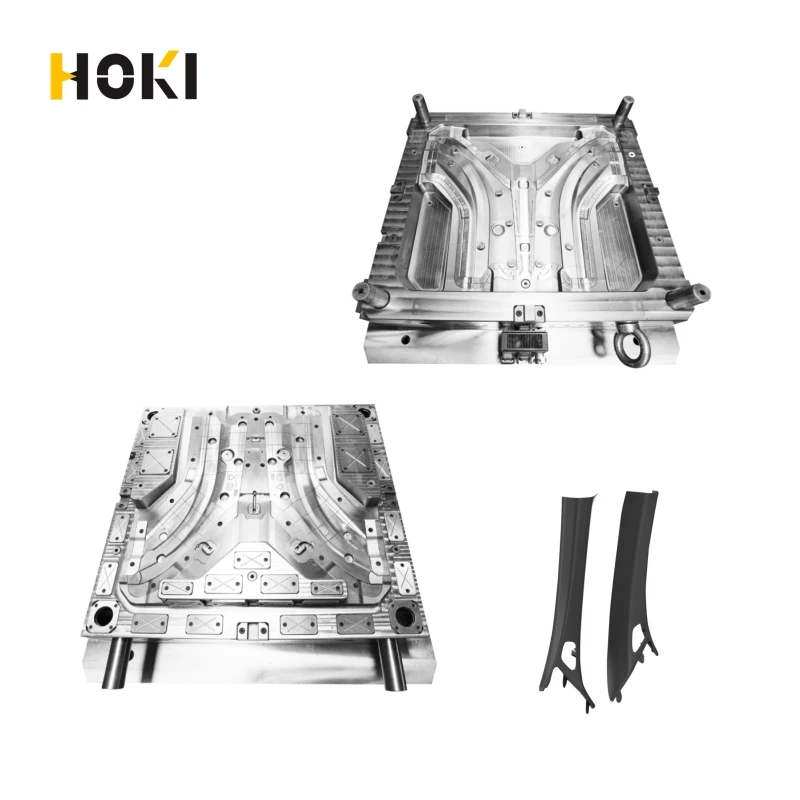

Plastic injection tooling factory for car parts plastic inner trim pillar ABC trim door trim customize components

- Category: >>>

- Supplier: Zhejiang Hoki Mold And Plastics Co. Ltd.

Share on (1601104576181):

Product Overview

Description

About HOKI

Our company is located in Taizhou, Zhejiang Province, a beautiful city in the eastern coastal region of China. Our team consists of engineers and technicians who have been immersed in mold industry for many years, and taking precision manufacturing as the leading direction, we are a well-skilled and energetic team devoting ourselves to design and manufacture of injection molds. At Hoki, you can find the one-stop service from your concept design to the product could be hold in hand.

We are certified with ISO9001:2015, and based on our rich experiences in part structure analysis, computer aided fluid analysis, product defect & deflection prediction, process optimization engineering, etc., together with our various types of CNC multi-axis simultaneous machining machines and inspection machines which with high speed, high precision, to ensure that every mold from us could meet with high standard and quality consistently.

Our main fields covering: Automobiles, Motorcycles, Home Appliances, Industrial & Household products.

|  |

Why Us

Capabilities

How we work

Quality Control

Packing: Wooden Box

Main Loading Ports: Ningbo / Shanghai

Shipping By Sea / Train / Air

FAQs

1. What should I sent to get a quote for tooling?

- We need your products in digital formats of 2D or 3D.

2. Which 3D drawing file formats do you support in digital?

- We support all the common formats like CATPart, sldprt, stl, step, stp, iges, prt, ipt, x_t, obj, etc.

3. Which 2D drawing files do you support in digital?

- We support all the common formats like dwg, dxf, pdf, tiff, svg, etc.

4. I only have samples here, can you make the mold?

- Yes, you can send your samples to us for reverse engineering.

5. How much does it cost to make a mold?

- Each mold is deeply customized according to customers’ various needs, we can quote you a reference price within 24 hours after receiving your data or sample.

6. How long does it take to manufacture the mold?

- This depends on the complexity of the mold. The more complex the mold, the longer processing time required. We will give an estimated lead time together in the quotation offered.

7. Can you help to select the plastic material for my part?

- Yes, we have rich service experiences in many different industries, suggestions on proper plastic materials could be given accordingly.

8. How do I determine which steel type should be used?

- The selection of steel type is mainly determined by the chemical properties of the plastic used for your product. We can recommend some proper steel types accordingly to the plastic you use in your project.

9. How do I know if I need a hot runner system or not? What are hot and cold runners?

- Hot runner is a commonly used auxiliary technology in the mold runner system. The use of hot runner technology in the mold can obtain better product quality and faster production cycle than when it is not used. A mold that does not have a hot runner system is correspondingly called a cold runner mold. If you are not sure whether to use or not, we will conduct professional analysis for your product to help you to find out.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices