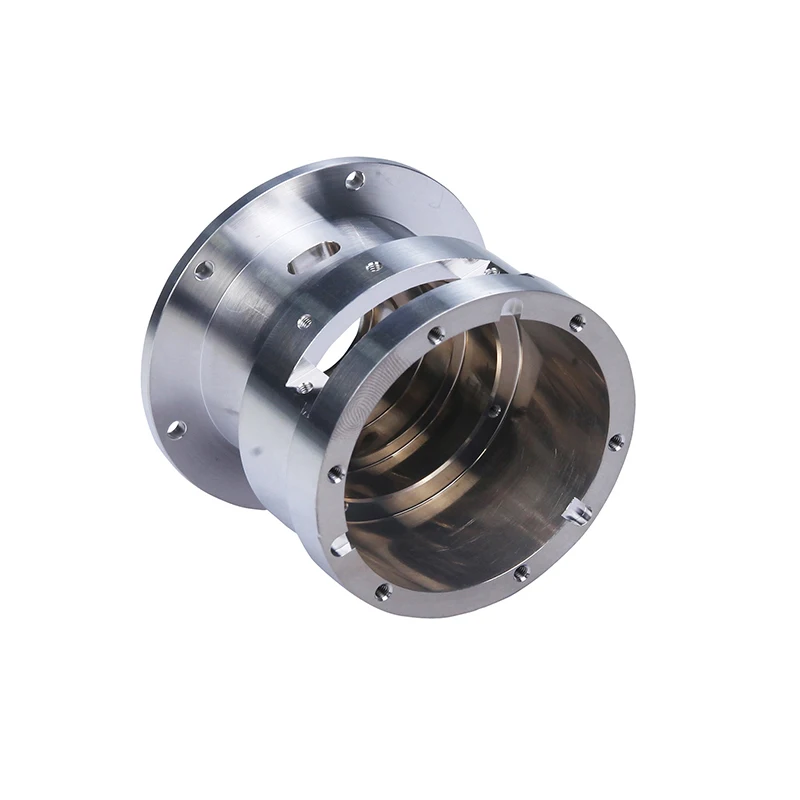

CNC Milling Parts Custom Metal CNC Positioning Guide Shaft CNC Machining Fabrication steel forging large shaft End Cap

- Category: >>>

- Supplier: Puruote (Shenzhen) Industrial Products Co. Ltd.

Share on (1601126576002):

Product Overview

Description

Product Description

Specification

Part Name | CNC China Shop Customized Parts Service |

Plastic Materials | ABS,PMMA,PC,POM,Steel, aluminum,stainless steel, copper..etc. |

Process | CNC Milling/Machining/Turning ect |

Production Leadtime | 3-5 days |

Company Profile

Attention: We are custom-made manufacturers of various parts according to customer requirements. The product pictures only show

that we have the ability to produce similar products, and do not really sell this product.

For any new inquirys,please send us 3D stp/igs/stl format design files,and tell us the part material,quantity and surface finish

requirements for quotation by email as follow:

PROTO INDUSTRY MANUFACTORY LTD

E-mail : info@protoindustry.com

Web: www.protoindustry.com

About us:

Proto Industry Manufactory custom-made manufacturers of various parts according to customer

requirements,Leading CNC Machining Parts Service,R&D Rapid Plastic and Metal Prototyping,Plastic mold and injection production,Sheet Metal Parts,Silicone Rubber Parts manufacturer in Shenzhen city, China. we serve a wide range of industrial, including household application, auto, electronic,

medical, agriculture etc.

Our services include:

* Product ID & MD design

* Customized design various parts

* CNC machining parts

* Vacuum casting parts

* Small volume production

* Mold design flow analy DFM report

* Custom Plastic mold, Hot compression Mold and Stamping Molds

* Plastic injection molding,Hot compression and stamping punching process

* Polish,Matte,Spray Painting, silk screen,anodizing , chrome plated and assembly ect

As the most valuable assets, Proto Industry people have been always the key of our success in the past decades, currently we have

80 well trained product makers employed, 10 experienced senior engineers and 6 ID& MD designers, Proto Industry people guarantee

you high quality and stable performance!

To satisfy our customers' highest requirements, we invest on the latest technology continuously and equipped the most advanced

mold manufacturing facilities, we have full in-house plastic and metal parts manufacturing, plastic injection molding, painting,

assembly capacity, our equipment includes : 20 sets of CNC Machines, precision 0.005mm, 8 sets of mirror EDM Machines, 5 sets of

slow wire cut, 38 sets injection molding machines range from 50 to 800 Tons, 2 set of 2D projection measurement, 1 set of CMM. We

can custom made various sample parts to verify design and doing mass production as well, we are able to build plastic mold and

die-casting maximum 7.5 tons, molded plastic parts Maximum 1200g. We also utilized the advanced CAD/CAM/CAE system, we can work

with data in pdf, dwg, dxf, igs, stp etc. We always learn and adopt the latest technology to keep our advance. well organized

management system ensure us to provide stable performance, punctual delivery, competitive price, efficiency communication,

flexible to meet customer's most urgent needs.

We are prepared to be challenged, looking forward to get involved in your next project !

that we have the ability to produce similar products, and do not really sell this product.

For any new inquirys,please send us 3D stp/igs/stl format design files,and tell us the part material,quantity and surface finish

requirements for quotation by email as follow:

PROTO INDUSTRY MANUFACTORY LTD

E-mail : info@protoindustry.com

Web: www.protoindustry.com

About us:

Proto Industry Manufactory custom-made manufacturers of various parts according to customer

requirements,Leading CNC Machining Parts Service,R&D Rapid Plastic and Metal Prototyping,Plastic mold and injection production,Sheet Metal Parts,Silicone Rubber Parts manufacturer in Shenzhen city, China. we serve a wide range of industrial, including household application, auto, electronic,

medical, agriculture etc.

Our services include:

* Product ID & MD design

* Customized design various parts

* CNC machining parts

* Vacuum casting parts

* Small volume production

* Mold design flow analy DFM report

* Custom Plastic mold, Hot compression Mold and Stamping Molds

* Plastic injection molding,Hot compression and stamping punching process

* Polish,Matte,Spray Painting, silk screen,anodizing , chrome plated and assembly ect

As the most valuable assets, Proto Industry people have been always the key of our success in the past decades, currently we have

80 well trained product makers employed, 10 experienced senior engineers and 6 ID& MD designers, Proto Industry people guarantee

you high quality and stable performance!

To satisfy our customers' highest requirements, we invest on the latest technology continuously and equipped the most advanced

mold manufacturing facilities, we have full in-house plastic and metal parts manufacturing, plastic injection molding, painting,

assembly capacity, our equipment includes : 20 sets of CNC Machines, precision 0.005mm, 8 sets of mirror EDM Machines, 5 sets of

slow wire cut, 38 sets injection molding machines range from 50 to 800 Tons, 2 set of 2D projection measurement, 1 set of CMM. We

can custom made various sample parts to verify design and doing mass production as well, we are able to build plastic mold and

die-casting maximum 7.5 tons, molded plastic parts Maximum 1200g. We also utilized the advanced CAD/CAM/CAE system, we can work

with data in pdf, dwg, dxf, igs, stp etc. We always learn and adopt the latest technology to keep our advance. well organized

management system ensure us to provide stable performance, punctual delivery, competitive price, efficiency communication,

flexible to meet customer's most urgent needs.

We are prepared to be challenged, looking forward to get involved in your next project !

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

FAQ:

1.Are you a manufacturer or a trading company?

We are a 20000-square-meter factory located in Shenzhen, China.

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 2-3 days for prototype sample,Mold time is 2-4 weeks for T1 samples, 1 weeks for mass production.

7. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

1.Are you a manufacturer or a trading company?

We are a 20000-square-meter factory located in Shenzhen, China.

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 2-3 days for prototype sample,Mold time is 2-4 weeks for T1 samples, 1 weeks for mass production.

7. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices