CNC Customized Mechanical Keyboard 60% TKL KYUU WK WKL High Quality Aluminum Keyboard With Brass Weight

- Category: >>>

- Supplier: Shenzhen Strongd Model Technology Co. Ltd.Shenzhen Ltd.

Share on (1601151080703):

Product Overview

Description

Product Description

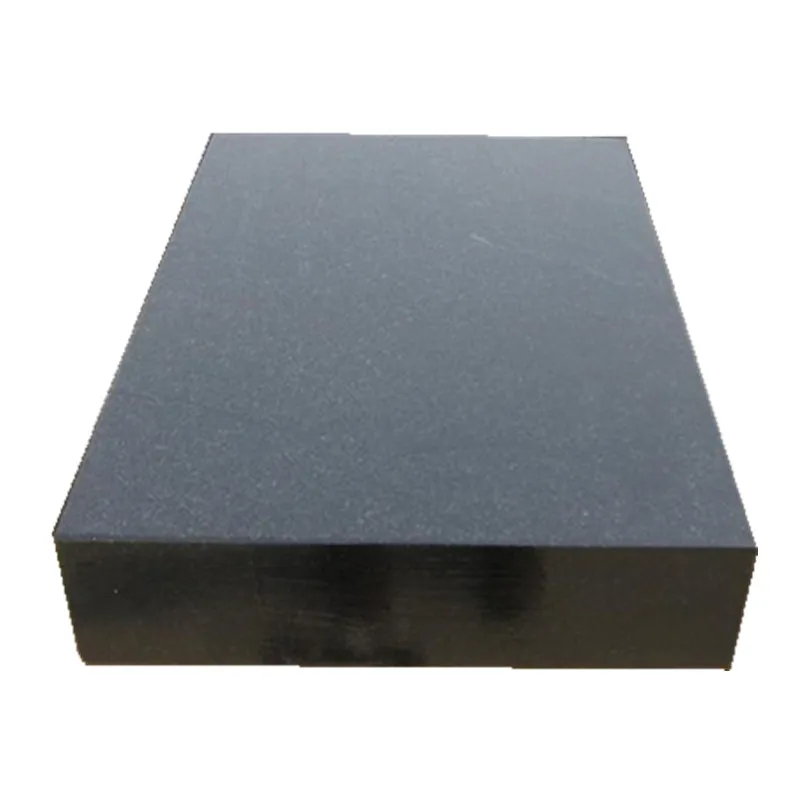

CNC Milling Aluminium Mechanical Keyboard Case/Plate/Top /Bottom

Surface Treatment:Sand Blasting/Anodizing Aluminum/HardAnodizing/Powder Coating/Chroming/Polishing/Brushing ect.

Conventional Material

Top and Bottom : Aluminum/Stainless steel

Plate: Aluminum /Brass / Stainless steel / Copper/ POM.

Conventional Material

Top and Bottom : Aluminum/Stainless steel

Plate: Aluminum /Brass / Stainless steel / Copper/ POM.

CNC Copper Parts

Material: Brass/Bronze/Cooper

Surface Finish: Polishing/Plating/Brashing

Material: Brass/Bronze/Cooper

Surface Finish: Polishing/Plating/Brashing

CNC Aluminum Parts

Surface Treatment:Sand Blasting/Anodizing Aluminum/Hard Anodizing/Powder Coating/Chroming/Polishing/Brushing ect.

Conventional Material:AL 6061(T6), AL 6062(T6), AL 6063(T6), AL 6013(T6), AL 7075(T6), AL 5052.

Surface Treatment:Sand Blasting/Anodizing Aluminum/Hard Anodizing/Powder Coating/Chroming/Polishing/Brushing ect.

Conventional Material:AL 6061(T6), AL 6062(T6), AL 6063(T6), AL 6013(T6), AL 7075(T6), AL 5052.

Steel and Iron Parts

4140 / 4130 / 4340 A2 Tool Steel

SUS 304 SUS303 SS 316 440C Stainless steel

Surface Finish: Polishing/PowderCoating/Galvanized/Chroming/Electropolishing/Plating/

4140 / 4130 / 4340 A2 Tool Steel

SUS 304 SUS303 SS 316 440C Stainless steel

Surface Finish: Polishing/PowderCoating/Galvanized/Chroming/Electropolishing/Plating/

Blackening

Specification

item | value |

CNC Machining or Not | Cnc Machining |

Type | Broaching, DRILLING, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

Micro Machining or Not | Micro Machining |

Material | Stainless Steel,Brass, Aluminum |

Process | CNC Turning CNC Milling |

Product name | Professional Precision Cnc Machining Parts |

Surface treatment | Painting,Plating, Powder coating, Anodized |

Service | Customized OEM |

Application | Industrial Equipment |

Equipment | CNC Machining Centres |

Keyword | CNC Macining Parts |

Color | Customized Color |

Drawing Format | STP. STEP . IGS . PRT . X_T |

Company Profile

Welcome to Shenzhen Strongd Model Technology Co., Ltd.

Shenzhen Strongd Model Technology Co., Ltd. is a professional rapid prototype making company, founded in 2011. Strongd combines conventional modeling methods with the latest edge -cutting technologies to provide customized rapid prototype making solutions for each client.

We offer a variety of comprehensive services, including CNC, SLA, SLS and 3D printing. And we are professional in all kinds of metal and plastic rapid prototyping, small lot production, heat forming, mold design, as well as high precision post machining. Meanwhile, we have close cooperation with numerous excellent companies in different industries, we could provide you with efficient and reliable technical support and solution.

After 10 years developing, we have various clients from different industries including medical, telecom, automobile, consumer, industrial and many other fields. They are mainly in China, the United States, Europe, East Africa and Southeast Asia.

If you are looking for a rapid prototype, our company is your reliable partner to deliver what you want to build efficiently. We do strive to help you to bring each good idea to become prototype.

I am in charge of the Sales and Marketing Department of overseas market. Please don't hesitate to send us inquiry. Hope we could work together very soon.![]()

Shenzhen Strongd Model Technology Co., Ltd. is a professional rapid prototype making company, founded in 2011. Strongd combines conventional modeling methods with the latest edge -cutting technologies to provide customized rapid prototype making solutions for each client.

We offer a variety of comprehensive services, including CNC, SLA, SLS and 3D printing. And we are professional in all kinds of metal and plastic rapid prototyping, small lot production, heat forming, mold design, as well as high precision post machining. Meanwhile, we have close cooperation with numerous excellent companies in different industries, we could provide you with efficient and reliable technical support and solution.

After 10 years developing, we have various clients from different industries including medical, telecom, automobile, consumer, industrial and many other fields. They are mainly in China, the United States, Europe, East Africa and Southeast Asia.

If you are looking for a rapid prototype, our company is your reliable partner to deliver what you want to build efficiently. We do strive to help you to bring each good idea to become prototype.

I am in charge of the Sales and Marketing Department of overseas market. Please don't hesitate to send us inquiry. Hope we could work together very soon.

Contact: Jennie He

Mobile Phone and We-chat: 86 17607616852

E-mail: jennie@szstrongd.com

Exhibition Room

Where we display the products we've made under the authorization of our clients

Where we display the products we've made under the authorization of our clients

Our Workshop (This is Strongd CNC Machining Center )

CNC milling and turning : prototype and mass production

Available materials : Aluminum, Stainless steel, Iron, copper, Brass, Plastic etc...

Drawing Format: step, x_t, igs, stp, prt, sldprt.

Tolerance : +/- 0.01 mm ( metal parts) +/- 0.05 mm (Plastic parts)

Available materials : Aluminum, Stainless steel, Iron, copper, Brass, Plastic etc...

Drawing Format: step, x_t, igs, stp, prt, sldprt.

Tolerance : +/- 0.01 mm ( metal parts) +/- 0.05 mm (Plastic parts)

Vacuum Casting Workshop

Step 1 - Make master patterns using SLA/ SLS base on 3d drawing.

Step 2 - Pour liquid silicone around the master pattern in a casting box

Step 3 - Cure it in an over for 16 hours ( vacuum process -bake-cool)

Step 4 - Cut the mold open and remove the master part

Step 5 - Empty cavity in the exact shape as the original

Step 6 - Pour the casting resins and make exact copies of original

Low Volume Production work 2-1000 pieces, save the cost.

Step 1 - Make master patterns using SLA/ SLS base on 3d drawing.

Step 2 - Pour liquid silicone around the master pattern in a casting box

Step 3 - Cure it in an over for 16 hours ( vacuum process -bake-cool)

Step 4 - Cut the mold open and remove the master part

Step 5 - Empty cavity in the exact shape as the original

Step 6 - Pour the casting resins and make exact copies of original

Low Volume Production work 2-1000 pieces, save the cost.

Injection Molding Workshop

Plastic injection molding work for mass production

Certification (ISO 9001)

" cooperation,creativity ,customer first " is the principle of people in Strongd,we insist profession and honesty can bring customers closer to us and only by the trust & supporting from customers can we go farther and stronger.

Packing & Delivery

Usually packed in carton or wooden box after wrapping carefully by foam.

Or as per the customers' requires.

Or as per the customers' requires.

FAQ

Q: How long is your delivery time?

A: Generally it is 3-5 days, it should be according to quantity.

Q: What is your terms of payment ?

A: 50% deposit before arranging production, the balance should be paid before delivery.

Q:How will you ship the products to me?

A: We will make a best plan to ship the products as per its size and material. We generally use DHL / FeDeX / UPS/ EMS.

Q: Is it possible to know how is my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: If you make poor quality goods,will you refund our fund?

A: As a matter of fact, we won't take a chance to make poor quality products. Meanwhile, we manufacture good quality products until reach your satisfaction.

A: Generally it is 3-5 days, it should be according to quantity.

Q: What is your terms of payment ?

A: 50% deposit before arranging production, the balance should be paid before delivery.

Q:How will you ship the products to me?

A: We will make a best plan to ship the products as per its size and material. We generally use DHL / FeDeX / UPS/ EMS.

Q: Is it possible to know how is my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: If you make poor quality goods,will you refund our fund?

A: As a matter of fact, we won't take a chance to make poor quality products. Meanwhile, we manufacture good quality products until reach your satisfaction.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices