Full Pneumatic Stencil Cleaning Machine for Pcba Board cleaning machine CD 750 SMT Stencil cleaning machine

- Category: >>>

- Supplier: Changdian (shenzhen) Automation Equipment Co. Ltd.

Share on (1601143512741):

Product Overview

Description

Products Description

Machine features:

1. Completely using compressed air as energy, no electricity, there is no fire risk.

2. Closed loop cleaning: there will be no gas, liquid leakage; Help to improve the working environment.

3. The CD-750S can clean two boards at the same time and operate independently without interference.

4. High precision 3-stage filtration system: effectively extend the life of cleaning agent recycling.

5. Specially used for cleaning SMT steel mesh, PCB misprint plate and printing machine scraper.

6. The equipment adopts precision filtration system.

7. Cleaning + air drying process to ensure cleanliness.

8. The liquid pressure can be displayed by the hydraulic gauge on the operating panel.

9. Independent exhaust device design makes liquid consumption lower.

10. The whole body is made of 304 stainless steel material, which is durable and resistant to acid and alkaline cleaning fluids.

11. One-click operation, easy to complete the cleaning and air drying work.

12. The whole stainless steel structure, processed by wire drawing process; Beautiful, durable, more convenient maintenance.

13. All pneumatic parts of the equipment are imported original parts; For example: pneumatic diaphragm pump, Pneumatic timer, air source indicator light, pressure regulator filter, etc.; Make the equipment durable and quality guaranteed.

3. The CD-750S can clean two boards at the same time and operate independently without interference.

4. High precision 3-stage filtration system: effectively extend the life of cleaning agent recycling.

5. Specially used for cleaning SMT steel mesh, PCB misprint plate and printing machine scraper.

6. The equipment adopts precision filtration system.

7. Cleaning + air drying process to ensure cleanliness.

8. The liquid pressure can be displayed by the hydraulic gauge on the operating panel.

9. Independent exhaust device design makes liquid consumption lower.

10. The whole body is made of 304 stainless steel material, which is durable and resistant to acid and alkaline cleaning fluids.

11. One-click operation, easy to complete the cleaning and air drying work.

12. The whole stainless steel structure, processed by wire drawing process; Beautiful, durable, more convenient maintenance.

13. All pneumatic parts of the equipment are imported original parts; For example: pneumatic diaphragm pump, Pneumatic timer, air source indicator light, pressure regulator filter, etc.; Make the equipment durable and quality guaranteed.

Item | CD-750 | CD-750S |

Applicable steel mesh size | L1600/750*W750"H40(mm) (big size needs to be customized) | L750"W750*H40(mm) (big size needs to be customized) |

Number of stencils | 1 piece | 2 piece |

Cleaning fluid capacity | 40L(Max) | 45L(Max) |

Optimal liquid usage | 30L | 35L |

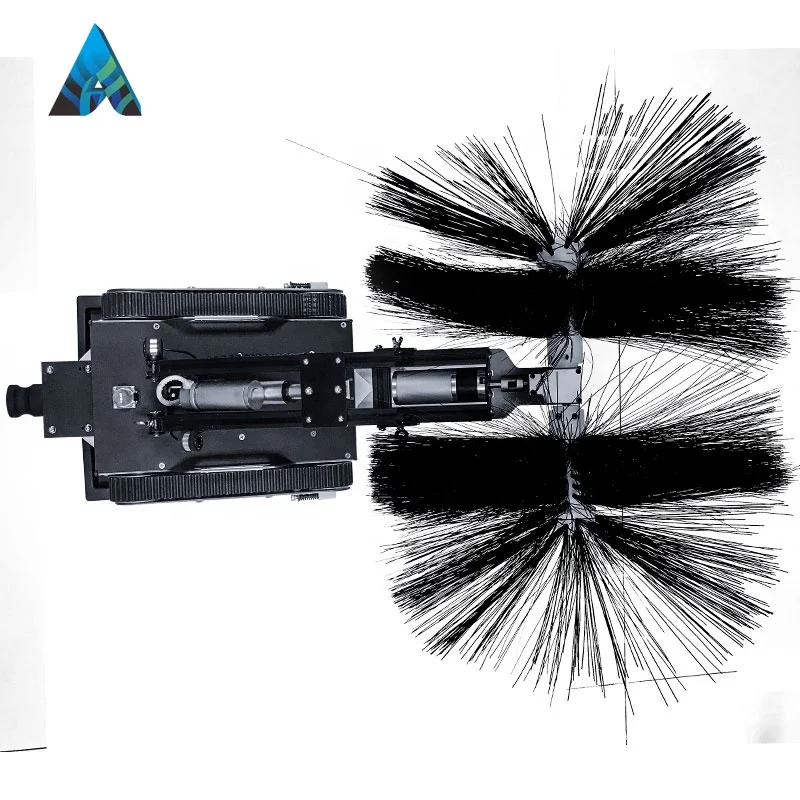

Cleaning method | 360° rotary dean fuid jet and high pressure airjet(clean→dry) | 360° rotary dean fuid jet and high pressure airjet(clean→dry) |

Cleaning time | 2~5 minutes (conventional process) | 2~5 minutes (conventional process) |

Drying time | 2~5 minutes (conventional process) | 2~5 minutes (conventional process) |

External air source | 0.45mpa~0.7mpa | 0.45mpa~0.7mpa |

Tin slag filtering method | Adopt three-stage filtration | Adopt three-stage filtration |

Level 1 filtration | 10 microns(filter impurities and labels) | 10 microns(filter impurities and labels) |

Level 2 filtration | 5 microns (filter small particles and solder paste) | 5 microns (filter small particles and solder paste) |

Level 3 filtration | 1 micron (filter small partidles and rosin) | 1 micron (filter small partidles and rosin) |

Exhaust port size | φ120*25H(mm) | φ120*25H(mm) |

Machine net weigh | 200KG | 350KG |

Machine size | L945*W650*1650(mm) | L1020*W1490*H1730(mm) |

Product Details

Application

Main Products

Company Profile

Packaging & Shipping

FAQ

Q: Do you accept customization?

A: Yes! We can provide customized packaging, logo and size.

Q: What's the MOQ?

A: 1 set, One-on-one service, meeting different product requirements.

Q: What' s the delivery time of your products?

A: Delivery time depending on your purchasing quantity and production season.

Available in stock for 1-5 days, customized for 15-20 days.

Q: How does your factory do regarding quality control?

A: Quality is priority. we will do 100% quality inspection before shipment.

Q: What is your terms of payment?

A: We Accept T/T.

For mass production: 30% deposit before mass production,70% before shipment.

Q: Can we use our own logo and design?

A: Yes, you can. We'll according to your request to put you logo or design.

For logo file must AI file.

Q: When can l get the price?

A: We usually quote within 24 hours after we get your inquiry.

If you are very urgent to get the price, please call us or contact through Trade Manager to get prompt response. please call us or

tell us in your email so that we will regard your inquiry priority.

A: Yes! We can provide customized packaging, logo and size.

Q: What's the MOQ?

A: 1 set, One-on-one service, meeting different product requirements.

Q: What' s the delivery time of your products?

A: Delivery time depending on your purchasing quantity and production season.

Available in stock for 1-5 days, customized for 15-20 days.

Q: How does your factory do regarding quality control?

A: Quality is priority. we will do 100% quality inspection before shipment.

Q: What is your terms of payment?

A: We Accept T/T.

For mass production: 30% deposit before mass production,70% before shipment.

Q: Can we use our own logo and design?

A: Yes, you can. We'll according to your request to put you logo or design.

For logo file must AI file.

Q: When can l get the price?

A: We usually quote within 24 hours after we get your inquiry.

If you are very urgent to get the price, please call us or contact through Trade Manager to get prompt response. please call us or

tell us in your email so that we will regard your inquiry priority.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices