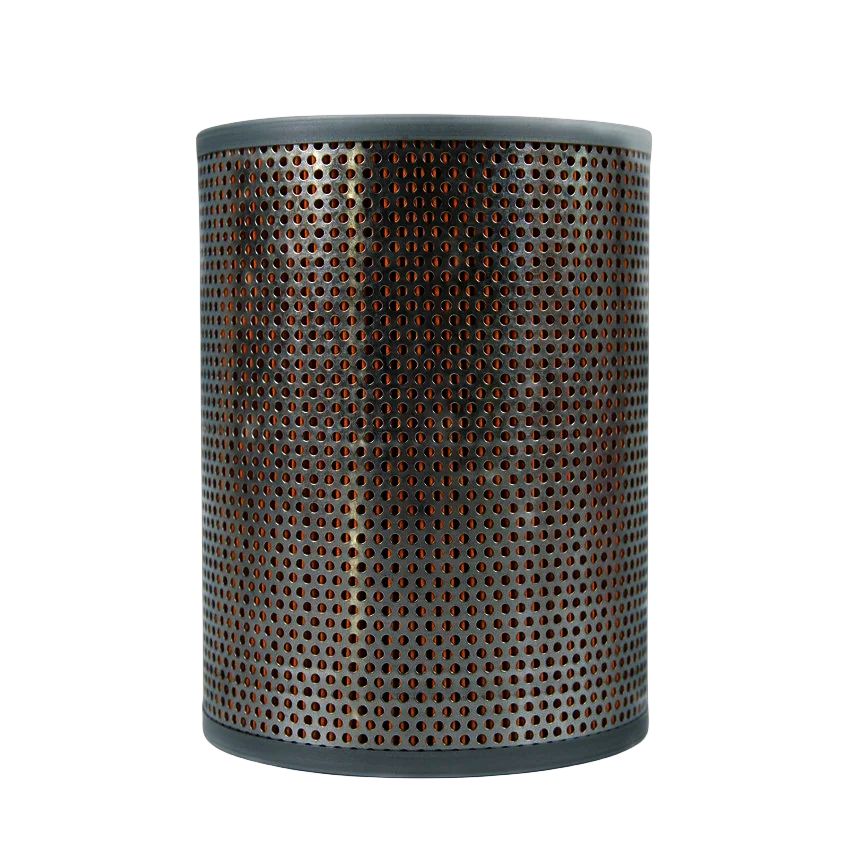

Automatic Backwash Self cleaning Filter Housing hot sale for industry factory filtration

- Category: >>>

- Supplier: Qingdao Crowns Machinery Co. Ltd.Qingdao Ltd.

Share on (1601158019032):

Product Overview

Description

Filtration Stage

The medium flows through the filter element either from inside to outside or from outside to inside. Here the dirt particles are retained and the cleaned medium reaches the filter outlet. When the differential pressure reaches a certain value, a signal is transmitted from the differential pressure indicator to the control unit, which automatically triggers the backwashing process.

Backflushing Phase

When the differential pressure reaches a certain value, the differential pressure indicator transmits a signal to the control

system, which automatically triggers the backwashing process. During backflush, the dirt particles are flushed off of the

filtration surface by filtered fluid reversal of flow (own medium or through an external flush medium, compressed air, or service water).

The medium flows through the filter element either from inside to outside or from outside to inside. Here the dirt particles are retained and the cleaned medium reaches the filter outlet. When the differential pressure reaches a certain value, a signal is transmitted from the differential pressure indicator to the control unit, which automatically triggers the backwashing process.

Backflushing Phase

When the differential pressure reaches a certain value, the differential pressure indicator transmits a signal to the control

system, which automatically triggers the backwashing process. During backflush, the dirt particles are flushed off of the

filtration surface by filtered fluid reversal of flow (own medium or through an external flush medium, compressed air, or service water).

Working pressure | ≤0.8MPa |

temperature | ≤100℃ |

accuracy(Micron) | 30-300 |

Flange Connection | According to relevant standards |

Note | size,accuracy,pressure, temperature can be customed |

With advanced production equipment, strong R&Dability, and testing equipment all at high state of readiness, Crownwig can satisfy a variety ofprofessionally customized requirements.

After years of unremitting efforts, the company has won high praise from its customers regardingits strict quality management and high-quality after-sales service, the well-known large customersaccounting for up to 95%.

Crownwig assists customers to win a lot of government bidding proiectstogether .

After years of unremitting efforts, the company has won high praise from its customers regardingits strict quality management and high-quality after-sales service, the well-known large customersaccounting for up to 95%.

Crownwig assists customers to win a lot of government bidding proiectstogether .

Q1 : Where is your factory located?

A1 : Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

Q2 : Are you an integrated supplier for industrial filter machine ?

A2 : Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3 : How about the quality control in your factory?

A3 : Qingdao crowns has the SOP (Standard Operation Procedure) and all the production step must follow

up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully

before shipment.

Q4 : Will you offer the pre-sales service?

A4 : Yes, we have an experienced pre-sales team to support customers not only including machine, technology

also water electrical,machine layout in factory, etc.

Q5 : What about the after-service? Will you send your engineer to my country to help commission and install the

machine?

A5 : Surely, we have many experience technical engineers for oversea service, they would help you install machine

and support training to workers also.

Q6 : What is the delivery time of the machine?

A6 : Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery

time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7 : The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8 : Yes, CROWNS will provide one set standard spare parts to customer according to different machines

A1 : Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

Q2 : Are you an integrated supplier for industrial filter machine ?

A2 : Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3 : How about the quality control in your factory?

A3 : Qingdao crowns has the SOP (Standard Operation Procedure) and all the production step must follow

up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully

before shipment.

Q4 : Will you offer the pre-sales service?

A4 : Yes, we have an experienced pre-sales team to support customers not only including machine, technology

also water electrical,machine layout in factory, etc.

Q5 : What about the after-service? Will you send your engineer to my country to help commission and install the

machine?

A5 : Surely, we have many experience technical engineers for oversea service, they would help you install machine

and support training to workers also.

Q6 : What is the delivery time of the machine?

A6 : Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery

time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7 : The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8 : Yes, CROWNS will provide one set standard spare parts to customer according to different machines

We Recommend

New Arrivals

New products from manufacturers at wholesale prices