CNC Bending Machine 60T 2m GP Hydraulic Press Brake Machine for Metal Plate

- Category: >>>

- Supplier: Accurl Cnc Machine(anhui) Manufactory Co. Ltd.

Share on (1601103513681):

Product Overview

Description

Product Description

CNC PRESS BRAKE EURO GENIUS SERIES

ACCURL® EURO-GENIUS Series press brake features an CNC crowning system for improved quality, a servo driven back gauge system for

increased speeds, and 3D capable graphical control unit to simulate bending sequences and collision points.Also has increased

working speeds, stroke, daylight, and pressing capacities of GENIUS Series machines. The future - as a result of rising energy

costs and increasingly cost efficient speed-controlled drives offered on the market, variable-speed solutions are on the advance.

ACCURL® EURO-GENIUS Series press brake features an CNC crowning system for improved quality, a servo driven back gauge system for

increased speeds, and 3D capable graphical control unit to simulate bending sequences and collision points.Also has increased

working speeds, stroke, daylight, and pressing capacities of GENIUS Series machines. The future - as a result of rising energy

costs and increasingly cost efficient speed-controlled drives offered on the market, variable-speed solutions are on the advance.

Details Images

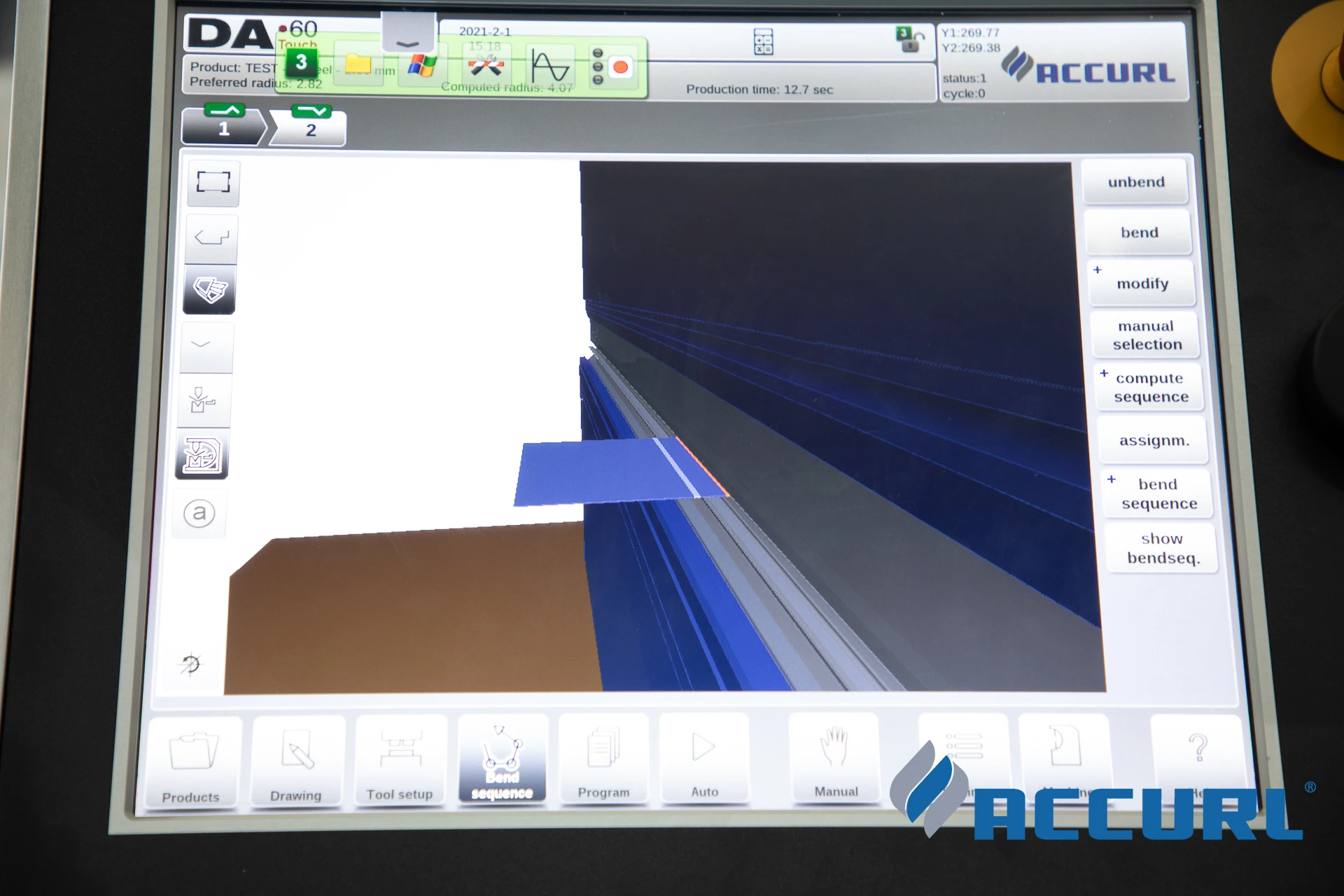

CNC CONTROL SYSTEM

CNC BACKGAUGE

ACCURL press brake are provided are equipped with a backgauge constituted by a solid structure in order to assure the best

repetitiveness and high precision in axes positioning.

repetitiveness and high precision in axes positioning.

BGA | X | R | Z1 | Z2 | X2 |

Stroke(mm) | 750 | 150 | UNDER REQUEST | UNDER REQUEST | 190 |

Speed(mm/s) | 500 | 170 | 2000 | 2000 | 200 |

Precision(mm) | +0,02 | +0,05 | +0,05 | +0,05 | +0,02 |

Type of motor | BRUS HLESS | BRUS HLESS | BRUS HLESS | BRUS HLESS | BRUS HLESS |

Mechanical system | SCREW | SCREW | RACR | RACR | SCREW |

WILA NEW STANDARD CROWANG AND HOLDERS

WILA Crowning systems fully compensate for the deflection in press brakes. This results in a consistent bending angle across the

entire length of the machine. WILA New Standard Crowning Systems utilize a series of patented adjustable wedges known as Wila

Waves.

entire length of the machine. WILA New Standard Crowning Systems utilize a series of patented adjustable wedges known as Wila

Waves.

LAZERSAFE OPTICAL SAFETY GUARDS

Performance without compromise. ACCURLuse LazerSafe LZS-LG-HS guarding system offers a highly effective solution for both operator

safety and machine productivi- ty.Designed for use with Lazer Safe's PCSS A Serice, the Lazersafe is category 4 compliant and

meets the world’s most demanding international safety standards(CE Certified Category 4 Safety Controller with integrated)。

safety and machine productivi- ty.Designed for use with Lazer Safe's PCSS A Serice, the Lazersafe is category 4 compliant and

meets the world’s most demanding international safety standards(CE Certified Category 4 Safety Controller with integrated)。

LASER CHECK ANGLE MEASUREMENT

Laser Check, manufactured by Data M Engineering, is a bend angle measurement and correction system by means of a laser beam. The

device is made of a laser and a camera on both sides of the bending line. Detection is carried out in this way.

device is made of a laser and a camera on both sides of the bending line. Detection is carried out in this way.

CNC FOLLOWER SUPPORTS AP1 + AP2

It basically consists of a pair of sheet supports placed on the front of the machine at the height of the bending line (bottom

tool). Supports are controlled by the CNC, following and supporting the sheet during the bending process.

tool). Supports are controlled by the CNC, following and supporting the sheet during the bending process.

WILA NEW STANDARD AND CLAMPING SYSTEMS

Innovative and super-fast clamping systems for clamping punches to the upper beams of press brakes. The Universal Press Brake

Concept (UPB) makes it possible install New Standard and Clamping Systems on any press brake.

Concept (UPB) makes it possible install New Standard and Clamping Systems on any press brake.

Technological Process

Company Profile

Haco CNC Machine(Anhui) Manufactory Co., LTD. (abbreviation "ACCURL") is a famous manufacturer of metal sheet equipments in world market. Its Brand "ACCURL" has been leading brand for many years in the field of international metal sheet equipments. Our group devote ourselves to product development, production and sales.

Our production base lies in Bowang equipment industrial park, which is "China edge molding machine first town". It's just 30km from our factory to Nanjing Lukou airport, and closed to China Yangtze River Delta economic zone.We own convenient transportation and Customs Clearance.and registered capital is 32 million.

MVD covers a total area of 56,600 square meters. In workshop, we configure advanced vertical and horizontal machining centers. We have 16m larger Floor Boring and Milling Machine these advanced CNC machining equipment and sophisticated detection equipments.

Our main products are: CNC Press Brake, Shears, Hydraulic press, Laser Cutter and CNC rolling machine these sheet metal processing equipments.

We are using advanced technology from German, Japan, and Italy.we can produce large Hydraulic Press and Press Brake more than 16000 ton & 16m.we are with professional R&D team, and we have World-class design and manufacturing capabilities.

We'll be unswervingly based on technological innovation, technology research and development products, Emphasis on product quality and integrity of services.

MVD have Talents in professional field to offer the installation, commissioning, training, after-sales service.Each client will get quality service on time.

We win large market at home and abroad through novel design, excellent quality and perfect after-sales service.

"Technology Innovation, China creation" is MVD's fundamental.

"Customer service, the pursuit of quality is MVD's Philosophy"

"Meet customer requirements, improve the quality continuously" is MVD's tenet.

We'll continue going beyond ourselves.

Create value for clients, and offer better technology, products and service!

Our production base lies in Bowang equipment industrial park, which is "China edge molding machine first town". It's just 30km from our factory to Nanjing Lukou airport, and closed to China Yangtze River Delta economic zone.We own convenient transportation and Customs Clearance.and registered capital is 32 million.

MVD covers a total area of 56,600 square meters. In workshop, we configure advanced vertical and horizontal machining centers. We have 16m larger Floor Boring and Milling Machine these advanced CNC machining equipment and sophisticated detection equipments.

Our main products are: CNC Press Brake, Shears, Hydraulic press, Laser Cutter and CNC rolling machine these sheet metal processing equipments.

We are using advanced technology from German, Japan, and Italy.we can produce large Hydraulic Press and Press Brake more than 16000 ton & 16m.we are with professional R&D team, and we have World-class design and manufacturing capabilities.

We'll be unswervingly based on technological innovation, technology research and development products, Emphasis on product quality and integrity of services.

MVD have Talents in professional field to offer the installation, commissioning, training, after-sales service.Each client will get quality service on time.

We win large market at home and abroad through novel design, excellent quality and perfect after-sales service.

"Technology Innovation, China creation" is MVD's fundamental.

"Customer service, the pursuit of quality is MVD's Philosophy"

"Meet customer requirements, improve the quality continuously" is MVD's tenet.

We'll continue going beyond ourselves.

Create value for clients, and offer better technology, products and service!

FAQ

1. who are we?

We are based in Anhui, China, start from 2014,sell to Eastern Europe(16.00%),Oceania(10.00%),Western Europe(10.00%),Mid East(9.00%),North America(7.00%),South America(7.00%),Southeast Asia(7.00%),Africa(6.00%),Eastern Asia(6.00%),Northern Europe(6.00%),Central America(5.00%),Southern Europe(4.00%),South Asia(4.00%),Domestic Market(3.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shearing Machine,Press Brake,Fiber Laser Cutting Machine

4. why should you buy from us not from other suppliers?

Currently we are grouped with 8 sales companies and 110 direct sale branches to cover a national market to achieve the closest communication among groups and customers. We have also setup many sale branches in Europe, America, India, South Africa, Southeas

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese,Spanish,Portuguese

We are based in Anhui, China, start from 2014,sell to Eastern Europe(16.00%),Oceania(10.00%),Western Europe(10.00%),Mid East(9.00%),North America(7.00%),South America(7.00%),Southeast Asia(7.00%),Africa(6.00%),Eastern Asia(6.00%),Northern Europe(6.00%),Central America(5.00%),Southern Europe(4.00%),South Asia(4.00%),Domestic Market(3.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shearing Machine,Press Brake,Fiber Laser Cutting Machine

4. why should you buy from us not from other suppliers?

Currently we are grouped with 8 sales companies and 110 direct sale branches to cover a national market to achieve the closest communication among groups and customers. We have also setup many sale branches in Europe, America, India, South Africa, Southeas

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese,Spanish,Portuguese

We got 5 stars rating!

My review

Exhibition

Our serives

QUALITY CONTROL

Nearly 50 years of expertise in the manufacture of press brakes and guillotines machines give us the security that is needed for

future challenges. High standards of quality and a team with the best training and knowledgeare a major condition for our success.

Our products are the result of a continued focus on improving internal processes underpinned by high quality levels, that result

in the recognition ofAccurl' s machines as quality garantee equipment.

Nearly 50 years of expertise in the manufacture of press brakes and guillotines machines give us the security that is needed for

future challenges. High standards of quality and a team with the best training and knowledgeare a major condition for our success.

Our products are the result of a continued focus on improving internal processes underpinned by high quality levels, that result

in the recognition ofAccurl' s machines as quality garantee equipment.

Related Products

We Recommend

New Arrivals

New products from manufacturers at wholesale prices