2 4micron cu coated metallised copper PET rolls copper clad polyester film for flexible printed circuit board FPCB

- Category: >>>

- Supplier: Shijiazhuang Dajia New Materials Technology Co. Ltd.

Share on (1601155661318):

Product Overview

Description

Products Description

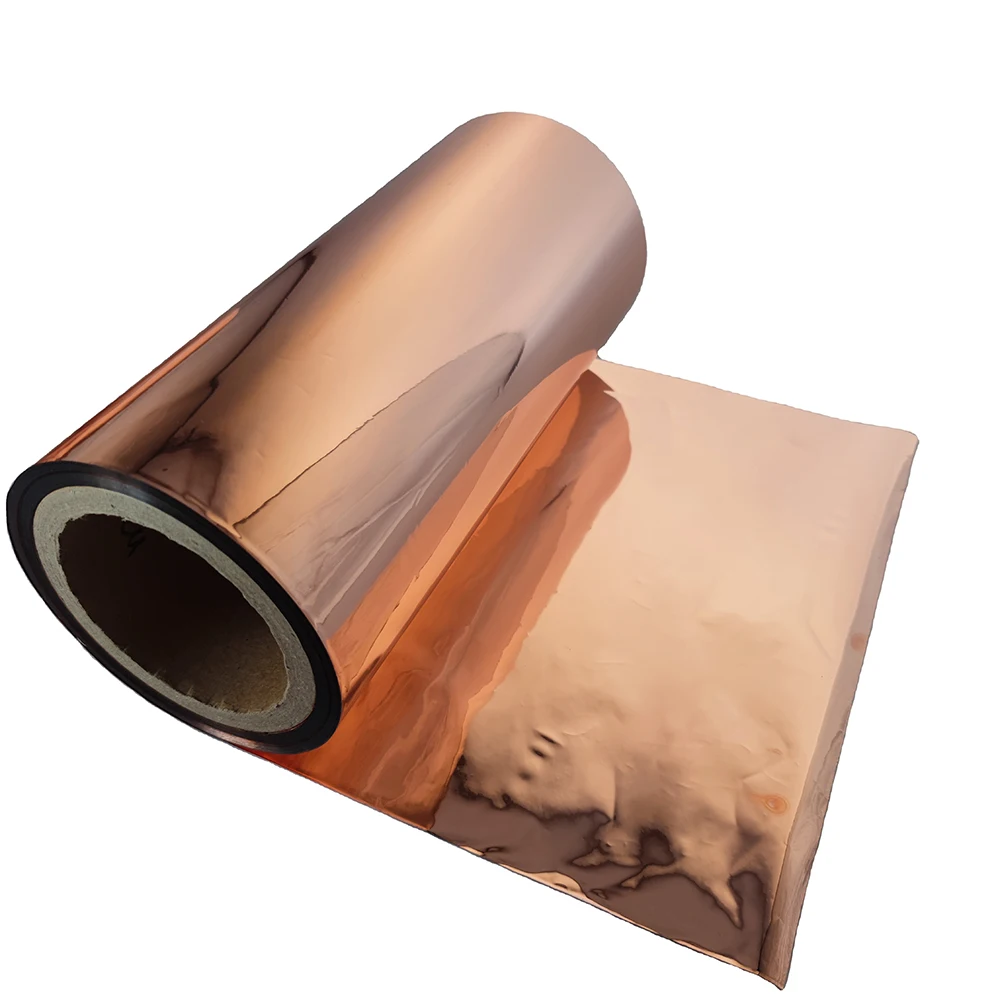

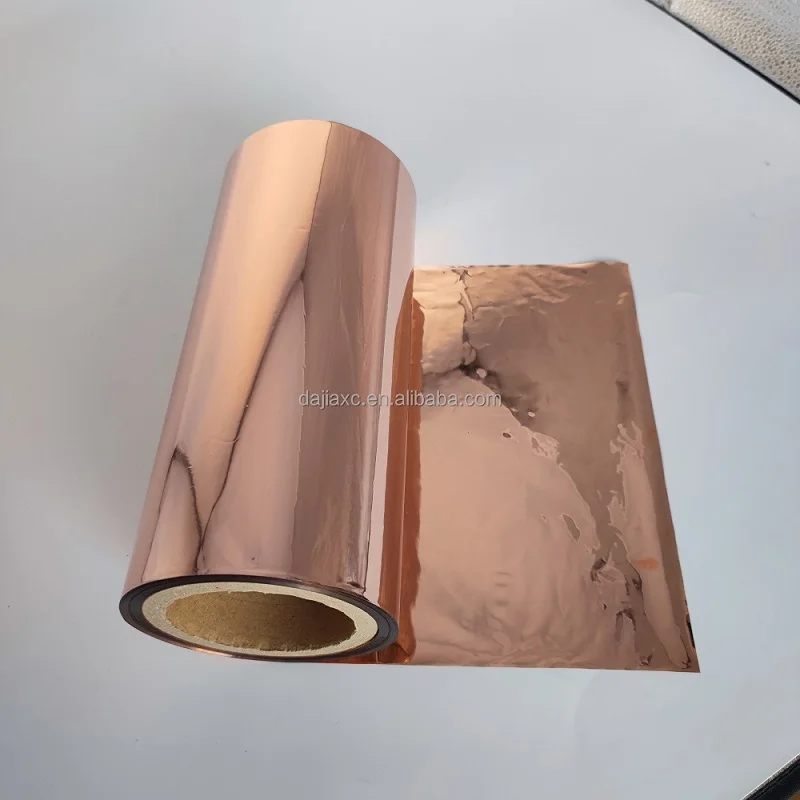

2-4micron cu coated metallised copper PET rolls copper clad polyester film for flexible printed circuit board FPCB

One side or Both sides Copper coated ( both sides brass metalized) Metallized PET film is deposited 99.99% pure copper on the polyester film , while ensuring good mechnical and thermal bonding.The copper coated PET or Polyimide film,the resistivity less than 1 ohm conductive.

Both side Copper and one side copper metallized PET film can be customized ,the copper thickness and base film can be customized .

And copper coated polyester film The thickness of Copper is 3micron , 6micron ect . The Max width of roll is 1300mm.

The Polymide Film have excellent Electrical Insulation and heat resistance.. It can be used for Speaker Voice Coil. Mainly thickness is 7.5micron ,12.5micron .25micron,50um, 75micron , 125micron , 250micron ect This product has high light transparency and heat resistance, and has excellent solvent resistance and mechanical strength.

advantages:

(1) excellent heat resistance.

2) excellent mechanical properties.

(3) good chemical stability and moisture

and heat resistance.

and heat resistance.

(4) good radiation resistance.

(5) good dielectric performance.

Technical Data Sheet

No. | Test Item | Unit | Standard | ||||||||||||

25μm | 30μm | 40μm | 50μm | 75μm | 100μm | ||||||||||

1 | Density | g/cm3 | 1.400±0.020 | ||||||||||||

2 | Tensile Strength | Vertical | MPa | ≥135 | |||||||||||

Horizontal | ≥115 | ||||||||||||||

3 | Elongation ratio | Vertical and Horizontal | % | ≥35 | |||||||||||

4 | Shrinkage 150°C 400°C | % | ≤1.0 ≤3.0 | ||||||||||||

5 | Frequency Electrical Intensity | Average Value | MV/m | ≥150 | ≥130 | ≥110 | |||||||||

Individual Value | ≥100 | ≥80 | ≥70 | ||||||||||||

6 | Surface Resistivity (200°C) | Ω | ≥1.0X1013 | ||||||||||||

7 | Volume Resistivity (200°C) | Ω·M | ≥1.0X1010 | ||||||||||||

8 | Relative Dielectric Constant 48-62Hz | 3.5±0.4 | |||||||||||||

9 | Dielectric Loss Factor 48-62Hz | ≤4.0X10-3 | |||||||||||||

10 | Long-term Heat-Resistance Temperature Index | ≤180 | |||||||||||||

Images Shows

both sides brass metalized Polyimide film

Application

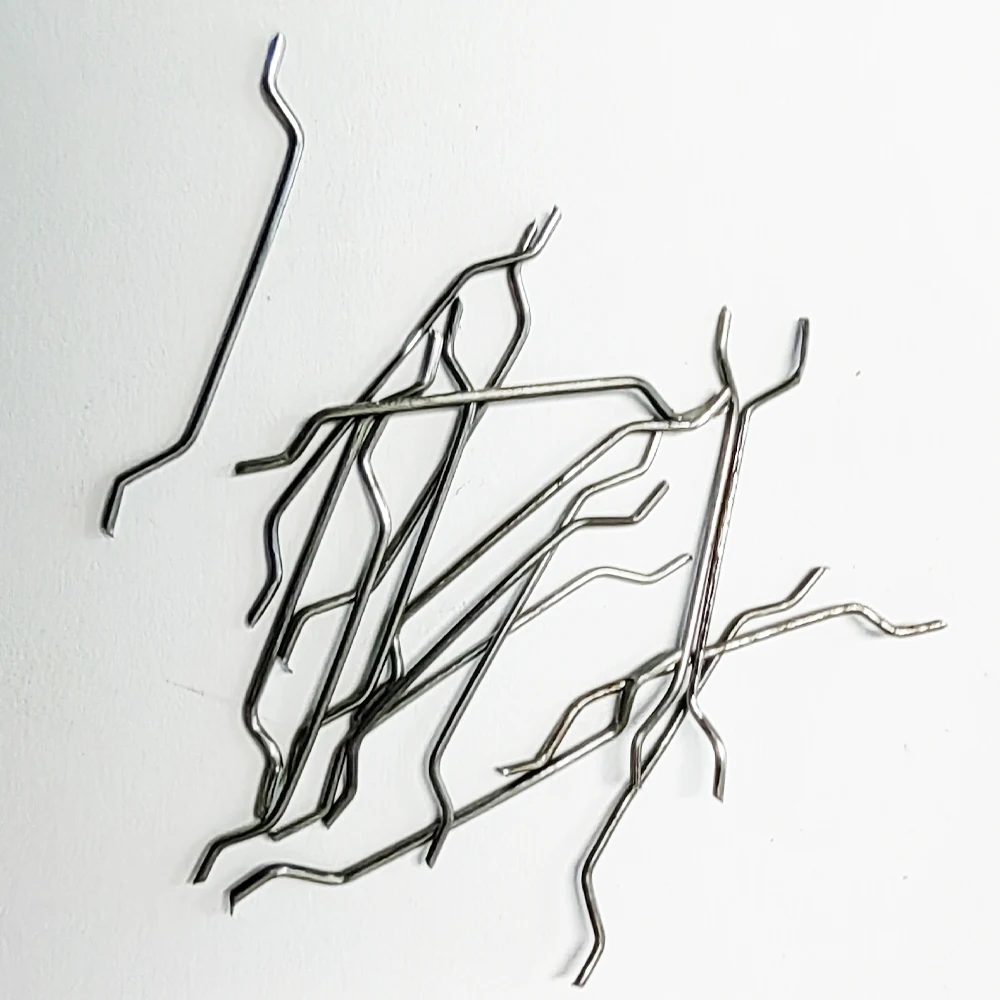

The Polyimide film Mainly used for Electrical and Electronics, circuit board manufacture H grade electric engine, transformer coil and capacitor insulation wrapping up in high-temperature, high-voltage condition SMT thermal resistance, protection of PCB board.High temperature resistance and waterproof for electronic transformer etc.

Packaging and Delivery

Company Profile

Established in June 2014, Shijiazhuang Dajia New Material Technology Co., Ltd. is a high-tech enterprise integrating R&D,experimental processing and production. The company has been focusing on the R&D, production, sales and after-sales service of plastic film new materials for many years, and its rapid production capacity and complete differentiated product structure can meet the various needs of customers in different regions.

Our products are divided into eight categories: general PET film series, PET color film series, PET functional film series, PET deep processing film series, PI high temperature film series, PET and PI derived film series, fluorine film weathering resistance film series, and perforated film series.

Our products are divided into eight categories: general PET film series, PET color film series, PET functional film series, PET deep processing film series, PI high temperature film series, PET and PI derived film series, fluorine film weathering resistance film series, and perforated film series.

Certifications

Payment and Delivery

Contact us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices