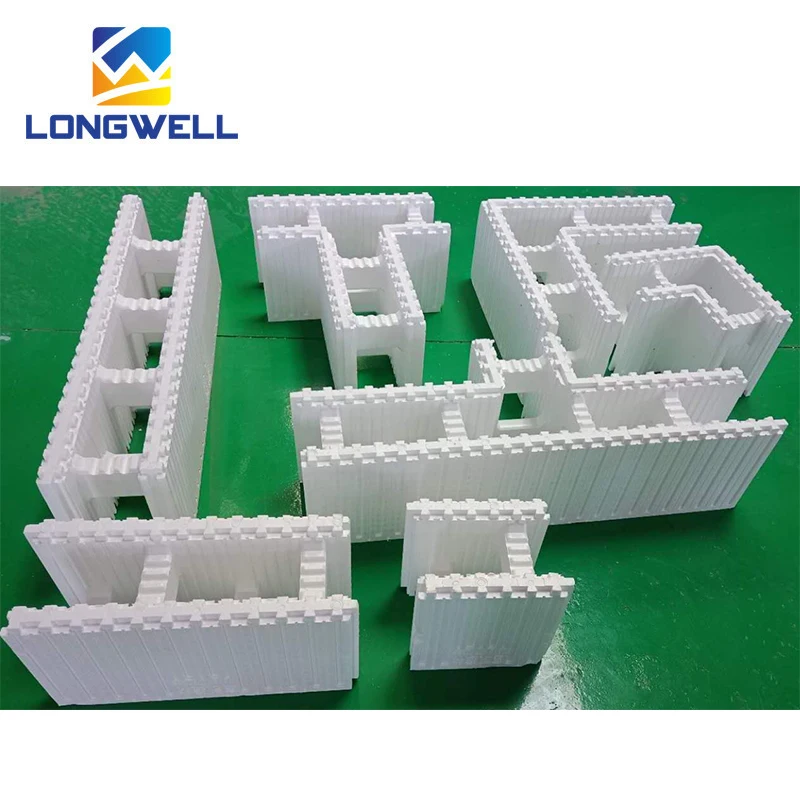

Custom EPS ICF Molds for Innovative Building Solutions

- Category: >>>

- Supplier: Hangzhou Fuyang Longwell Industry Co. Ltd.Hangzhou Ltd.

Share on (1601154168761):

Product Overview

Description

Product Name | Mold for EPS shape molding machine |

Material | High quality 6063 aluminum alloy |

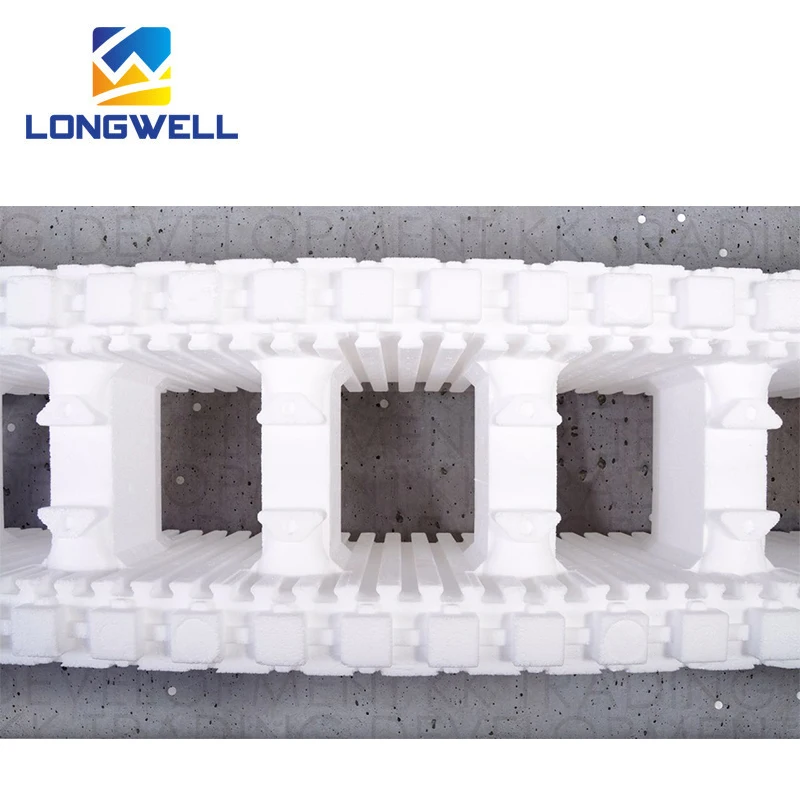

Application | EPS Packaging Box. Styrofoam Icf Blocks, Decoration Cornice and other EPS Productions |

Package | Wooden Case Packaging |

MOQ | 1 set |

Finished Prodcution | Customized |

Service | Convert customer's samples to CAD drawing or 3D drawings, test mould before delivery |

2. EPS mold are processed by CNC machines, mould sizes are precise.

3. All cavities and cores are covered by Teflon coating to guarantee easy demoulding.

2. Our engineer have rich experience to make designs.

3. We can convert customer's samples to CAD drawing or 3D drawings.

Hangzhou Fuyang Longwell Industry Co.,Ltd has focused on top quality EPS machines & relevant equipment, With 20 years' experience in EPS industry.

Longwell Industry insist on cooperating with customers, offers one-stop services, including factory checking, machines selection, production arrangement, production tracking, before-delivery inspection, load-container checking, document confirmation and after-sales service. Timely report is given to clients for all details. so as to improve working efficiency, competitiveness and realize mutual benefits.

EPS pre-expander

1. Full automatic and continuous production.

2. Controlled by touch screen and PLC, easy to operate.

3. High output and save energy.

4. Stable quality and less.

EPS shape machine

1. Controlled by PLC and touch screen, easy to operate.

2. With vacuum system creates fast product molding and cooling, while decreasing water content.

3. With multiple de-molding device, it can handle any difficult to de-mold product.

EPS block machine

1. All block mold frames are treated by heat-treatment to ensure strength.

2. Taiwan original hydraulic station and all good quality parts.

EPS mould system

1. Made of high quality aluminum material, and mould frame is made by extruded aluminum alloy profile, strong and long lasting.

2.Processed by CNC machines, mould sizes are precise.

3. All cavities and cores coated by Teflon.

Production Process: whole advanced processing equipment, every procedure under quality control.

Projects in clients' factories

Q. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance. Other payment terms can also be negotiated.

Q. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q. How about your delivery time?

A: Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q. Can you produce according to the samples?

A: Yes, we can produce mold by your samples or technical drawings.

Q. Do you test all your machines before delivery?

A: Yes, we have 100% test before delivery.

Q. Do you have some videos where we can see the line producing?

A: Yes, we can provide some videos for reference.

Q: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

vicky19862

+86 13758164390

We Recommend

New Arrivals

New products from manufacturers at wholesale prices