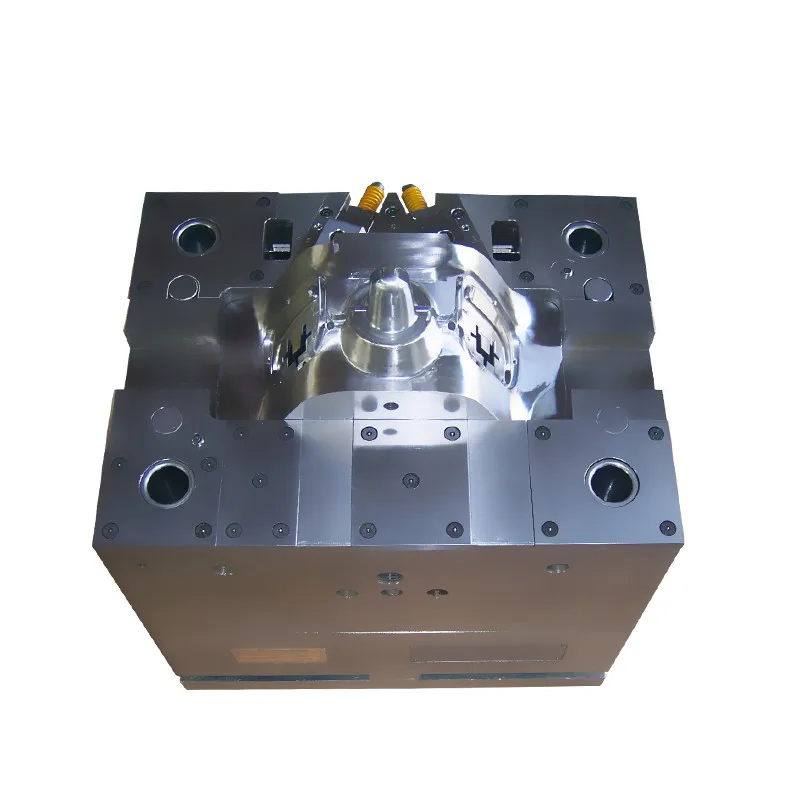

Custom injection molding for coffee machine housing shell new design injection mold plastic injection mold

- Category: >>>

- Supplier: Ningbo Moldor Plastic Co. Ltd.

Share on (1601115734929):

Product Overview

Description

QUALITY FIRST & SERVICE FIRST & CUSTMER FIRST is our aim,MAKE EVERY PROJECT A SUCCESS is our mission.We sincerely hope to be your trustworthy partner for long-termcooperation.

Cycle Time | 15-45days |

Mould Life | 300000-500000 times |

Design Software | UG,PROE,CATIA,SOLIDWORK,CAD and etc. |

Runner | Cold runner or hot runner as customer required |

Mould Cavity | Single or multi as customer required |

Mold Material | P20, NAK80, H13, S45C, 718H,718 etc. |

Mold Base Material | LKM C45, S50C, 45#, S55C |

Plastic material | PP,PC,PS,PAG,POM,PE,PU,PVC,ABS,PMMA,etc |

Surface | Mirror polish, Frosted, Textured or as customer required Manufacturing Machines:CNC, EDM, Milling, Wire-cut, etc. Mold Standard: Domestic standard, Hasco standard, DME standard. |

Mold testing | We supply free product trial before shipment. |

Place of Origin | Zhejiang, China (Mainland) |

Make your own molds in MOLDOR PLASTIC !

1. In-house mold design and building capabilities to

improve work efficiency.

2. NDA agreement can be signed to protect customers'

idea and design.

3. Professional sales team. Good communication skills

and after service.

4. Professional design team, mold maker engineer.

OEM/ODM service.

5. Professional QC and R&D teams to assure high quality.

6. In time response to letters and emails.

7. On time delivery.

......

Custom Plastic Injection Mold

According to your drawings or samples, we can provide one-stop solutions service from designing, prototyping, molds

making, processing, spraying, assembling, inspecting, packaging to delivering, everything will be managed to the smallest

detail.

If you have products or ideas that require injection mold & molding, Moldor Plastic would like to serve you. Our knowledgeable engineers and designers will offer suggestions on how to manufacture your product to allow for a professional look as well as for ease of manufacturing. We are committed to providing personal service at the lowest possible prices to you.

1. Manufacturing experience for over 15 years.

2. Customized designs and services are accepted.

Professional design team and engineering team offer

technical support.

3. Manufacturing process control.

4. Small volume production or mass production is available.

5. Trained workers and professional QC team to assure the

product quality.

6. Inspection report and material test certificates are

available upon requests.

7. Standard: HASCO or as customer's requirement.

......

Please kindly send your inquiry to us, and our professional team will offer you competitive price with excellent quality.

Your any inquiry is welcomed and will be replied soon.

Product Design: We provide product

design service & suggestion as

customers' request.

Mold Design: We communicate & exchange the detail information with our customers to make a good mold design.

Mold Making: Manufacturing in-house, we send the mold processing photos and videos to customers.

Mass Production: We start plastic injection parts production after customers

confirm samples.

Assembly: We can supply assembly service as customers' requests.

Value added Service: Available, such as screen printing, plating, custom

packaging and etc.

Factory price makes your cost

transparent

Strong engineering support with

drawings or samples.

Over 15 years' experience

Offer one-stop service and

after-service

Equipped with high precision imported machines

100% strict high quality control

Q1:Are you a trading company or factory?

A1:We are factory.

Q2:What type of information is required for quoting a molding project?

A2:Please send your drawings or sample to us.

Q3:How long do you take to build a mold?

A3:The production timeline depends on your specific needs, normally the lead time is 25-45days.

Q4:How small or large of a plastic part will you produce?

A4:Our machine capabilities cover a range from 60-ton to 500-ton clamping forces.

Q5:What kind of steel do you use for plastic moldings?

A5:We can use any type of steel appointed by customer or popular in the market.Such as P20,718,8407,NAK80,H13,S136,

DIN 1.2738,DIN 1.2344,etc.

Q6:What types of materials can be molded by your injection products?

A6:Polystyrene,ABS,PET,TPR,TPU,PVC,Nylon,Acetal,Polypropylene,Polyethylene, Polycarbonates and etc.

Q7:Do you offer secondary service such as assembly, packaging or painting?

A7:Yes,such as assembly, painting, tapping, ultrasonic welding, trimming, sorting, customized packaging and etc.

Q8:If I have an existing tooling, could you use it to mold my project?

A8:Most certainly, if existing tooling is available, we can use them.

Q9:Can you mold around inserts or metal components?

A9:We can do insert molding with just about any metal and non-metal components.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices