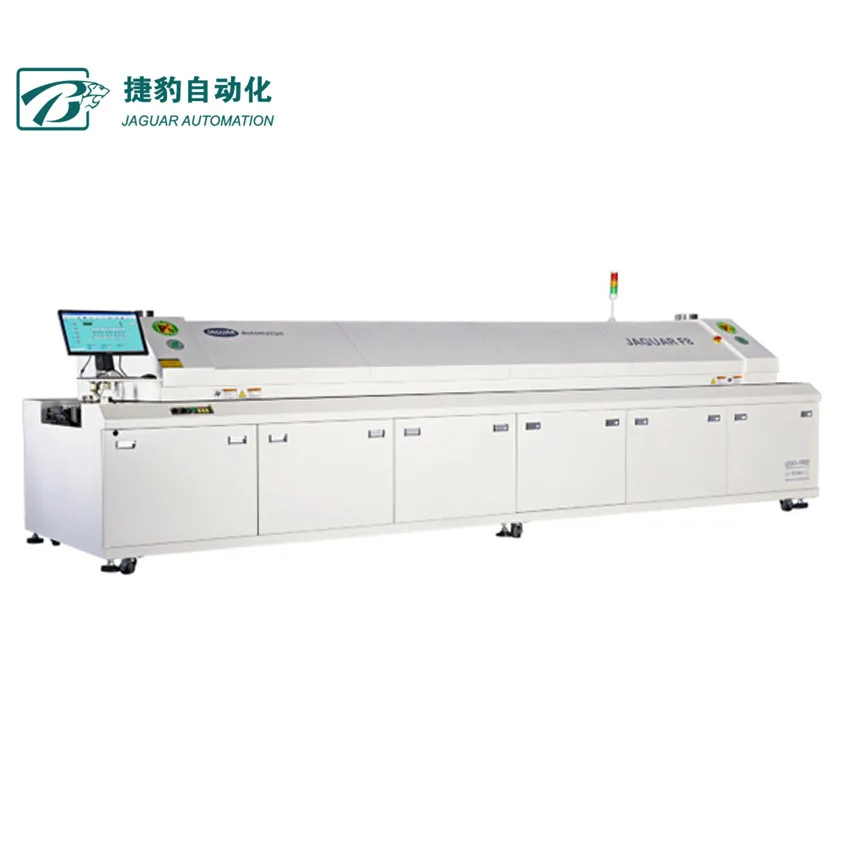

GRANDSEED Factory Price High quality Professional SMT Reflow Oven with Factory Price LED Free GSD L10 Large Soldering

- Category: >>>

- Supplier: Shenzhen Grandseed Technology Development Co. Ltd.

Share on (1601084684623):

Product Overview

Description

-To extend the service life of the motor, our company's technical personnel specialize in design; Enable internal cooling circulation convection to lower the temperature around the motor to around 38 ℃;

-High quality, high-temperature, and high-speed motors operate smoothly with minimal vibration and low noi

-Professional wind turbine design, stable wind speed, effectively preventing the uniformity of wind when PCB boards are heated, achieving the highest repeated heating;

-Each temperature zone adopts forced independent circulation, independent PID control, and independent heating mode from top to bottom, ensuring accurate and uniform furnace chamber temperature and large heat capacity; Leading heating method solves the problem of dead corners during reflow soldering. Suitable for soldering electrical components such as CSP, BGA, 0201CHIP, etc;

-An online UPS equipped with power outage protection function ensures that the PCB board can output normally without damage after power outage.

- An independently controlled cooling system made of stainless steel, with upper and lower cooling convection. The cooled curve is mirrored with the welding temperature curve, fully complying with SMT international certification standards.

-The insulation layer is made of high-quality aluminum silicate insulation material, with a multi-layer insulation furnace design. The surface temperature of the outer shell of the furnace is about 5 degrees higher than the ambient temperature, effectively reducing the working environment temperature. The insulation effect is good, and the temperature rises quickly, from room temperature to working temperature ≤ 20 minutes; Special furnace design, with the lowest power consumption in the industry;

Control system features:

-Windows operating system, with a Chinese and English interface, easy to operate and learn; Two control methods, computer control and emergency manual control, with safety protection function;

-PC and PLC (microcontroller) adopts PC and PP protocols, ensuring stable operation and preventing crashes;

-Automatic monitoring, displaying the working status of the equipment, facilitating real-time monitoring of the equipment;

Structure features:

-The skeleton is made of 40 × 80 flat pipes, and the steel frame structure is reasonable and not easy to deform. The welding adopts secondary protection welding, which is stable and solid. The outer garment is made of T: 2.0 national standard Ansteel cold-rolled plate, processed by CNC machine tool, and has a front and rear door pneumatic structure The design of the upper cover is reasonable, and it can be easily opened with a force of 3KG. When opened, it forms a dovetail shape, making the inspection and maintenance of the motor more convenient and simple. Enable safety and save effort. The overall design is reasonable, efficient, energy-saving, safe, and environmentally friendly;

-The furnace opening is more convenient, with fully automatic electric lifting and safety rod support protection, ensuring safety and reliability; The heating module adopts a split type combination, which has stable performance, convenient disassembly and maintenance, and more convenient replacement of heating wires; Internally, all are made of imported stainless steel plates, CNC processed, with precise dimensions and fine workmanship, eliminating defects such as paint peeling and deformation in traditional reflow soldering;

-The reasonable mechanical transmission part is processed by precision machine tools, fully automatic width adjustment, dedicated guide rails, durable and non deformable, and adopts high-temperature resistant chains with automatic refueling function, which can move freely under high temperatures of 350 ℃. The transmission method of PCB board adopts stepless frequency conversion and synchronous network chain, with excellent stability; There will be no adverse effects of traditional reflow soldering;

-The unique automatic flux recovery system filters or recovers most of the exhaust gas and returns it to the furnace, reducing heat loss while making flux recovery more thorough and maintaining furnace cleanliness for a long time.

Shenzhen Grandseed Technology Development Co., Ltd founded in 2011, which focus on serving the lighting and display industry, our main products are reflow oven, wave soldering, pick and place machine and solder paste printer. We also have five series of main intelligent production line: lighting intelligent production line, Mini LED intelligent production line, flexible light strip intelligent production line, surface mount intelligent production line, robot flexible production line. It owns Anhui Grandseed automation Equipment and Shenzhen Songle intelligent equipment, which all are national high-tech enterprice.

* customization service according to specifications

* 7*24 Hours on line Service

* Professional Technology Team

* Considerate training service

Our advantages:

Production advantages: mass production,assembly line work

Management advantages: simplification of procedures, standard operation

Procurement Advantages: all the accessories supplied by the manufactures directly.

Delivery advantages :supply with stock

Durability advantages: free warranty for one year, three years free of labor costs, maintenance of life;

Service advantages: quickly response, on call 24 hours a day

Certificates

We Recommend

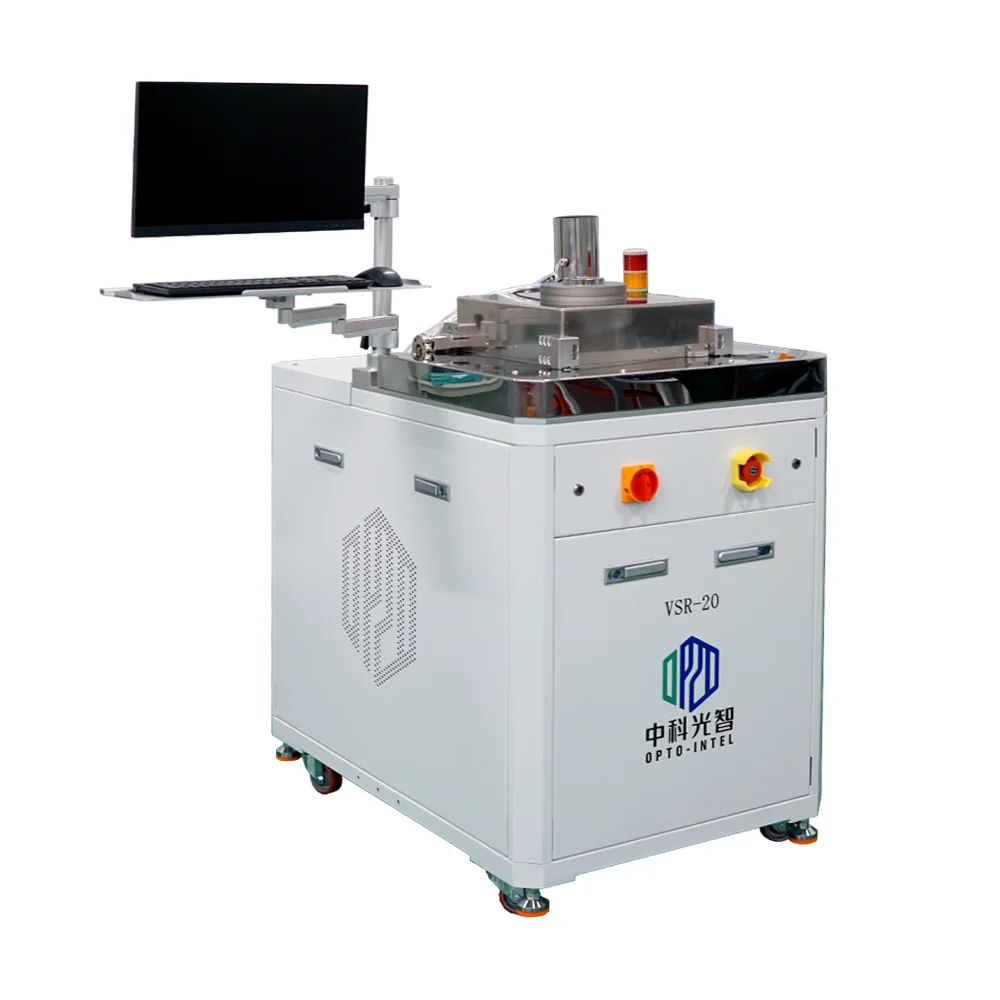

Power Module Device Vacuum Reflow Oven KD-V10N China Factory Vacuum Soldering Oven

Hanwha SM482 Plus Pick and Place Machine

Vacuum Soldering Furnace Formic Acid Vacuum Soldering System IGBT Module Packaging Oven

New Arrivals

New products from manufacturers at wholesale prices