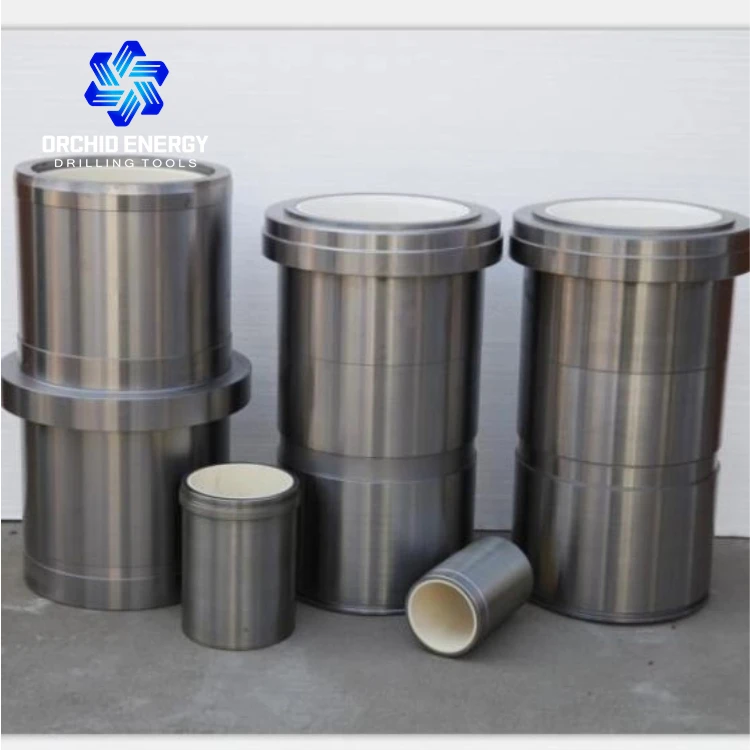

API Gardner Denver Mud Pump Parts Ceramic Bimetal Cylinder liner 140mm Cylinder Bushing

- Category: >>>

- Supplier: Orchid Energy Co. Ltd.

Share on (1601095347746):

Product Overview

Description

Products Description

The mud pump is the "heart" of the oilfield drilling system, and the cylinder liner is an important and easily worn component of the fluid end module of the mud pump. Therefore, the lifespan of the cylinder liner directly affects the mud pump. The working surface of the cylinder liner is in contact with high temperature and high-pressure gas, and there are piston rings that perform high-speed reciprocating motion on its surface. This determines that the cylinder liner not only needs sufficient strength and rigidity, but also must be resistant to high temperature, corrosion, and wear.

Zirconia Ceramic Cylinder Liner

The hard and wear-resistant zirconia ceramic cylinder liner has strong resistance to acid and alkali corrosion, making it suitable as a cylinder body material for mud pumps. It is suitable for drilling and production environments with deep oil reservoirs and harsh geological structures, as well as offshore oil and gas development.

Specification

No. | Types of liner | Introduction | Advantage |

1 | Ceramic Liner | Using advanced toughened zirconia material, its fracture toughness value can reach 10-15Mpa, bending strength is 600-800Mpa, and its wear resistance and corrosion resistance are excellent, suitable for various harsh well conditions | 1. High strength, wear-resistant, corrosion-resistant, high-pressure resistant, and high-temperature resistant; 2. Low maintenance and labor costs; 3. Longer service life; 4. Reduce piston wear and loss; |

2 | Bimetal liner | Composed of a forged wear-resistant outer sleeve and a high chromium wear-resistant and corrosion-resistant inner sleeve. After inner sleeve treatment, the hardness can be increased by HRC64 | 1. High hardness and corrosion resistance; 2.No deformation, good surface smoothness; |

3 | Monometallic liner | The quenching thickness of the carbon layer in the inner hole of a monometallic cylinder liner can reach 1.5~1.8 mm, and the hardness can reach 58~60HRC | 1. High hardness; 2. High surface smoothness; |

Size of Liner (Metric) | 90mm / 100mm / 110mm / 120mm / 130mm / 140mm / 150mm / 160mm / 170mm / 180mm |

Size of Liner (Imperial) | 4” / 4 1/2” / 5” 5 1/2” / 6” 6 1/4” / 6 1/2” / 6 3/4” / 7” / 7 1/2” / 8” |

The types of mud pumps that Orchid Energy's cylinder liners can adapt | Emsco: F-350 / F-500 / F-650/ F-800 / F-1000/ F-1300 / F-1600 |

Gardner Denver: TEE / PAH / PZ-7/ PZ-8 / PZ-9 / PZ-10 / PZ-11 | |

Ideco: T-500 / T-800 / T-1000 / T-1300 / T-1600 | |

NOV: 7-P-50 / 8-P-80 / 9-P-100/ 10-P-130 / 12-P-160 / 14-P-220 | |

Oilwell: A-850-PT / A-1100-PT / A-1400-PT / A-1700-PT | |

Bomco: F-500 / F-800 / F-1000/ F-1300 / F-1600/ F-2200HL | |

Wirth: TPK 1000 / TPK 1300 / TPK 1600/ TPK 2000 / TPK 2200 | |

Aplex: SC -170L / SC-230 / SC-300 | |

Russia Pump: UNB600 / UNBT950 / UNBT950 / UNBT1180 |

Recommended for You

Packaging and Delivery

Factory & Workshop

Company Profile

Introduction

Orchid Energy Ltd. is a factory manufacturer of drilling tools with over 20 years' experience. Our core products include drilling motors, stabilizers, drill collars, mud pump and spare parts, as well as key components such as kellys, tubulars, drilling jars, fishing tools, and bearings according to customers' needs.

Orchid Energy has not only standard-sized products but also supports the customized production of products according to customers' requirements. In the two aspects of price and quality, Orchid Energy do not hesitate to choose to adhere to the premise of ensuring product quality, and then as far as possible to suppress the price of the product, because of this, the price of our products may not necessarily be the lowest in the industry, but we firmly believe that the time will help us win more praise from our customers.

Orchid Energy has not only standard-sized products but also supports the customized production of products according to customers' requirements. In the two aspects of price and quality, Orchid Energy do not hesitate to choose to adhere to the premise of ensuring product quality, and then as far as possible to suppress the price of the product, because of this, the price of our products may not necessarily be the lowest in the industry, but we firmly believe that the time will help us win more praise from our customers.

Contact Us

You can contact us through the online chatting of alibaba, meanwhile, other ways are also available as following:

FAQ

Are you a factory manufacturer?

Yes, we are a factory manufacturer with dual production capacity and quality assurance. We have our own technical R&D engineers and production workshops, providing customers with high-quality and affordable tools and equipment related to the petroleum industry.

What's your process for handling my inquiry?

First, we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be requested to do pre-paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 7-15days if we don’t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

How can I pay for the order?

After you confirm our PI, we will request you to pay. T/T, L/C, D/P, Western Union are the most usual ways we are using. We could discuss other payment method convenient for you.

How about your after-sales service?

When you need after-sales service, please contact our sales manager and make it clear, our after-sales support team will be involved into the case until the problem be solved. There are two common types of after-sales requirements:

1) Related to this batch of goods: You have a series of questions about the operation, maintenance, and upkeep of the product, most of which are clearly stated in the product manual. If you still have questions, you can contact our sales manager.

2)Non-relate to this batch of goods: The project cannot proceed normally due to the lack of other software and hardware, which is not caused by our products. We can provide you with all feasible assistance in this process.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices