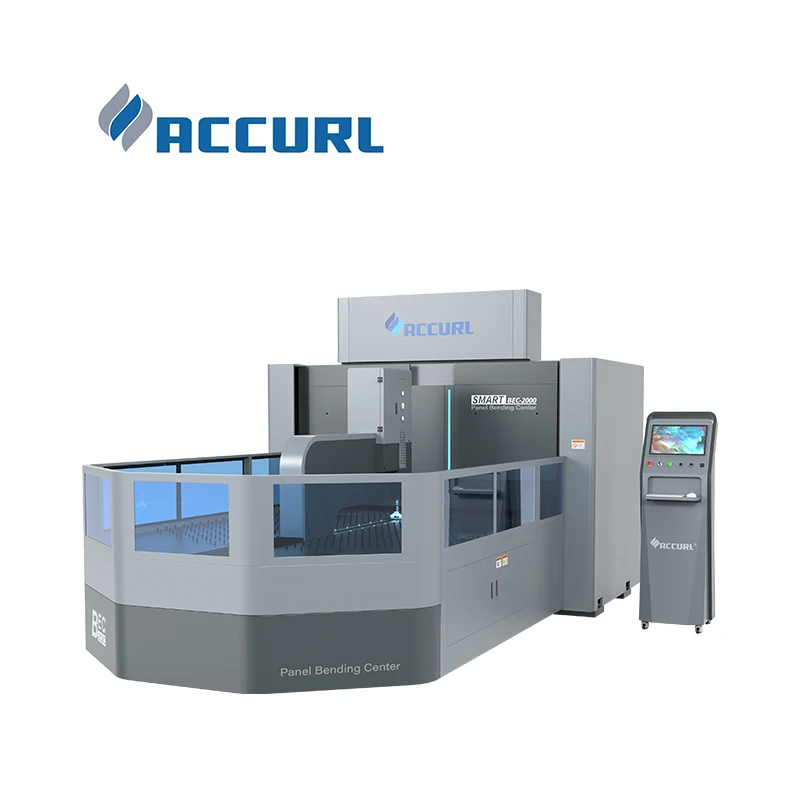

AccurL Full Automatic CNC Panel Bender Competitive Price Sheet Metal Folding Machine Press Brake for Panel Bending

- Category: >>>

- Supplier: Accurl Cnc Machine(anhui) Manufactory Co. Ltd.

Share on (1601137366228):

Product Overview

Description

Products Description

ACCURL BEC Series Automatic Panel Bender Center

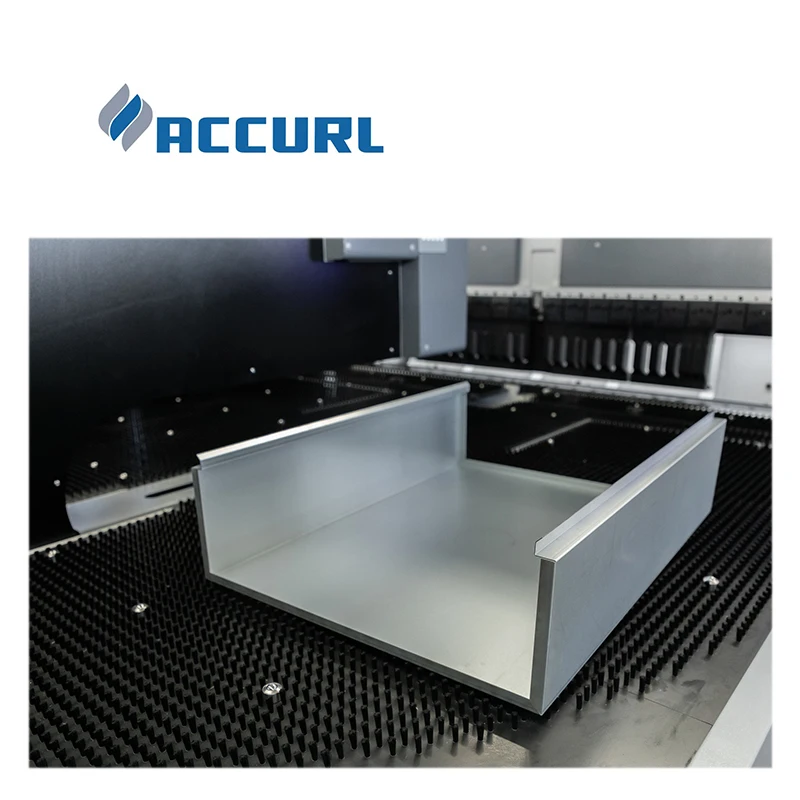

PBESeries panel bender is the new generation automated bending solutions, a benchmark that indicates the upgrading to automation of sheet metal fabricating industry. It can obviously reduce the labor cost and at the same time it can realize 300% higher efficiency comparing to traditional press brake up to 0.3s per bending. Full electro servo transmission plus closed-loop BUS control makes the accuracy far better.

The multilateral bending center does not need to change the mold, the working stroke is short, and the feed is fast.Comprehensive efficiency is 3 to 4 times that of manual bending machine.According to the bending process, it can be automatically folded up and down, so as to realize the bending of arcs, dead edges,and various angles.Highly intelligent operation control system, which can efficiently bend different workpieces.Energy saving and consumption reduction, reducing labor and mold costs.

Details Images

CNC CONTROL SYSTEM

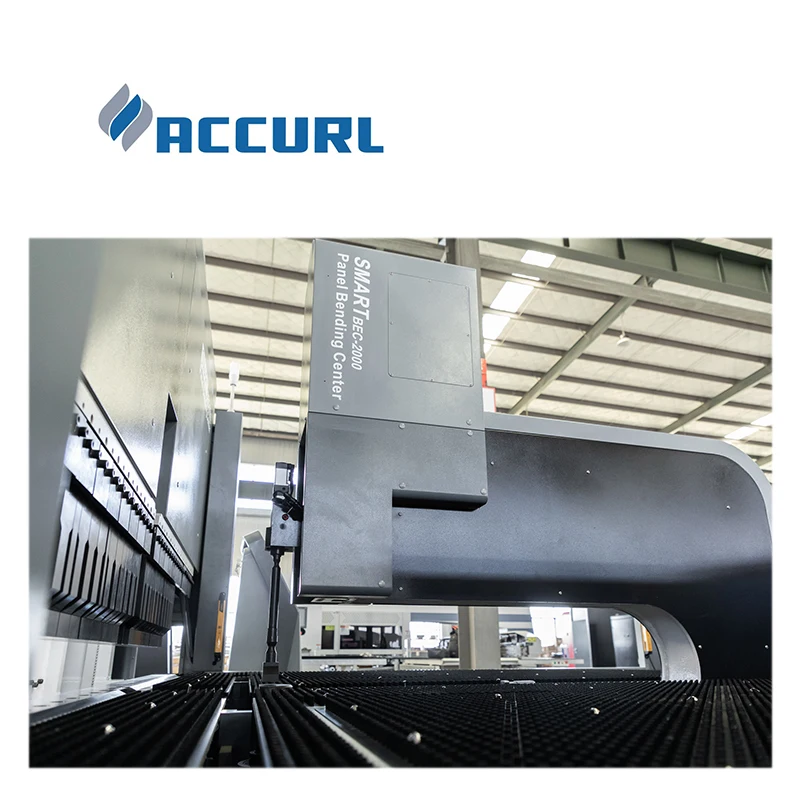

In view of the high-intensity motion requirements of the panel bender, the frame adopts an arch design, which is thickened and widened.The frame is tempered, annealed and aged twice to ensure the long-term running accuracy, stability and high rigidity of the machine.

SYNTEC System Functions and Features:

1.16-axis linkage, BUS CNC controller

2.Industrial controller, stable quality, in line with various standards

3.Bus absolute servo motor

4.Good openness and high adaptability

2.Industrial controller, stable quality, in line with various standards

3.Bus absolute servo motor

4.Good openness and high adaptability

The Software Features:

1.Order-style graphic programming, easy to use

2.Real-time display of programming bending results, what you see is what you get

3.The processing speed is fast, and the distance of retraction and rotation is automatically matched for workpieces of different sizes

4.Support a variety of processes, complex angles/hemming/arcs/special actions and other complex actions can be formed in one step

5.Support various process parameters and automatic matching compensation module

6.Support torque limit function, protect the life of the machine while ensuring the compression of the workpiece

7.Support handwheel simulation function to ensure that there will be no interference and collision during the debugging process

8.Support 3D graphics import function in step format, start processing after direct import

2.Real-time display of programming bending results, what you see is what you get

3.The processing speed is fast, and the distance of retraction and rotation is automatically matched for workpieces of different sizes

4.Support a variety of processes, complex angles/hemming/arcs/special actions and other complex actions can be formed in one step

5.Support various process parameters and automatic matching compensation module

6.Support torque limit function, protect the life of the machine while ensuring the compression of the workpiece

7.Support handwheel simulation function to ensure that there will be no interference and collision during the debugging process

8.Support 3D graphics import function in step format, start processing after direct import

Function Configuration

Name | Configuration |

Feeding Type | Arm Hold Dual Rotate |

Table Type | Brush |

CNC Axes | 11 |

Speed Adjustment | Standard |

Senior Command | Standard |

Arc Command | Standard |

HEM Command | Standard |

Robot Connection | Standard |

FEATURE-MULTI POSITIONING WAYS

The frame is welded by carbon dioxide shielded welding, which has many advantages such as stable welding process, no internal

defects, and minimal spatter.

defects, and minimal spatter.

The frame adopts a high-precision temperature-controlled furnace, which is tempered, heat-treated, annealed and modulated according to the temperature curve corresponding to the material, which ensures the lasting stability of the overall accuracy of the machine tool.

Main Components Configuration

Item | Description | Brand | |

1 | No | HC15E-S Touch Screen | SYNTEC |

2 | Servo Driver | BUS Control | SYNTEC |

3 | Servo Motor | H & F Series | SYNTEC |

4 | Motor Reducer | SIGRINER | |

5 | Ball Screw | Heavy Load | YIGONG |

6 | Bearing | NACHI | |

7 | Linear Guide | HIWIN/PMI | |

8 | Coupling | MIKIPULLEY | |

9 | Lubrication System | BAOTN | |

10 | Electric Component | Schneider | |

11 | Pneumatic Component | AirTAC/JULY |

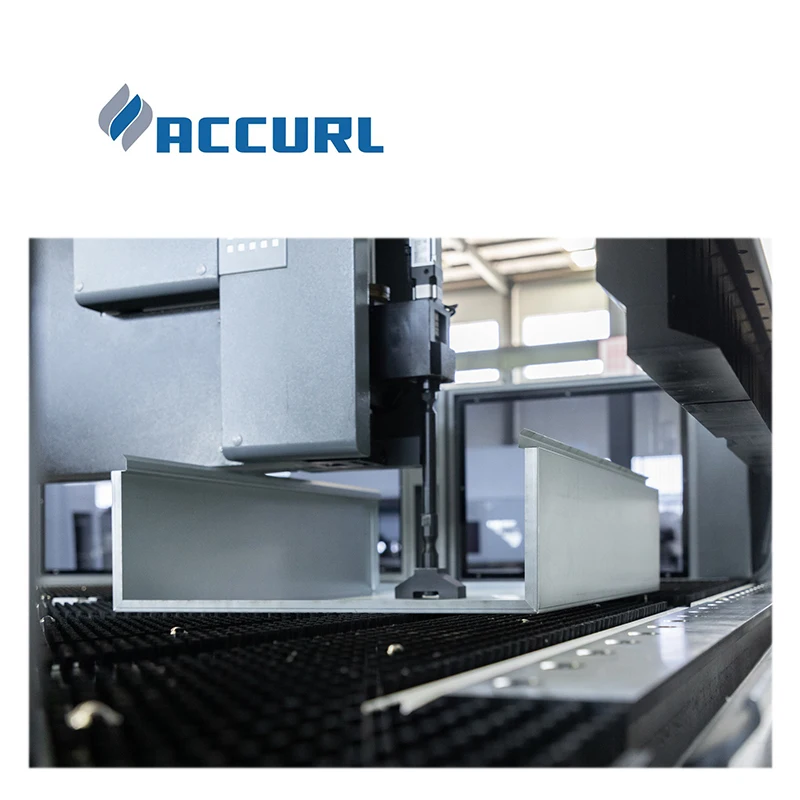

FEATURE-AUTOMATIC CORRECTION OF ROTATION ANGLE

The arc bending process requires repeated bending of the plate. If the rotation angle is not in place, the bending error will

accumulate each time, resulting in the folded workpiece is not an arc, but a cone.

The automatic correction function can automatically adjust the C/C11 axis to compensate for sheet rotation errors.

accumulate each time, resulting in the folded workpiece is not an arc, but a cone.

The automatic correction function can automatically adjust the C/C11 axis to compensate for sheet rotation errors.

CNC AXES-11 AXES

*lA/B axes: Positioning axes

*lV axis: Feeding axis

*lC/C11 axes: Rotation axes

*lW/W11 axes: Pressing axes

*lZ/Z11 axes: Tooling up&down motion axes

*lY/Y11axes : Tooling forward&dbackward motion axes

*lV axis: Feeding axis

*lC/C11 axes: Rotation axes

*lW/W11 axes: Pressing axes

*lZ/Z11 axes: Tooling up&down motion axes

*lY/Y11axes : Tooling forward&dbackward motion axes

SERVO SYSTEM

The pure electric servo fully closed-loop system is adopted, and the system supports up to 16 axes concurrent linkage, so that the bending action is smooth, the mechanical operation is highly coordinated, and the combination of various complex actions can be smoothly realized. The whole machine has high working efficiency and low daily maintenance workload. It has a self-lubricating system for the whole machine. When the oil amount is lower than the specified value, the system will automatically alarm. Just follow the program prompts to add lubricating grease.

Related Products

Company Profile

Why choose us?

ACCURL is a famous manufacturer of metal sheet equipments in world market. Its Brand "Accurl" has been leading brand for many years in the field of international metal sheet equipments. Our group devote ourselves to product development, production and sales. Our main products are: CNC Press Brake, Shears, Hydraulic press, Laser Cutter and CNC rolling machine these sheet metal processing equipments.we are using advanced technology from German, Japan, and Italy.we can produce large Hydraulic Press and Press Brake more than 5000 ton & 20m.we are with professional R&D team, and we have World-class design and manufacturing capabilities.Our production base lies in Bowang equipment industrial park, which is "China edge molding machine first town".

Technological Process

We Got 5 Stars Rating!

Exhibition

Production Power

The Robot Arm

OEM Press Brake

OEM Press Brake

Our American dealers came to visit the factory

Product packaging

1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2.All the spare parts of themachine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

Our serives

QUALITY CONTROL

Nearly 50 years of expertise in the manufacture of press brakes and guillotines machines give us the security that is needed for future challenges. High standards of quality and a team with the best training and knowledgeare a major condition for our success.

Our products are the result of a continued focus on improving internal processes underpinned by high quality levels, that result in the recognition ofAccurl' s machines as quality garantee equipment.

Our products are the result of a continued focus on improving internal processes underpinned by high quality levels, that result in the recognition ofAccurl' s machines as quality garantee equipment.

FAQ

1.Can you supply the relevant documentation?Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices