Top Quality Methane Recovery Facility 50Hz Low Cost Membrane Separation Biogas Plant for Home

- Category: >>>

- Supplier: WOBO Industrial Group Corp.WOBO Corp.

Share on (1601110180287):

Product Overview

Description

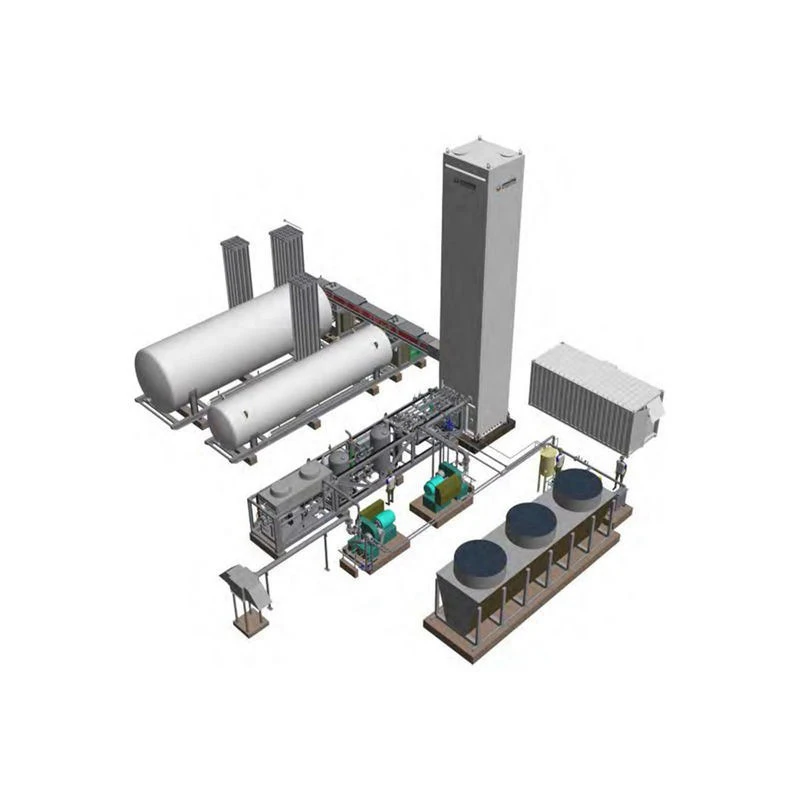

Membrane Biogas CH4 Treatment Biogas CH4 Gas Purification Unit

Long Service Life Methane Generation Machine 150Kw Low Noise Membrane Biogas Making Machine for House

Product Description

Biogas is produced through fermentation, during which microorganisms break down biomass in an anaerobic environment. Biogas typically contains 55-65% methane, 30-45% carbon dioxide, and trace gases such as hydrogen sulfide. After suitable gas pre-treatment and purification using gas separation membrane components, the purified biomethane can be injected into the natural gas supply network or further compressed into CNG to fuel vehicles. This allows customers to access environmentally friendly and carbon-neutral natural gas.

Device Name | Membrane Separation Biogas Purification System |

Device Performance | 1000~100000Nm3/h |

Methane Purity | 85~99% |

Methane Recovery Rate | 84~99% |

Application Areas | Concentration of methane from coal mine gas; purification of methane from biogas; removal of impurities above C2 from natural gas; purification of landfill gas; coal-to-gas conversion; methane enrichment in shale gas. |

Biogas produced from biogas plants is a mixture of gases containing carbon dioxide, methane, and common by-products. Initially, the mixed gas is desulfurized, filtered, and dried using activated carbon. The pre-treated gas is then fed into compressors, where it is compressed to 10-40 bar. Subsequently, it undergoes multiple stages of membrane separation to purify it, resulting in the production of biomethane and the emission of tail gas enriched with carbon dioxide. The membrane separation purification process can continuously produce high-quality biomethane, with purity levels of up to 99%. Additionally, the tail gas is exceptionally clean, with methane content well below 1%, meeting the quality standards of natural gas through this process.

The membrane separation purification system for biogas offers the following advantages:

* Methane loss during purification process is less than 1%.

* Methane yield can reach up to 99%.

* High energy utilization efficiency during purification process (biogas <0.2 kWel/Nm3, methane gas <0.4 kWel/Nm3).

* No additional auxiliary materials such as water adsorbents (amines, glycols) are needed, and there is no pressure on environmental emissions.

* Easy control and adjustment implementation when flow rate and composition change.

* After membrane purification process, biogas is already sufficiently dry and meets the dew point requirements for entry into the gas supply network.

* Scalable for both small-scale plants (10 Nm3/h) and large-scale plants (>1000 Nm3/h).

* Ability to start and stop equipment operation within short intervals ensures high flexibility.

* Can directly input (via gas pipelines) into the gas supply network without the need for additional compressors.

* Methane yield can reach up to 99%.

* High energy utilization efficiency during purification process (biogas <0.2 kWel/Nm3, methane gas <0.4 kWel/Nm3).

* No additional auxiliary materials such as water adsorbents (amines, glycols) are needed, and there is no pressure on environmental emissions.

* Easy control and adjustment implementation when flow rate and composition change.

* After membrane purification process, biogas is already sufficiently dry and meets the dew point requirements for entry into the gas supply network.

* Scalable for both small-scale plants (10 Nm3/h) and large-scale plants (>1000 Nm3/h).

* Ability to start and stop equipment operation within short intervals ensures high flexibility.

* Can directly input (via gas pipelines) into the gas supply network without the need for additional compressors.

Project Case

PROJECT CASE

Capacity: 240,000 Nm3/day

C3+ removal: 80%

PROJECT CASE

Application: natural gas

Capacity: 8,000 Nm3/day

C3+ removal: 80%

PROJECT CASE

Capacity: 300,000 Nm3/day

CO2 reduction from 50% to 10%

PROJECT CASE

Capacity: 1300,000 Nm3/day

CO2 reduction from 40% to 2%

Product Application

Related Products

Biomethane whole industry chain products

It mainly includes biogas produced by anaerobic fermentation of animal and plant dung (black membrane biogas digester, red mud biogas digester, anaerobic digestion system), industrial and commercial agricultural organic fertilizer production, biogas power generation, biomethane-RNG grid injection, CNG storage system, LNG storage system, CNG mobile/skid filling station and transportation, LNG skid filling station, biological natural gas liquefaction and other products.

Biogas EPC turnkey project

The biogas EPC turnkey project involves starting with the collection and pretreatment of organic waste, producing biogas through anaerobic fermentation, followed by purification treatment to remove impurities, and finally storage and utilization of the purified biogas. The EPC turnkey project covers the whole process from engineering design, equipment procurement, construction to system commissioning and operation and maintenance to ensure the efficient operation of the project and reach the expected capacity.

Company Profile

We Recommend

Cryogenic air Separation Unit Gas with Two Columns Oxygen Nitrogen Producing Manufacturers

$170,000.00-180,000.00

New Arrivals

New products from manufacturers at wholesale prices