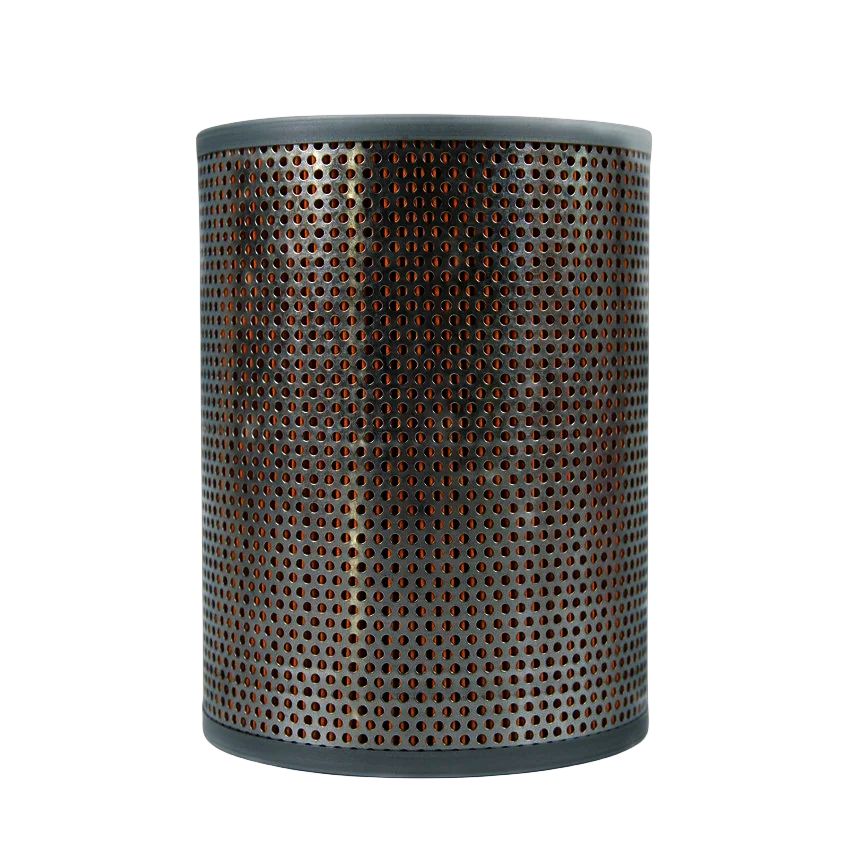

High filtration rates Mining Rotary drum filter machine ceramic disk vacuum filter

- Category: >>>

- Supplier: Qingdao Greatree International Trading Co. Ltd.

Share on (1601123161200):

Product Overview

Description

Overview

Video Description

Products Description

-Eco-friendly

The traditional grease-lubricated bearings (including both rolling contactbearings and sliding contact bearings) are

replaced with self-lubricating sliding contact bearings, eliminating the pollution hazard to both thetransmission medium and the

site environment.

-Energy-saving

A. Lubricant is no longer needed. B. Less material used. C. Increased efficiency.

-Maintenance-free and low operation cost

A. Maintenance-free bearing eliminates manual inspection.

B. The non-driving end seal adopts static seal technique,eliminating one mechanical seal.

-Longer bearing life

The service life of traditional ball bearings is affected by the operating conditions. The general design life is about 2-5 years.

With this product,the bearing service life can reach 5-10 years.

-Safer, smoother, and more reliable operation

A. Carefully designed to reduce vibration and noise.

B. The non-driving end adopts static sealing, which reduces onepoint of failure.

C. The bearing cage of the traditional double-suction pump isremoved, the length of the pump shaft is shortened, improving the operational stability of the pump.

D. Diaphragm coupling for the full range of pumps.

replaced with self-lubricating sliding contact bearings, eliminating the pollution hazard to both thetransmission medium and the

site environment.

-Energy-saving

A. Lubricant is no longer needed. B. Less material used. C. Increased efficiency.

-Maintenance-free and low operation cost

A. Maintenance-free bearing eliminates manual inspection.

B. The non-driving end seal adopts static seal technique,eliminating one mechanical seal.

-Longer bearing life

The service life of traditional ball bearings is affected by the operating conditions. The general design life is about 2-5 years.

With this product,the bearing service life can reach 5-10 years.

-Safer, smoother, and more reliable operation

A. Carefully designed to reduce vibration and noise.

B. The non-driving end adopts static sealing, which reduces onepoint of failure.

C. The bearing cage of the traditional double-suction pump isremoved, the length of the pump shaft is shortened, improving the operational stability of the pump.

D. Diaphragm coupling for the full range of pumps.

PRODUCT INTRODUCTION

Disk vacuum filter uses vacuum as its filtering power to carry out solid-liquid separation of pulp.

Unloading by anti- blowing, variable speed agitating, and automatic centralized lubrication and other advanced technologies make it to be the dehydration equipment with good performance and reliable application.

Unloading by anti- blowing, variable speed agitating, and automatic centralized lubrication and other advanced technologies make it to be the dehydration equipment with good performance and reliable application.

This machine is the new type disk vacuum filter exclusively designed for the dehydration of iron or concentrate and non-ferrous metal ore. It also applies to coal washing plant, as well as non-metal ores, chemical industry and

environmental protection operation.

environmental protection operation.

Product Paramenters

PRODUCTION MODEL

Only some models are shown,please contact us for more parameters.

Company Profile

Our Mineral processing and smelting research institute has undertaken thousands of experimental research projects in various minesat home and abroad. In particular, nearly one hundred scientific tests have been carried out on the mines with low grade and refactory ore. The institute now has more than 30 processing, research and development personnel. and possesses national leading technology in gold research

Meanwhile, we obtained a number of scientific research achievements ,in recent years, we also made a major breakthrough in the field of non-metallic, particularly in fluorite ore, graphite ore, quartz, sodium potassium feldspar ore dressing research, which obtained a number of proprietary technology.

Meanwhile, we obtained a number of scientific research achievements ,in recent years, we also made a major breakthrough in the field of non-metallic, particularly in fluorite ore, graphite ore, quartz, sodium potassium feldspar ore dressing research, which obtained a number of proprietary technology.

FAQ

Q: How can I make order online?

A: Send email or message(whatsApp/ wechat) us.you can ask any question ,after we confirm the detail, we can make order.

Q: Do you have MOQ limit? A: The MOQ is 1 set. Q: Which payments are acceptable?

A: T/T, L/C, Western Union, Paypal, Alibaba Trade Assurance.

Q: Which shipping terms are available?

A: By sea, air, Express

Q: How about the delivery time?

A: Delivery time is normally 3-7 working days after confirm the money. Depends on your quantity.

Q: What's your warranties?

A: 1 year after delivery

A: 1 year after delivery

Q: Can I buy parts separately?

A: Yes, all of the pump spare parts can buy separately.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices