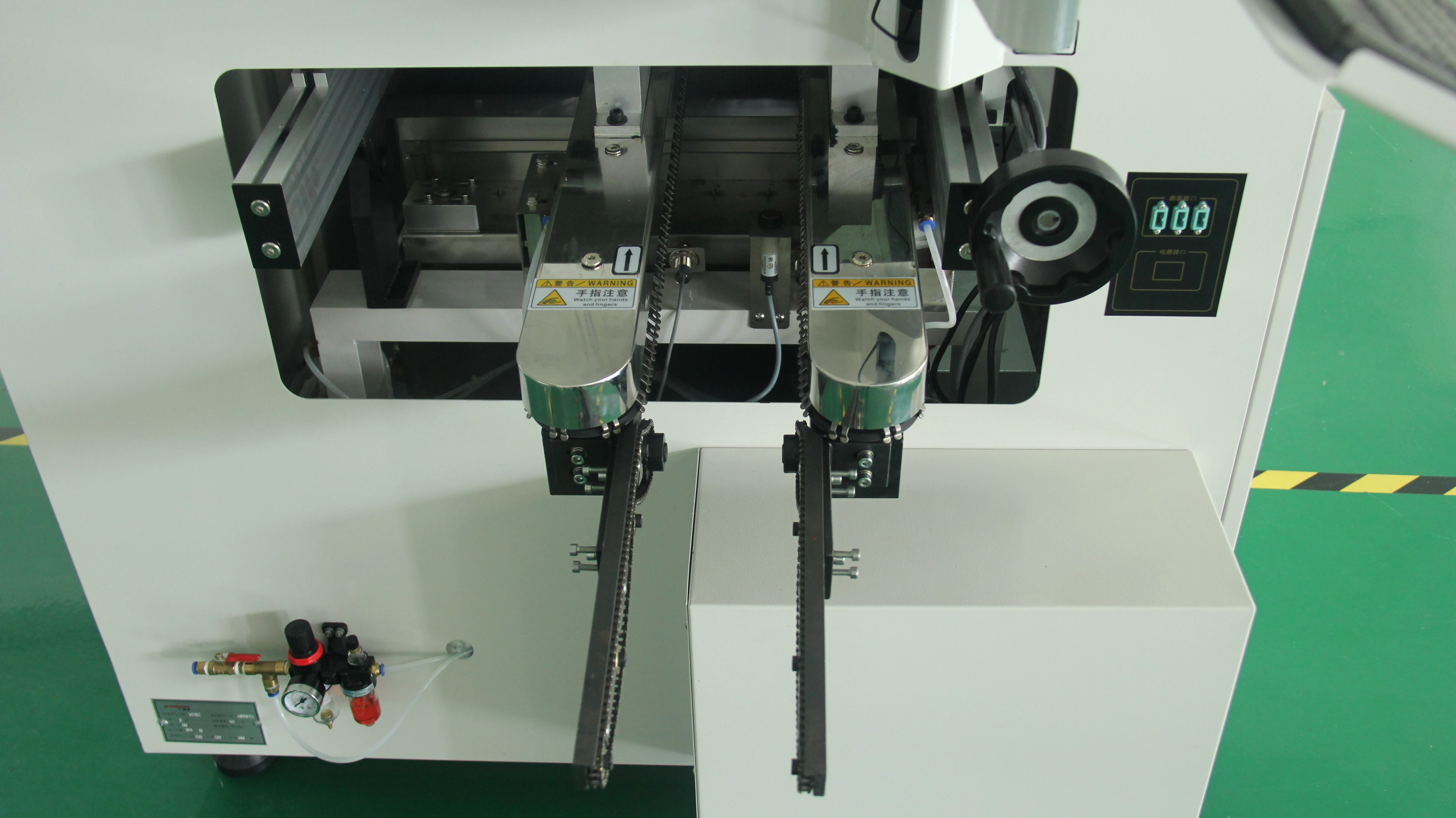

Solder wave motor | 3P AC220V,0.18KW*2PCS |

Finger cleaning pump | 1P AC220V 6W |

Conveying direction | Left→Right |

Soldering angle | 3~6 º |

Flux pressure | 3~5 BAR |

Power supply | AC380V 50HZ |

Normal working power/total power | 5.5KW / 21KW |

Outside dimension | 3560(L)*1200(W)*1650(H) |

Machine dimension | 2700(L)*1200(W)*1650(H) |

Net weight | 900KG |

Features of GSD-WD300C Soldering series

-Automatically start soldering when PCB enters soldering pot zone, and automatically stop when finished.(Patent No.:ZL 2010 2 0056206.3)

-The machine adopts lead-free environmentally friendly independent design, which is convenient and safe in going up and down as well as going in and out, and is easy to clean.

-The machine adopts high grade imported stainless steel, and aluminum silicate for thermal insulation material, when the temperature inside of the solder pot is 270℃, outside temperature≤60℃, which means good heat preservation effect and extremely high security.

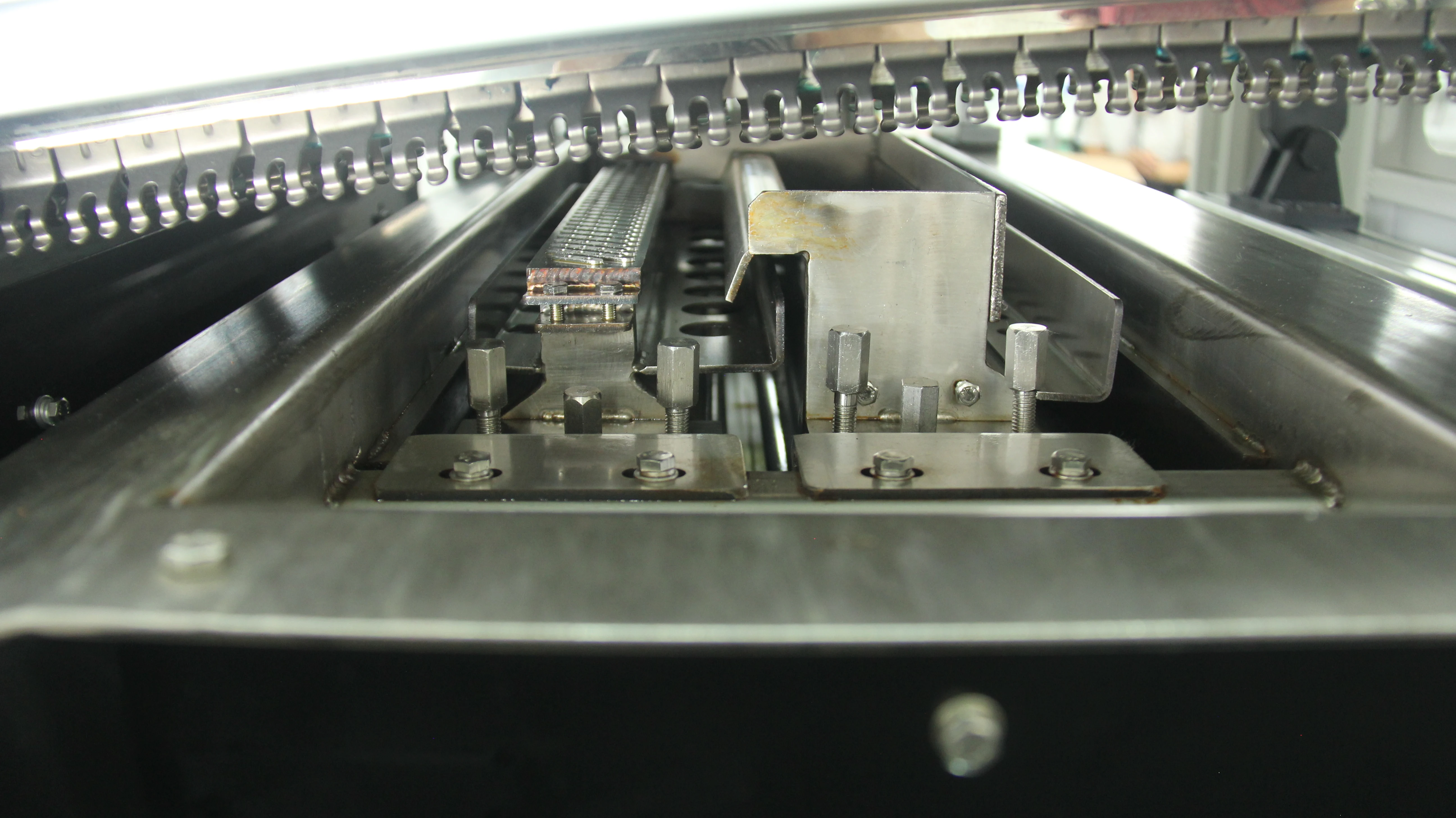

-3MM thick lead-free stainless steel material, which is high temperature and corrosion resistance, and adapts to lead-free technology. Its lifetime is long, standard configuration is one piece of pot liner.

-The solder machine adopts five-surfaces heating method, qiuck in heating up, designs aotumatic on/off time, the heating-up time is 70 minutes for production.

-The solder machihe adopts imported high-temperature motor with stepless frequency conversion control and independent control, stable peak performance.

-Heating of the machine adopts high speed PID external heat two-phase independent control, which is quick in heating, and solved the shortage of the solder machine.

-The spray nozzle of solder pot is adjustable according to the PCB size, which can reducce the area of invalid soldering zone, make sure to minimum the area between soldering and the air, so that greatly reduced the oxidation rate of soldering. There should be some deviation due to the difference of the tin slag from solder bar, it suits to Sn/Ag/Cu,Sn/Zn,Sn/Cu different kinds of lead-free materials,

the oxidation rate of tin slag is 0.8 -2.0KG/8hrs according to the PCB size.

-The machine adds drained cell and anti-static cover, to reduce the black powder and bean-curd dregs of oxide.

-The design is reasonable, tin slag can be collected automaticlly, which makes it easy, convenient and safe to clean the solder pot, no need to fish out the tin slag everyday, just need to clean it once a week or longer accoridng to the actual situation. The tradditional wave soldering's oxidation rate of tin slag is 3-5KG/8 hours,if the reformed solder can save at least 3kg of tin everyday, a month save:118 RMB*3KG*22(DAYS)=7788RMB(if based on SnGu0.7)or 76*3KG*22(DAYS)=5016RMB(if based on 6337Sn),which means it can save the price for one unit of wave soldering a year.

-Fully automatic computer control, Windows XP interface operation amd dynamic monitoring, Grandseed independent research and development PCBASE wave soldering control software V1.0system,significantly increased the work efficiency and decreased the production cost.

- The machine adopts black box memory function, which can call out the production management record at any tome, so as to increase the work efficiency.

- Fully automatic transportation power system, stepless frequency speed adjustment and self-synchronous board entry, PCB board enters the spray system automaticlly.

- the machine provides on-line UPS with power-off protection function, make sure PCB board normal exit without any damage when power-off happened.

Shenzhen Grandseed Technology Development Co., Ltd founded in 2011, which focus on serving the lighting and display industry, our main products are reflow oven, wave soldering, pick and place machine and solder paste printer. We also have five series of main intelligent production line: lighting intelligent production line, Mini LED intelligent production line, flexible light strip intelligent production line, surface mount intelligent production line, robot flexible production line. It owns Anhui Grandseed automation Equipment and Shenzhen Songle intelligent equipment, which all are national high-tech enterprice.

* customization service according to specifications

* 7*24 Hours on line Service

* Professional Technology Team

* Considerate training service

Our advantages:

Production advantages: mass production,assembly line work

Management advantages: simplification of procedures, standard operation

Procurement Advantages: all the accessories supplied by the manufactures directly.

Delivery advantages :supply with stock

Durability advantages: free warranty for one year, three years free of labor costs, maintenance of life;

Service advantages: quickly response, on call 24 hours a day

Certificates

We Recommend

New Arrivals

New products from manufacturers at wholesale prices