Fast process surface JC MK19A12 internal roller burnishing tool on lathe

- Category: >>>

- Supplier: Taizhou Ke Chi Machinery Co. Ltd.Taizhou Ltd.

Share on (1601121843799):

Product Overview

Description

Fast process surface JC-MK19A12 internal roller burnishing tool on lathe

Introduction

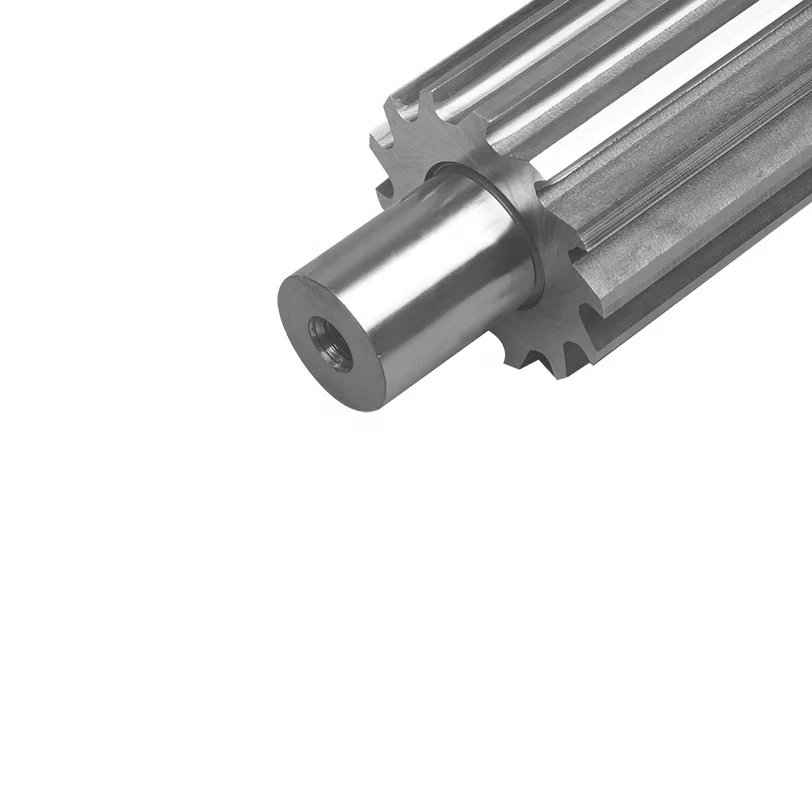

The roller burnishing tool can utilize the plastic deformation of the metal at normal temperature to smooth the micro roughness of the workpiece surface so as to change the surface structure, mechanical characteristics, shape and size. The Roller burnishing tool is a mechanical, non cutting, plastic processing method that uses mechanical extrusion to obtain a smooth, mirror like surface of a metal.Due to the burnish surface of metal plastic deformation, so that the surface microstructure of cold hardening and grain refinement, forming a dense fibrous, and the formation of residual stress, hardness and strength increase, thereby improving the wear resistance of the workpiece surface.

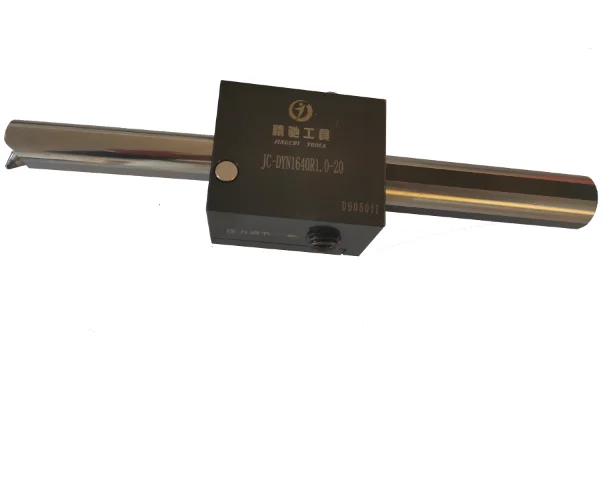

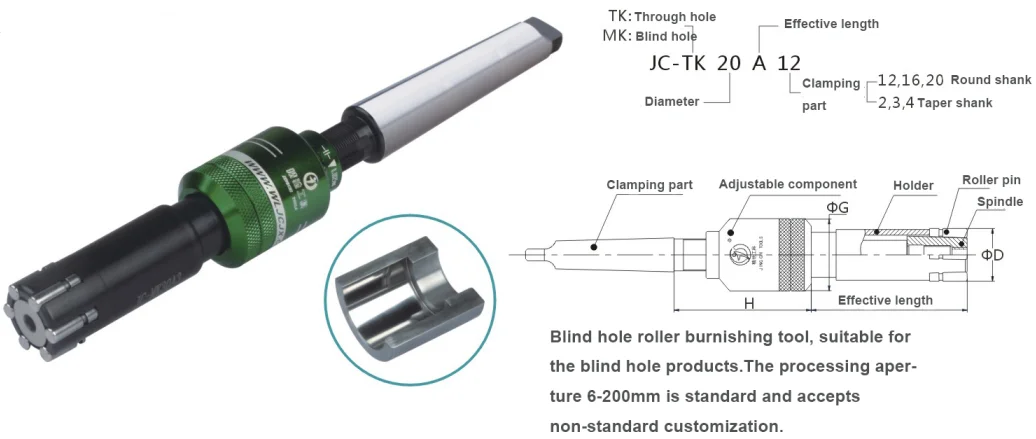

JC-MK Blind hole roller burnishing tool

Application cases: cylinder block, motor stator, connecting rod, valve body, rocker arm, etc

Optional Parameters(mm)

Model | Regulating component, Diameter and adjustment range | Effective Length/L | Shank/H | |||||||

ΦD | ΦG | Through hole/ Blind hole | A | B | C | D | Round shank | H | Taper shank | H |

Φ4.5-Φ5 | HA0 | -0.05/+0.15 | 50 | 80 | _ | _ | Φ12*40 | 78 | MT2 | 68 |

Φ6-Φ8 | -0.05/+0.25 | 100 | _ | |||||||

Φ9-Φ11 | -0.05/+0.4 | 130 | ||||||||

Φ12-Φ16 | HA1 | -0.1/+0.5 | ||||||||

Φ17-Φ19 | 60 | 90 | 110 | 140 | ||||||

Φ20-Φ25 | HA2 | -0.1/+0.5 | 70 | 100 | 120 | 150 | 88 | 78 | ||

Φ26-Φ39 | 80 | 130 | 180 | 230 | Φ12*40 | MT2 | ||||

Φ40-Φ45 | 0/+0.5 | 150 | 200 | 250 | 300 | |||||

Φ46-Φ68 | HA3/45 | 160 | 210 | 260 | 310 | 100 | 88 | |||

Φ70-Φ200 |

| -0.1/+0.5 | _ | _ | MT3/4/5 | 95 | ||||

Aperture 26mm-68mm of the rolling knife, effective processing length from the beginning of B files, shank standard MT3.If you need other models, specifications to be customized. Because the outer diameter of the adjusting component is smaller than that of the machining aperture, the processing length can be increased by lengthening the size of the handle part of the 40mm.

Accessory(Roller pin and Spindle)

Jingchi tool is the only special surface treatment for roller pin and spindle In china. The surface roughness of the roller pin and spindle produced is 1~2 higher than that of the same kind of products, which makes the tool less friction loss and longer service life. It has international quality and high performance price ratio.

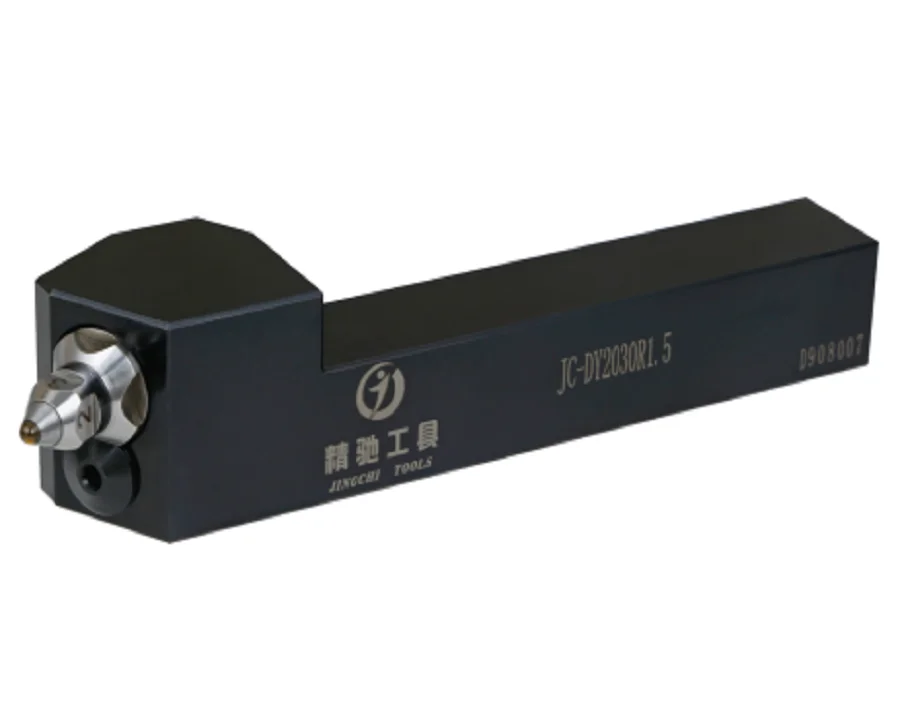

TaiZhou KeChi machinery Co.,Ltd is a company specialising in the production of mirror roller burnishing tools, rotary broach tools, knurling tools, combined skive-burnishing tool, diamond burnishing tool.And setting research and development production,sales in one integrated manufacturers.The company has its own R & D team and after-sales service team,.It focus on the mirror roller burnishing, rotary broach, knurling and other technical areas. During the past ten years, it has provided perfect solutions for thousands of customers in auto parts, aerospace, hydraulic, cylinder, ship, construction machinery, medical, agricultural machinery, air conditioning,motor and so on.

Our certificate

Workshop

Test equipment

Exhibition

1. Feedback within 2 hours

2. Professional suggestion on product;

3. Could issue the C/O(certificate of origin)to customer to reduce the tax;

4. Could accept payment terms of T/T, L/C, western union, paypal and etc.

1.You are traders or manufacturers?

A: We are a factory. you are most welcomed to visit us

2.Q:What is the material of your products?

A: The material is mainly steel,Cast iron(Ductile cast iron) We can also choose material as customer requirements.

3.What is the artwork of your products,can print our logo?

A: Yes,we can provide your logo.

4.Q: What is your MOQ ?

A: 1 set per style.

5.Q: What is the lead time?

A: It depends on your order quantity.

6.Q: What are your payment terms?

A: 30% deposit and balance T/T before shippment or L/C at sight.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices