Ulite China Plastic Power Banks Mold Factory Plastic Injection Molding Parts Mold Manufacture Service

- Category: >>>

- Supplier: Shenzhen Ulite Precision Tech LimitedShenzhen Limited

Share on (1601074668899):

Product Overview

Description

Our Factory

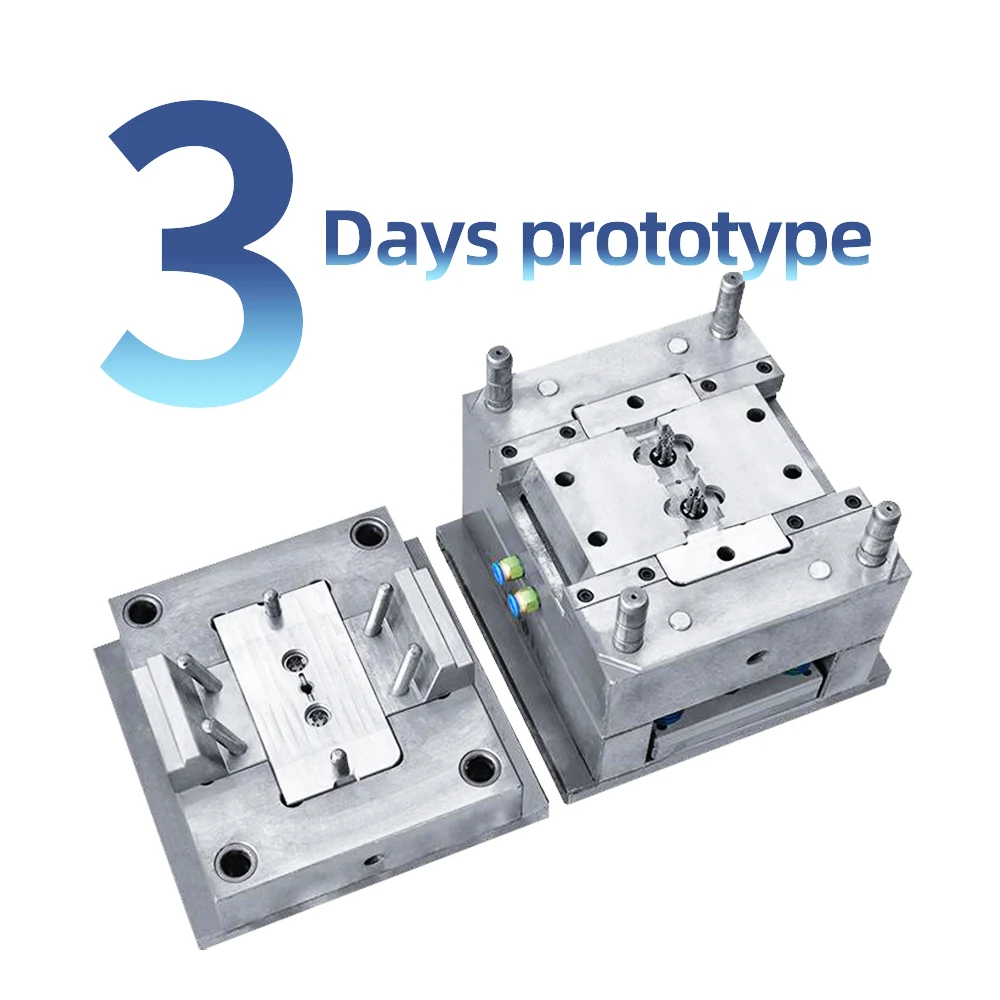

One-stop Injection Mold Manufacturing and Plastic Parts Production Assembly

How to get a quote quickly :

1. Prepare pictures or 3D drawings, 2. Materials for the required products,

3. Quantity of each order and estimate the annual demand.

We will quickly provide you with professional advice to save mold costs and maintain high quality.

Mold Description

Mould Details -

Name | Plastic Injecition Mold |

Mould core | P20,NAK80,SKD11,S316,S50C,S45C,718H,718 or customers' appointed |

Mould base | LKM, HASCO, DME or upon customer's requirement |

Type of plastic mold | 3-plate mold,2-plate mold |

Cavity | Single/Multi 1*1,1+1,1*2,1+1+1,etc |

Mode Gate | Fan gate,Sub gate,Pin Point gate,Valve |

Ejection system | Stripper plate,Lifter,Push Bar,Ejection Pin etc |

Runner | Hot/cold type |

Plastic material | HDPE, PP, nylon, PEEK, LDPE, ABS, styrene, acrylic, acetal, PE, PTFE, PEI, and PES |

Mould life | 300,000-1,000,000 shots |

Lead time | 15-35days after deposit received |

Specification | Follow the 3D final drawing |

Packaging details | covering with film for anti rust and packed with wooden Case |

Parts Production Details -

Product Material | ABS,AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

MOQ | 500 PCS |

Packaging details | Carton box or wooden Case upon product weight and customer's requirements. |

Shipping | By sea or by air as customer requirement |

Export Country | Janpan,Europe,USA,Mexico,Australia,Middle East,Korea,Asia etc |

Typical Used For | Housings, containers, caps, fittings,including as below Power-tool housing, Disposable razors, Electrical Switches,Crates/Recycling boxes Automotive dash boards,Television Cabinets,Drug Inhalation Units,Automotive bumpers, Wheelie bins ,Syringes,Telephone handsets ,Washing-up bowls,DVDs, Bottle Lids/closures,Battery Casings |

Range of markets | industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, healthcare, telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, gears, RFID tags, electronics, and fasteners. |

Product packaging

Mold Export

Firstly assembling and clearing mold well, and then paint anti-rust fog or grease on mold, then cover with thin film and place it into a stable wooden case.

Product Shipping

Firstly,to wrap each part up with semi-transparent thin foam and put it into plastic bag, the second step is place them into

cartons with thin sponge plates to prevent scratches.

Firstly assembling and clearing mold well, and then paint anti-rust fog or grease on mold, then cover with thin film and place it into a stable wooden case.

Product Shipping

Firstly,to wrap each part up with semi-transparent thin foam and put it into plastic bag, the second step is place them into

cartons with thin sponge plates to prevent scratches.

FAQ

Q1: Is injection moulding easy?

A1: Plastic injection moulding is a complex manufacturing process commonly used to create plastic components. The ability of injection moulding to produce thousands of complex parts quickly makes it the perfect process for the mass production of plastic components.

Q2: What are the basics of molding?

A2: The basics of plastic injection molding process includes creating the product design, making a tooling a mold to fit the product design, melting the plastic resin pellets, and using pressure to inject the melted pellets into the mold

A3: Yes, We can provide one-stop service for mold making and plastic parts production and assembly

Q4: How much does it cost to injection mold plastic?

A4.: A small and simple single-cavity plastic injection mold usually costs between $1,000 and $5,000. Very large or complex molds may cost as much as $80,000 or more. On average, a typical mold that produces a relatively simple part small enough to hold in your hand costs around $12,000.

Q5. Why does injection molding cost so much?

A5. Injection molding includes high-precision molds whose design is time-consuming and labor-intensive. After having the 3D structure data of the product, it still needs to be fully analyzed sub-molded, and split 2D parts drawing. The choice of mold material has a great impact on the cost.

Q6. What is tool in injection molding?

A6. The mold is often referred to as tooling. Mold and tooling are relatively interchangeable terms for the metal mold at the heart of the injection molding process. Mold tooling may also be used to describe the process of machining the mold out of a block of metal.

Q7: What is the most common material for injection molding?

A7: These are the most common plastic materials for injection molding: acrylic (PMMA) acrylonitrile butadiene styrene (ABS) nylon(polyamide, PA)

We Recommend

New Arrivals

New products from manufacturers at wholesale prices