Insulated glass system materials Insulating glass Low thermal conductivity butyl spacer

- Category: >>>

- Supplier: Langfang Hong Tianyang Insulating Glass Material Co. Ltd.

Share on (1601072210011):

Product Overview

Description

Insulated glass system materials

Specifications and models] 6mm~16mm

[Color] Mainly black (color can be customized)

[Main purpose] Insulating glass is most commonly used in construction.

【Comply with standards】GB/T11944-2012

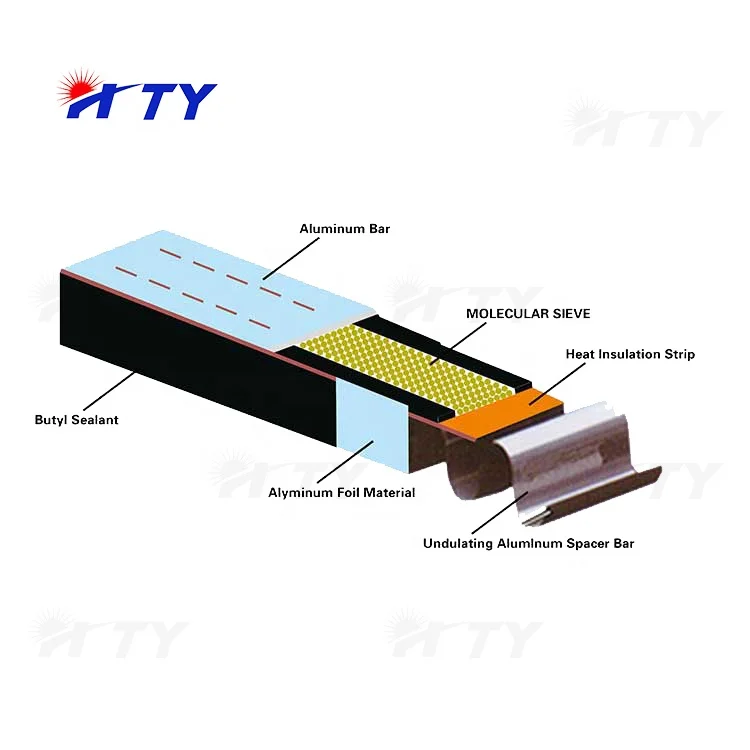

A new insulating glass sealing material was developed based on the original butyl spacer, optimized and improved by integrating various insulating glass sealing forms. Its operating performance, cost investment and sealing reliability are superior to traditional insulating glass sealing materials. Glass sealed form.

【Features】

1. Good sealing: the application of imported butyl rubber makes the sealing better;

2. Better water vapor barrier: The extra-long water vapor barrier makes it difficult for water vapor to enter;

3. Higher production efficiency: no angle insertion is required, the strips can be bent at will, and special-shaped insulating glass of various shapes can be processed (angle insertion is the weakest link in the production process of traditional insulating glass);

4. Good air tightness: The polymer adhesive and tackifier ensure excellent sealing, and the design of the central aluminum strip completely blocks the penetration of water vapor;

5. High temperature resistance: Polymer tackifier improves the high temperature and high humidity resistance of insulating glass;

6. Low temperature resistance: The traditional thermal composite molecular sieve part is extracted from the butyl rubber, and the molecular sieves are concentrated on the inside according to the usage standards to ensure that the insulating glass does not condensate at -50°C; the 3A molecular sieve only absorbs water vapor to make the drying more durable. ;

7. Anti-aging: polymer raw materials, anti-aging agents, ultraviolet absorbers, and shielding agents can effectively resist the erosion of harsh environments;

8. Appearance: The appearance is more beautiful, and the colorful form better caters to the market demand and provides more choices for customers.

【How to use and precautions】

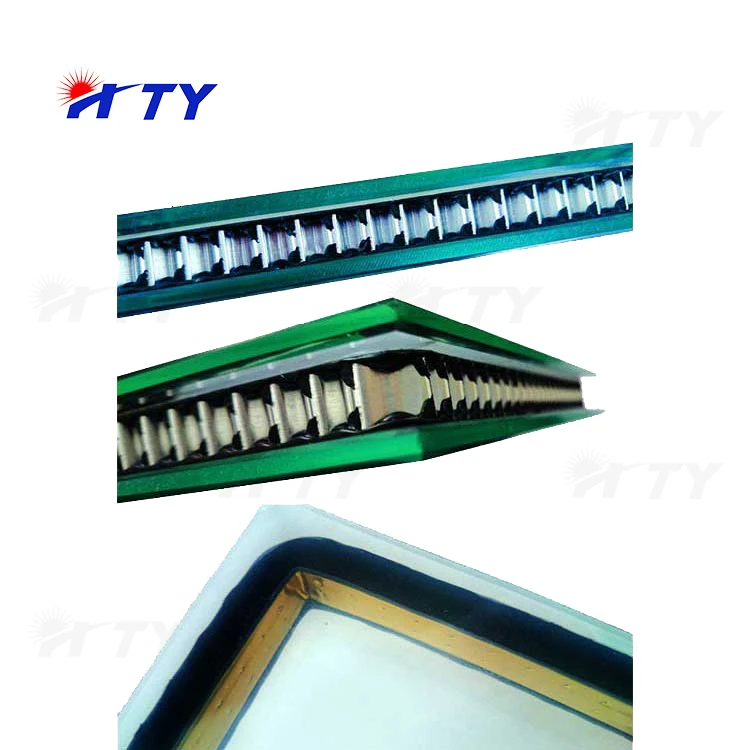

1. After the glass has been cleaned and dried with a cleaning machine (no oil stains or water stains), paste a spacer strip on one corner of one piece of glass, straighten the spacer strip, keep a distance of 2.5mm-3mm from the edge of the glass, and then remove the spacer strip from the edge of the glass. Wrap the spacer around the edge and install sealing tape at the interface. Reserve a 2mm-3mm gap at the sealing area and leave about 20mm more for the joint. Insert the sealing tape into the gap, then press the joint tightly with the sealing tape and pinch the joint tightly;

2. Place another piece of glass on top of the pasted spacer glass. The two pieces of glass must be aligned and level with each other;

3. Feed the insulating glass pasted together into the hot press. The hot pressing temperature is controlled between 110-140℃, and the outlet temperature is controlled between 50-60℃;

4. The two-component silicone sealant can be applied normally according to the structural requirements, and the insulating glass is now completed;

6. The sealing of this product must be carried out according to the butyl spacer sealing operation diagram, otherwise it may cause air leakage in the seal.

[Color] Mainly black (color can be customized)

[Main purpose] Insulating glass is most commonly used in construction.

【Comply with standards】GB/T11944-2012

A new insulating glass sealing material was developed based on the original butyl spacer, optimized and improved by integrating various insulating glass sealing forms. Its operating performance, cost investment and sealing reliability are superior to traditional insulating glass sealing materials. Glass sealed form.

【Features】

1. Good sealing: the application of imported butyl rubber makes the sealing better;

2. Better water vapor barrier: The extra-long water vapor barrier makes it difficult for water vapor to enter;

3. Higher production efficiency: no angle insertion is required, the strips can be bent at will, and special-shaped insulating glass of various shapes can be processed (angle insertion is the weakest link in the production process of traditional insulating glass);

4. Good air tightness: The polymer adhesive and tackifier ensure excellent sealing, and the design of the central aluminum strip completely blocks the penetration of water vapor;

5. High temperature resistance: Polymer tackifier improves the high temperature and high humidity resistance of insulating glass;

6. Low temperature resistance: The traditional thermal composite molecular sieve part is extracted from the butyl rubber, and the molecular sieves are concentrated on the inside according to the usage standards to ensure that the insulating glass does not condensate at -50°C; the 3A molecular sieve only absorbs water vapor to make the drying more durable. ;

7. Anti-aging: polymer raw materials, anti-aging agents, ultraviolet absorbers, and shielding agents can effectively resist the erosion of harsh environments;

8. Appearance: The appearance is more beautiful, and the colorful form better caters to the market demand and provides more choices for customers.

【How to use and precautions】

1. After the glass has been cleaned and dried with a cleaning machine (no oil stains or water stains), paste a spacer strip on one corner of one piece of glass, straighten the spacer strip, keep a distance of 2.5mm-3mm from the edge of the glass, and then remove the spacer strip from the edge of the glass. Wrap the spacer around the edge and install sealing tape at the interface. Reserve a 2mm-3mm gap at the sealing area and leave about 20mm more for the joint. Insert the sealing tape into the gap, then press the joint tightly with the sealing tape and pinch the joint tightly;

2. Place another piece of glass on top of the pasted spacer glass. The two pieces of glass must be aligned and level with each other;

3. Feed the insulating glass pasted together into the hot press. The hot pressing temperature is controlled between 110-140℃, and the outlet temperature is controlled between 50-60℃;

4. The two-component silicone sealant can be applied normally according to the structural requirements, and the insulating glass is now completed;

6. The sealing of this product must be carried out according to the butyl spacer sealing operation diagram, otherwise it may cause air leakage in the seal.

name | color | size |

butyl spacer | silver | 6mm~16mm |

butyl spacer | gold | 6mm~16mm |

butyl spacer | black | 6mm~16mm |

butyl spacer | grey | 6mm~16mm |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices