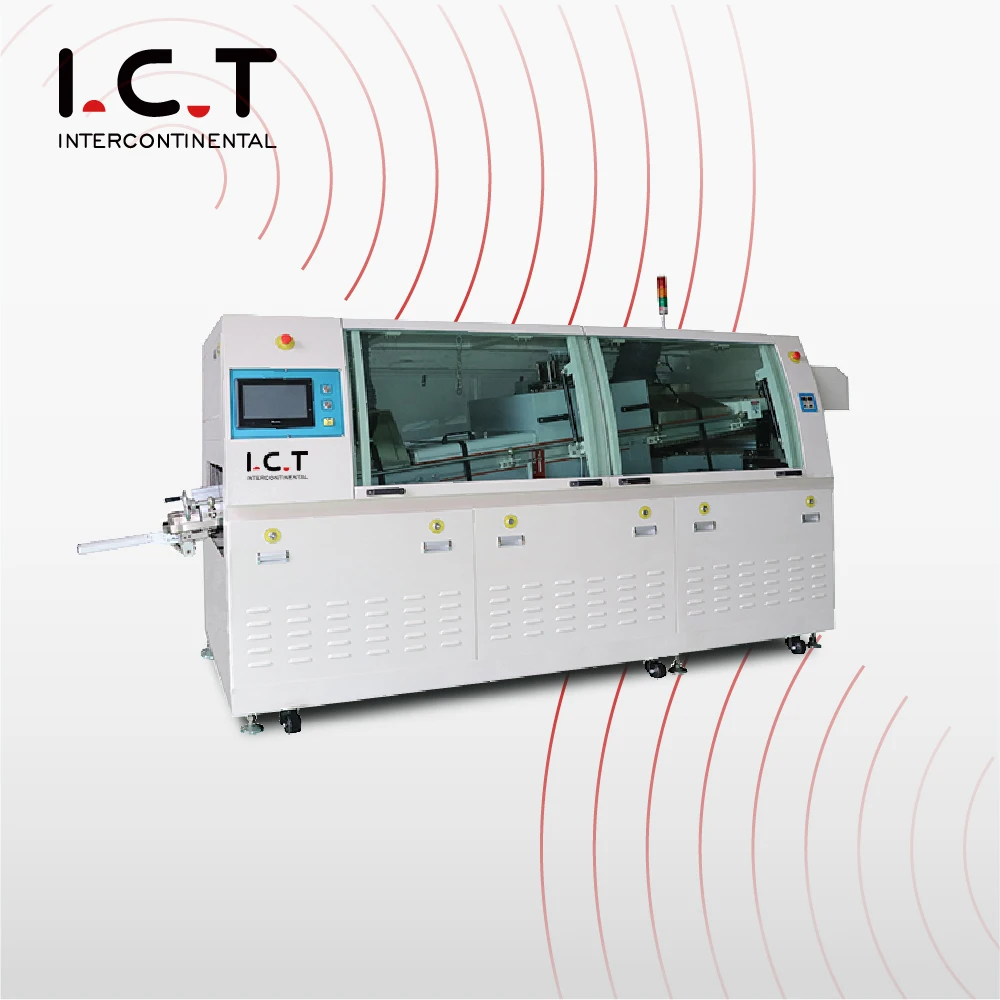

GRANDSEED best quality Automatic SMT Wave soldering GSD WD350CE DIP Wave Soldering Machine

- Category: >>>

- Supplier: Shenzhen Grandseed Technology Development Co. Ltd.

Share on (1601074883502):

Product Overview

Description

GSD-WD350CE SPECIFICATIONS | |

ITEMS | MODEL |

Control style | PC+PLC ( GRANDSEED PCBASE WAVE SOLDERING CONTROL SOFEWARE V1.0) |

Conveying motor | 1P AC220V,60W |

Conveying speed | 0~2000mm/min |

PCB size | 30~350mm(W) |

Pre-heating zone | 1800mm 3 sections PID controlled individual hot air, zone temperature ~250℃ |

Solder pot temperature | 1KW * 12PCS zone temperature~300℃ |

Solder pot capacity | ≈480KG |

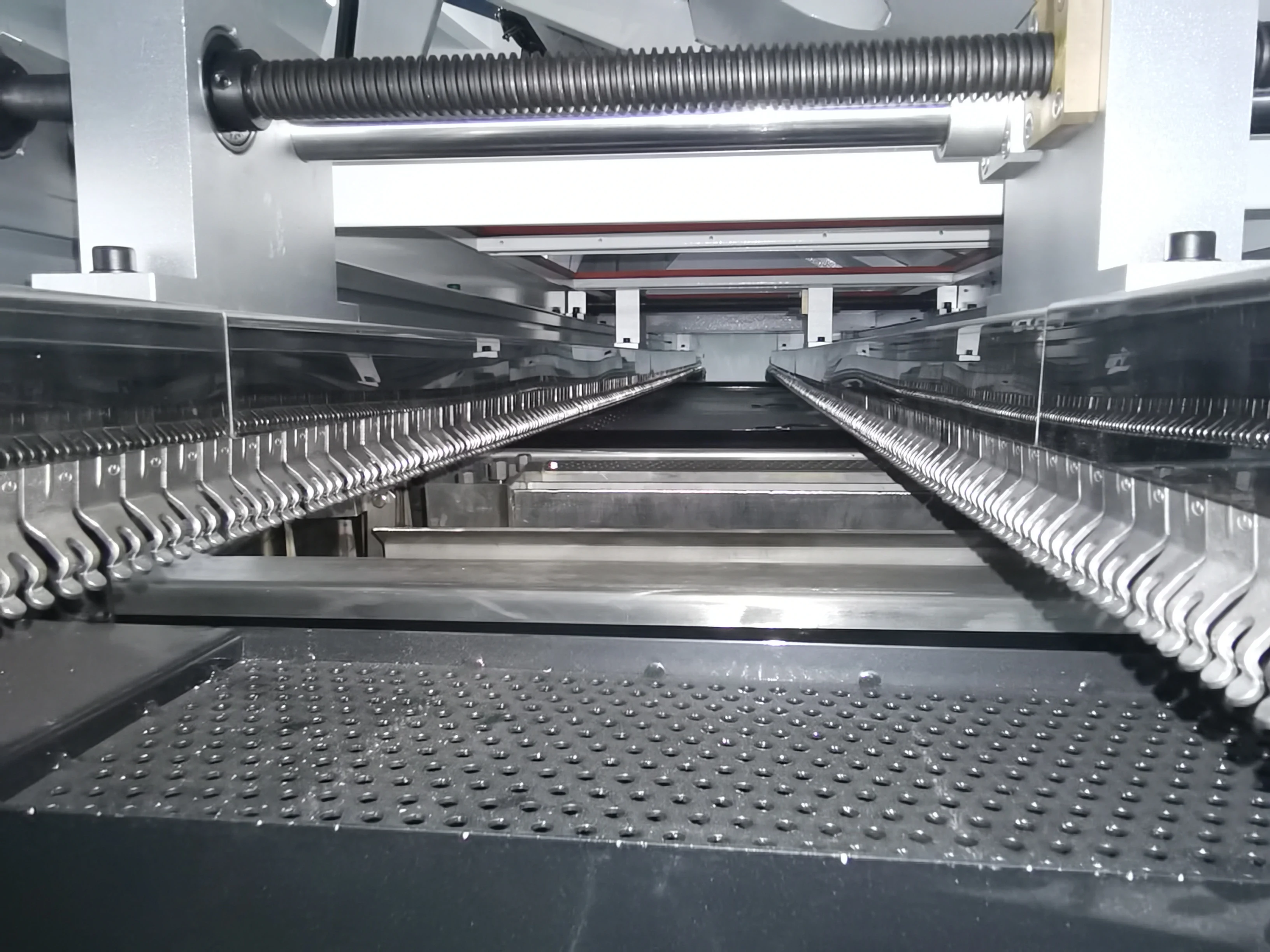

Solder wave height | 0~12MM |

Solder wave motor | 3P AC220V,0.18KW * 2PCS |

Finger cleaning pump | 1P AC220V 6W |

Conveying direction | Left→right |

Soldering angle | 3 ~ 6 º |

Flux pressure | 3 ~ 5 BAR |

Power supply | AC380V 50HZ |

Normal working power/total power | 8KW/32KW |

Outside dimension | 4535(L)*1600(W)*1700(H)MM |

Machine dimension | 3800(L)*1600(W)*1700(H)MM |

Net weight | 1800KG |

Features of GSD-WD350CE Soldering series

1.The PCB board enters and automatically starts soldering. After soldering is completed, the wave peak automatically stops. (Patent No. ZL 2010 2 0056206.3)

2.The solder pot is independently designed for lead-free environmental protection, making it convenient for lifting and entry/exit, and safe, and easy to clean,

3. the solder pot is made of high quality ductile iron+surface enamel treatment and insulated with aluminum silicate insulation material. When the temperature inside is 270 ℃ and the temperature outside the furnace is ≤ 60 ℃, the insulation effect is good and the safety is high.

4. Fast heating and automatic on/off time design. The tin furnace can be produced within 120 minutes of heating time.

5. The solder pot adopts imported high-temperature motors, stepless frequency conversion speed regulation, independent control, and stable peak performance;

6. The heating of the solder pot adopts a high-speed PID external heating two-stage independent control, which heats up quickly and solves the problem of tin explosion in the tin furnace;

7. The tin furnace nozzle can be adjusted according to the width of the PCB board you want to pass through, reducing the area of ineffective welding and keeping the contact area between solder and air small, greatly reducing the oxidation of solder. The tin bars contain different impurities, and there may be deviations in the tin slag. Suitable for various lead-free solder materials such as Sn/Ag/Cu, Sn/Zn, and Sn/Cu, with a tin slag oxidation rate of 0.8-2.0 KG every 8 hours (depending on the size of the PCB board)

8. The machine Increases diversion channels and anti oxidation sleeves to reduce black powder and tofu residue like oxides.

9. The design is reasonable, and the tin slag is automatically collected. Cleaning the tin furnace is simple, convenient, and safe, without the need to scoop up the tin slag every day. It can be cleaned once a week or longer according to the situation.

Shenzhen Grandseed Technology Development Co., Ltd founded in 2011, which focus on serving the lighting and display industry, our main products are reflow oven, wave soldering, pick and place machine and solder paste printer. We also have five series of main intelligent production line: lighting intelligent production line, Mini LED intelligent production line, flexible light strip intelligent production line, surface mount intelligent production line, robot flexible production line. It owns Anhui Grandseed automation Equipment and Shenzhen Songle intelligent equipment, which all are national high-tech enterprice.

* customization service according to specifications

* 7*24 Hours on line Service

* Professional Technology Team

* Considerate training service

Our advantages:

Production advantages: mass production,assembly line work

Management advantages: simplification of procedures, standard operation

Procurement Advantages: all the accessories supplied by the manufactures directly.

Delivery advantages :supply with stock

Durability advantages: free warranty for one year, three years free of labor costs, maintenance of life;

Service advantages: quickly response, on call 24 hours a day

Certificates

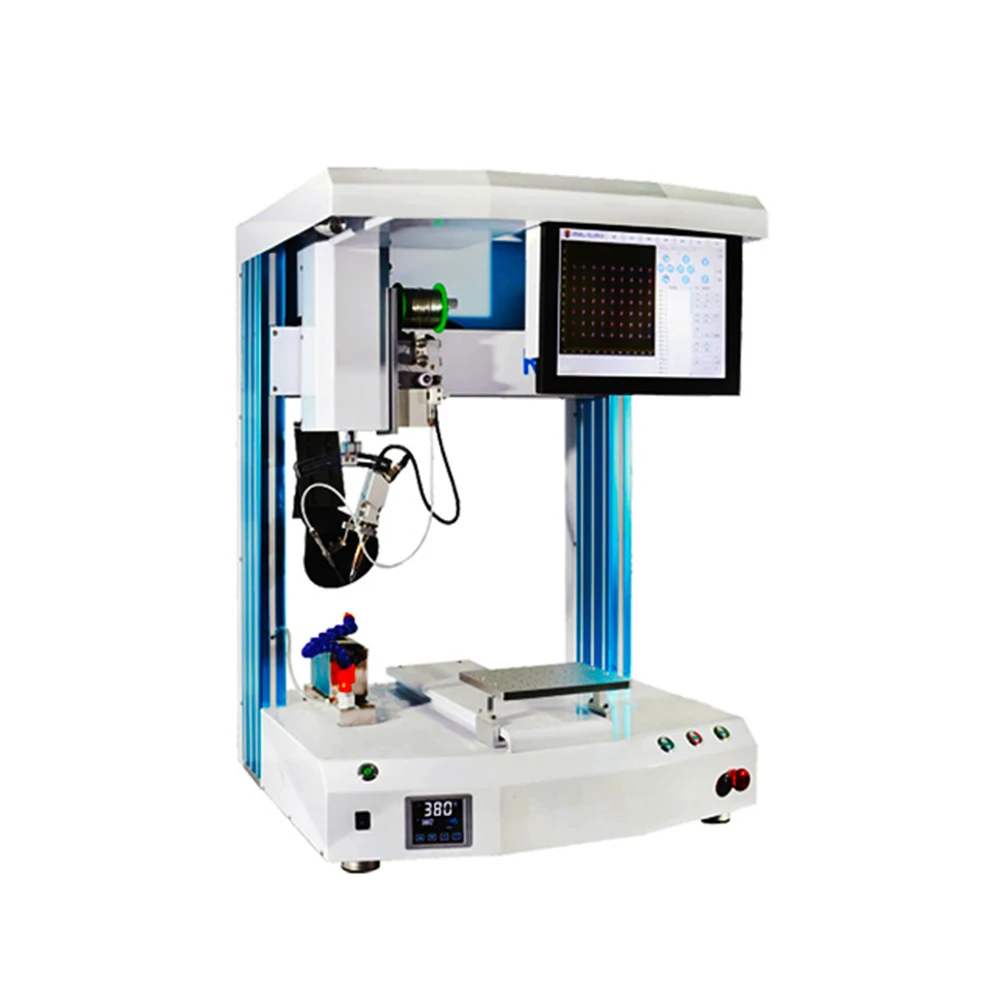

We Recommend

New Arrivals

New products from manufacturers at wholesale prices