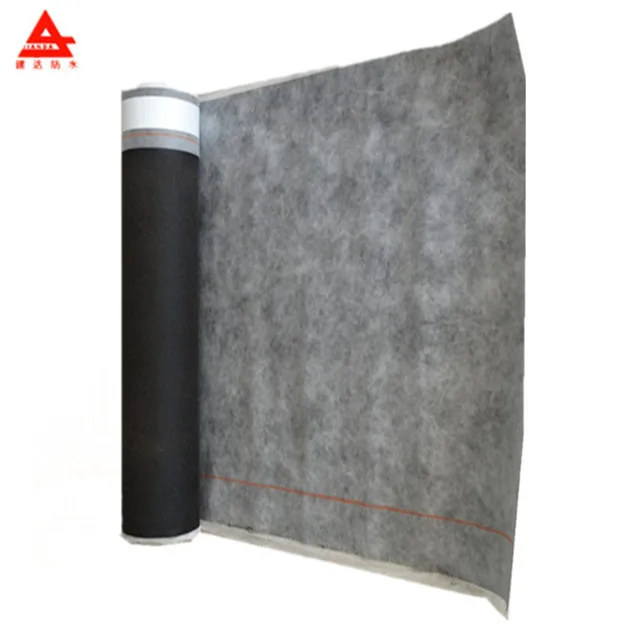

100% Waterproof Construction Roll Uncoupling Membrane 1x10m 1x20m 1x30m

- Category: >>>

- Supplier: Hangzhou Tyco Industrial Co. Ltd.

Share on (1601142744361):

Product Overview

Description

Product Description

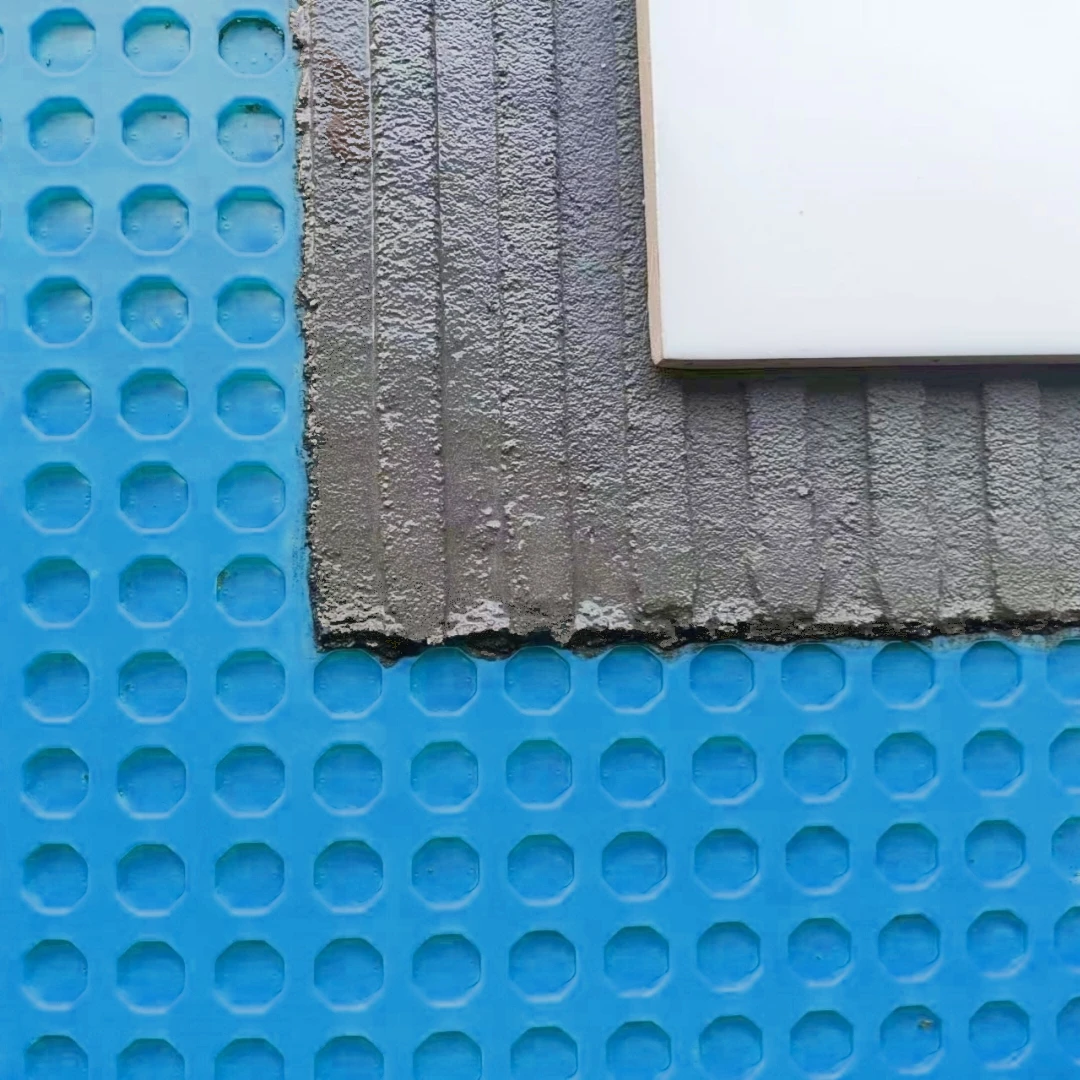

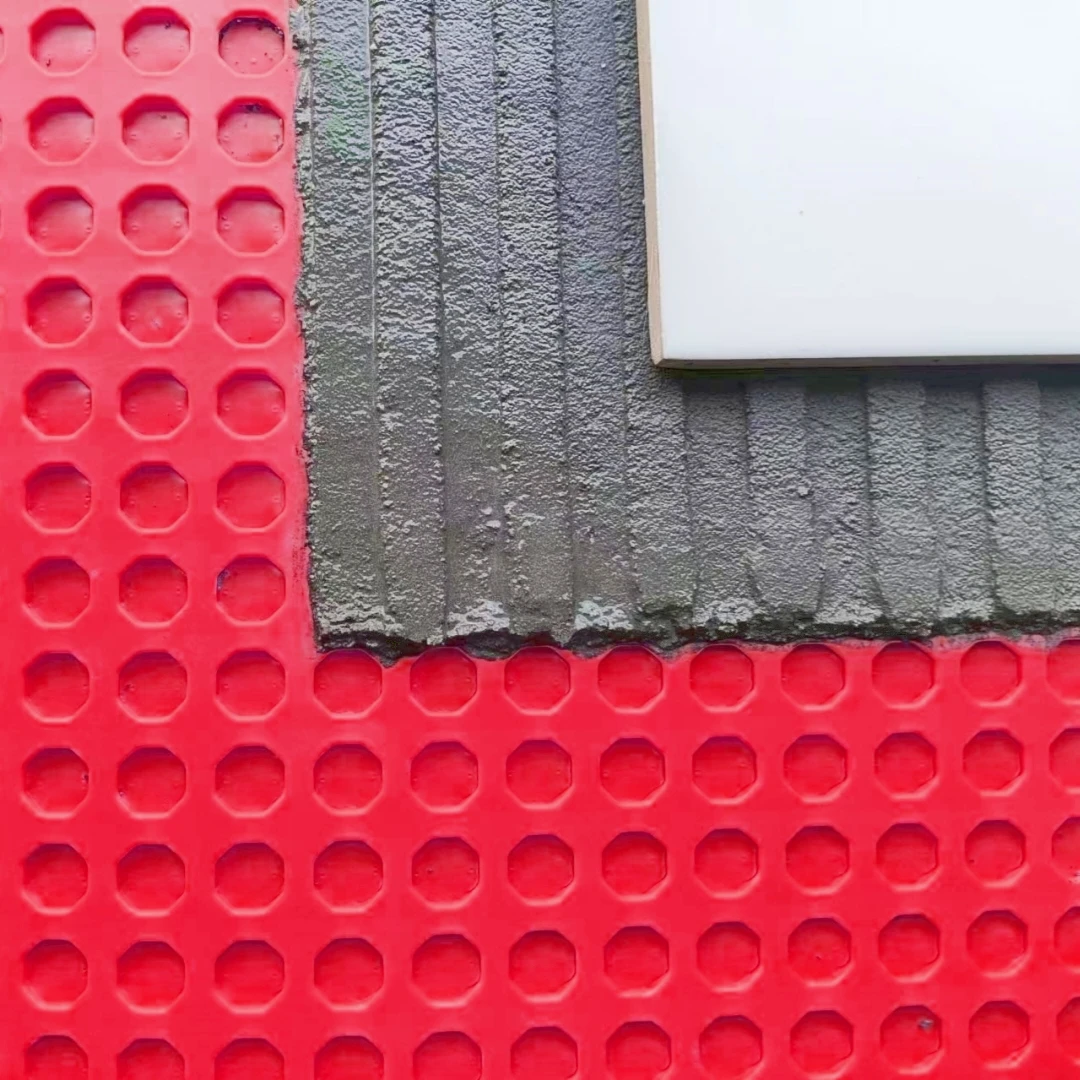

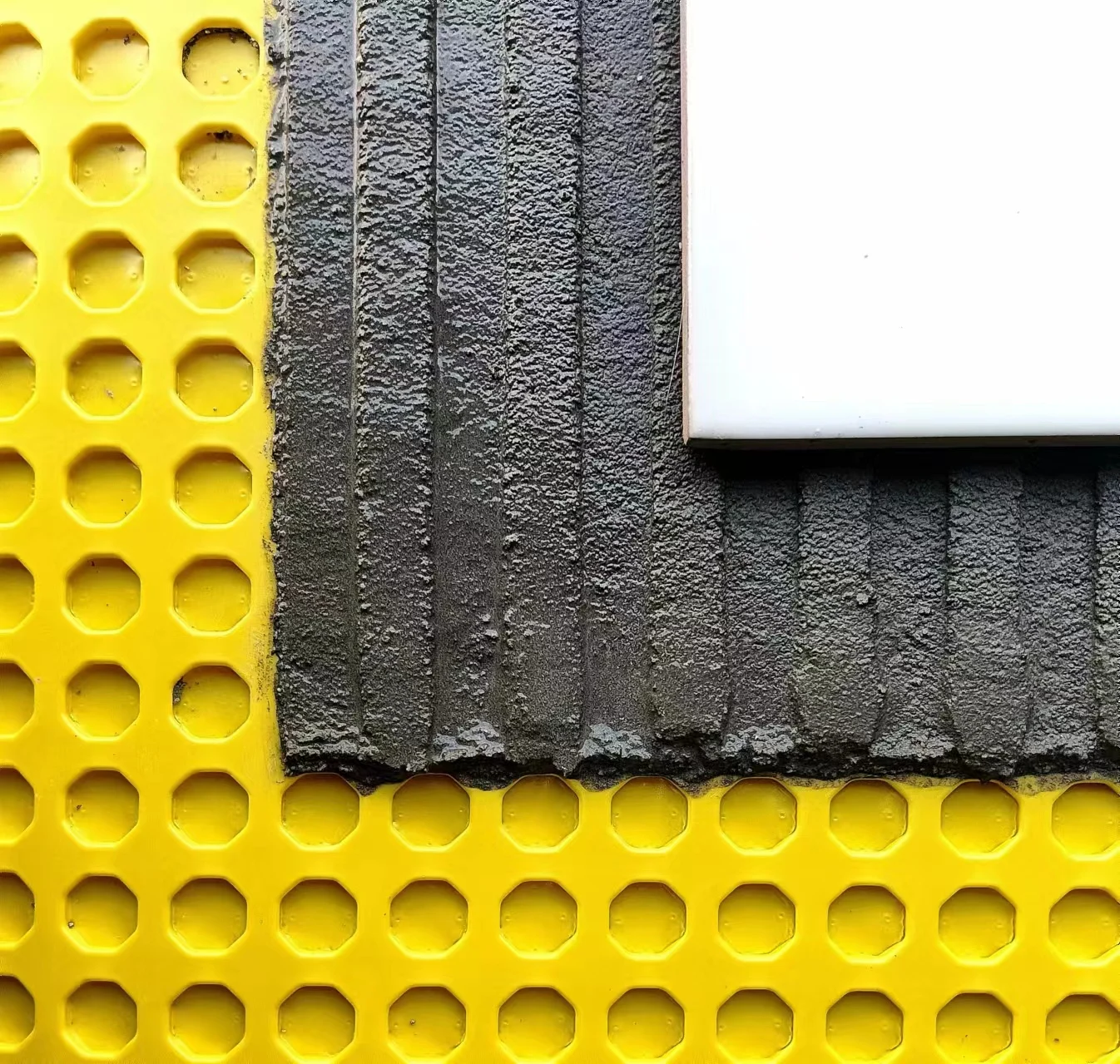

TYCO decoupling membrane is made by polyethylene, with a grid structure of square cavities, each cut back in a dovetail configuration. It is a disconnecting solution that provides an unobtrusive protective layer to avoid potential cracks and maintain a waterproof seal.

Reduce tensions created by changes in the substrate to protect against cracks; suitable for both indoor and outdoor areas.

And here is two types, one only for tiles, one for heating wire.

TYCO decoupling membrane

Features:

- Quick and easy installation

- Maximum protection for tiling

- Ideal for new build and renovation projects

- Protects tiling against cracking

- High shear elasticity

Application & Substrates:

- Suitable for installation in damp and wet rooms, indoors and outdoors.

- Processing within 24 months from date of shipment.

- Concrete Screed (Anhydrite)

- Calcium Sulphate Screed

- Heating Screed

- Poured Asphalt

- Concrete

- Resin and Coated Floors

- Chipboards and Pressed Sheets

- Wooden Floors

- Quick and easy installation

- Maximum protection for tiling

- Ideal for new build and renovation projects

- Protects tiling against cracking

- High shear elasticity

Application & Substrates:

- Suitable for installation in damp and wet rooms, indoors and outdoors.

- Processing within 24 months from date of shipment.

- Concrete Screed (Anhydrite)

- Calcium Sulphate Screed

- Heating Screed

- Poured Asphalt

- Concrete

- Resin and Coated Floors

- Chipboards and Pressed Sheets

- Wooden Floors

Specification

Product | TYCO tile decoupling membrane |

Material | polyethylene(PE)film; polypropylene (PP) nonwoven |

Roll Size | 1x10m, 1x20m, 1x30m etc |

Weight | 600~700g/sqm |

Thickness | approx 3mm |

Packing | wrapped in plastic film |

Color | yellow, red, blue, white, etc |

Why use TYCO decoupling membrane

The use of uncoupling membranes has become more common in recent years due to the variety of problems that it can overcome. There are many different types of uncoupling membranes available which either have added features or should be used for certain situations so it is always important to speak to the supplier before commencing.

Problem 1 – Shrinkage/expansion of a substrate

Newly-laid screeds and concrete contain relatively large amounts of water and as this evaporates, the screed will shrink to

compensate for the resulting volume loss.All substrates will shrink and expand naturally due to humidity and/or temperature

fluctuation.

Any movement, whether shrinkage or expansion will cause stresses to form between the substrate and the tiling layer as both move at a different rate. These stresses either fracture or delaminate the tiles.

compensate for the resulting volume loss.All substrates will shrink and expand naturally due to humidity and/or temperature

fluctuation.

Any movement, whether shrinkage or expansion will cause stresses to form between the substrate and the tiling layer as both move at a different rate. These stresses either fracture or delaminate the tiles.

Problem 2 – Protecting water-sensitive substrates

Nearly all substrates are affected by water in some way but certain substrates such as plaster, anhydrite or plasterboard will

lose nearly all its cohesive strength if it gets wet.

lose nearly all its cohesive strength if it gets wet.

Most wooden substrates, when wet, will expand/ warp causing large stresses to form between the substrate and the tile, which can

cause tiles to fracture or delaminate. Wooden substrates will also become weak and rot if continually wet.

cause tiles to fracture or delaminate. Wooden substrates will also become weak and rot if continually wet.

Problem 3 – Difficult substrates

Certain substrates can be very difficult to reliably tile in a conventional manner. Existing asphalt contains oils which make it

very hard to adhere to whilst metal substrates are very smooth allowing virtually no mechanical key.

very hard to adhere to whilst metal substrates are very smooth allowing virtually no mechanical key.

Installation Instructions

Stage 1: Preparation

The substrate must be clean and free from dust, grease etc. Any irregularities in the surface should be corrected so that the surface is level and without voids. Existing old asphalt should be lightly sanded to roughen the surface and then

vacuumed to remove as much dust as possible. The membrane should be spread out on the floor, cut to size (allow expansion joints at perimeter) and then rolled back up.

Stage 2: Application of an uncoupling membrane

One layer of flexible tile adhesive should be combed onto the substrate using a 3 x 3mm notched trowel. The membrane should then

be pressed into the adhesive bed using a rubber float in the direction the membrane is being laid to prevent air pockets forming.

Adjoining sheets should be carefully abutted. All existing movement joints must be followed through the substrate and tiling

layer.

be pressed into the adhesive bed using a rubber float in the direction the membrane is being laid to prevent air pockets forming.

Adjoining sheets should be carefully abutted. All existing movement joints must be followed through the substrate and tiling

layer.

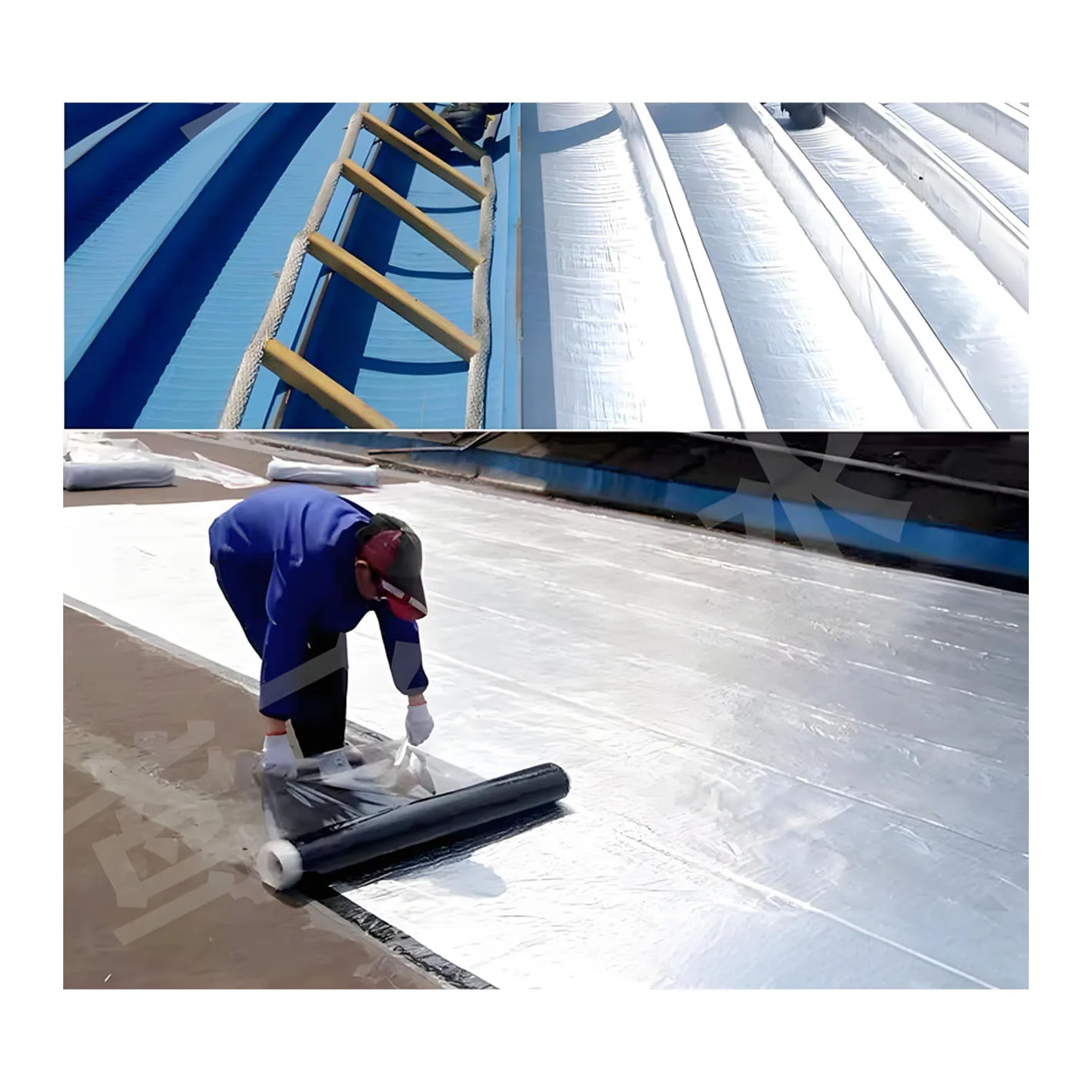

Stage 3: Waterproofing

If the membrane is also to be used as a waterproofing layer, the joints between sheets, perimeter joints and movement joints need

to be sealed. Spread a thin layer of flexible tile adhesive across the joints and then bed a flexible layer of membrane into the

adhesive. The membrane must overlap the joint by at least 50mm. For perimeter joints, the same method applies but care must be

taken not to fill the movement joints at the edge of the sheets with adhesive.

to be sealed. Spread a thin layer of flexible tile adhesive across the joints and then bed a flexible layer of membrane into the

adhesive. The membrane must overlap the joint by at least 50mm. For perimeter joints, the same method applies but care must be

taken not to fill the movement joints at the edge of the sheets with adhesive.

Stage 4: Fixing the tiles

Fix the tiles into a solid bed of flexible tile adhesive. If the uncoupling membrane has cavities, fill these first with the flat

edge of a trowel before spreading adhesive onto the membrane with a notched trowel. Grout the tiles with flexible wall and floor

tile grout or weberjoint pro and use acetic curing silicone sealant to fill perimeter movement joints.

edge of a trowel before spreading adhesive onto the membrane with a notched trowel. Grout the tiles with flexible wall and floor

tile grout or weberjoint pro and use acetic curing silicone sealant to fill perimeter movement joints.

Who We Are

Certificate

Related Product

Welcome to click pictures to see more our hot selling products.

Underfloor Heating Panel

1. Many type for different floors or budget2. OEM size for different project

3. Same to humans and environment

4. Good thermal transfer performance

5. Quality approved by CE/SINTEF/REACH/SGS

3. Same to humans and environment

4. Good thermal transfer performance

5. Quality approved by CE/SINTEF/REACH/SGS

XPS Shower Tray

1. One SQM hold at least 45tons2. OEM&ODM support, open hole to your need

3. Round or linear drains

4. Size from 900mm to 1800mm

5. Quality approved by CE/SINTEF/REACH/SGS

3. Round or linear drains

4. Size from 900mm to 1800mm

5. Quality approved by CE/SINTEF/REACH/SGS

FAQ

Q: Are you manufacturer or trading company?

Q: Your shower niche size is not availbale for my purpose, can you do specific size for me?

A: Sure, OEM and ODM is supportive, we can make specific size and design to fit your floor very well.

A: We are manufacturer over 20years and we export to whole world over 10years.

Q: How does your factory control quality?

A: We do quality control from the very beginning of raw material to the end of production. Each

batch of products will be tested with caution before packing and delivery. We have testing equipment and staff in our QC

department.

batch of products will be tested with caution before packing and delivery. We have testing equipment and staff in our QC

department.

Q: Your shower niche size is not availbale for my purpose, can you do specific size for me?

A: Sure, OEM and ODM is supportive, we can make specific size and design to fit your floor very well.

Q: Can I get samples before ordering?

A: Yes, small size sample is free, and express fee need to be bear in your side.

Q: How about MOQ and delivery?

A: Here is no MOQ if we have enough stock of standard board.

Delivery time will be 15~20days for LCL order(less than full containerload), and 30days for FCL order(full of container load).

Q: Do you support to door delivery service?

A: Yes, we can handle whole delivery service to your door, and first please notice us if you have personal or company tile which can be used for customs clearance after goods arrive destination seaport.

A: Yes, small size sample is free, and express fee need to be bear in your side.

Q: How about MOQ and delivery?

A: Here is no MOQ if we have enough stock of standard board.

Delivery time will be 15~20days for LCL order(less than full containerload), and 30days for FCL order(full of container load).

Q: Do you support to door delivery service?

A: Yes, we can handle whole delivery service to your door, and first please notice us if you have personal or company tile which can be used for customs clearance after goods arrive destination seaport.

Welcome to send us inquiry to get more help!

For urgent need, welcome to send email directly to daisy@hztyco.com or by Whatsapp +86 18868804103

We Recommend

New Arrivals

New products from manufacturers at wholesale prices