surface treatment equipment used for the treatment of oil stains covers of closed steel drums drum degreasing equipment

- Category: >>>

- Supplier: Dezhou Congtai Mechanical Electrical Equpment Co. Ltd.

Share on (1601161147206):

Product Overview

Description

brief introduction

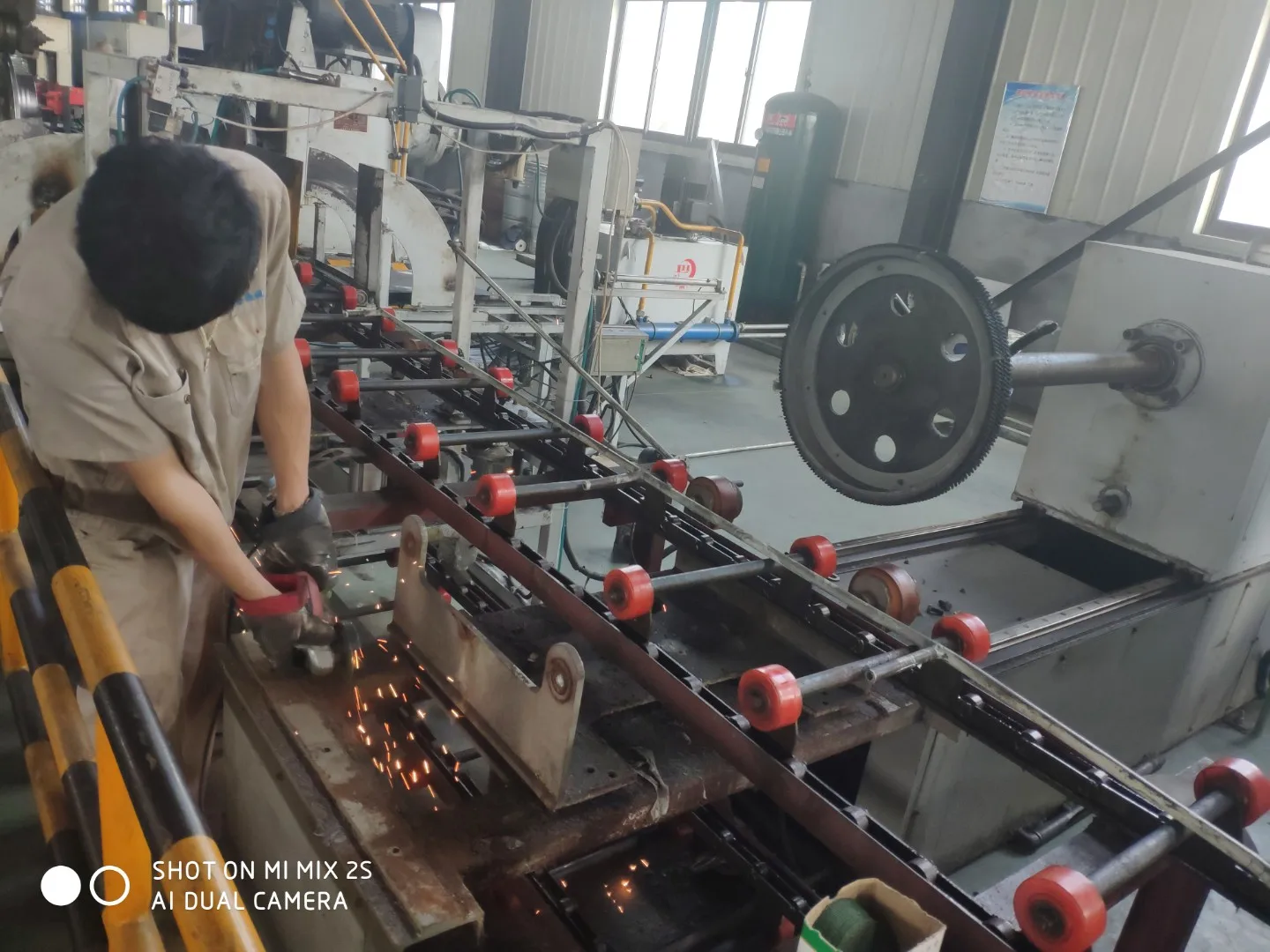

Fully automatic single-double station wipping machine

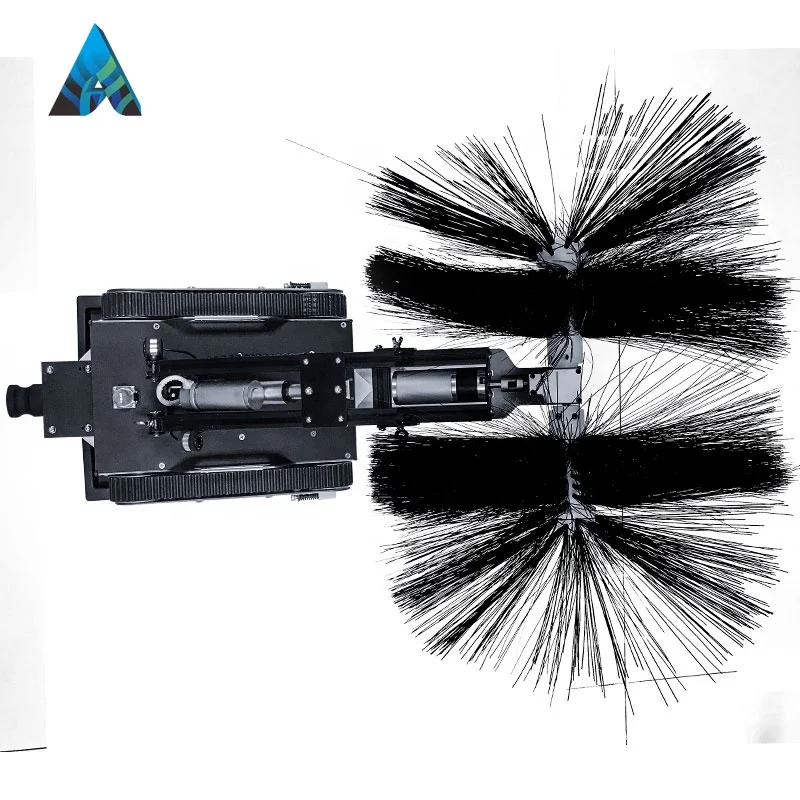

Our company has been exploring the bottleneck process in the barrel making industry for a long time, and through the unremitting efforts of researchers for more than half a year, we have developed the latest patented equipment, a fully automatic single row double wiping cap machine, through multiple experiments and upgrades; Patent number: 201620059620.7 This device fills a gap in the dust treatment of the inner wall of high-definition buckets on the production line of the barrel making industry. Currently at the forefront of the industry. Mainly used for the treatment of oil stains on the inner surface and stretching parts of the upper and lower covers of closed steel drums, it can automatically spray oil remover, and the working time of each time period can be set independently. The time interval for fabric collection and release can be set independently, and the fabric collection roll can be quickly disassembled. During the wiping process, it can automatically blow away any dust that has been wiped off. Realize full automation and programming. This device has a small footprint and is flexible and mobile, allowing for easy movement and use on the site without any restrictions. Due to its high efficiency, 1-2 people are required to feed or receive materials during use. The number of wiping covers per hour is about 500 or more, and the speed is adjustable. It can also be used in the middle section line. A single machine can be equipped with an automatic capping machine, and one person can load without receiving materials. The capping machine is fully automatic, with a height of 1.4 meters. Easy to operate, convenient for maintenance and adjustment. The wiped bucket lid is clean and tidy. Greatly improving product quality, increasing product competitiveness, saving manpower, reducing energy consumption costs, and achieving no emissions are truly environmentally friendly treatment equipment. It is an essential specialized equipment for current barrel making enterprises.

Selling points | It can automatically spray oil remover, and the working time of each time period can be set independently. The time interval for fabric collection and release can be set independently, and the fabric collection roll can be quickly disassembled. |

function | The number of wiping covers per hour is about 500 or more, and the speed is adjustable, which can also be used in the middle section line. A single machine can be equipped with an automatic capping machine, and one person can load without receiving materials. The capping machine is fully automatic, with a height of 1.4 meters. |

Electrical part | It consists of a program controller (PLC), motor, frequency converter, touch screen, sensor connection and connecting cables, etc.Equipped with PLC controllers produced by Mitsubishi Corporation, imported from Japan, for central control. Choose the top domestic motor brand "Hengshui Mengniu" motor as the power source. Parameter modification is controlled on the MCGS touch screen. |

Pneumatic part | It consists of a shut-off valve, a water separation filter, an oil mist collector, a pressure regulating valve, an electromagnetic air valve, an atomizing nozzle, a blowing and sweeping blade nozzle, pipelines, etc. |

Company Profile

Our company is a leading manufacturer of drum cleaning equipment, specializing in providing sustainable and environmentally friendly alternatives to traditional acid pickling and phosphating processes.

Driven by a commitment to excellence and a vision for a greener future, we have developed a range of cutting-edge drum cleaning solutions that revolutionize the surface treatment industry. Our equipment is designed to efficiently clean and prepare drums without relying on harmful acids or phosphates, thus reducing environmental impact and enhancing worker safety.

Our team of engineers and experts is dedicated to the continuous research and development of innovative technologies.

Our drum cleaning equipment factory stands at the forefront of green technology, specializing in the development and production of environmentally friendly cleaning solutions. We firmly believe that in modern industrial production, environmental protection is not just a responsibility but also a competitive edge. Therefore, we are committed to replacing traditional acid pickling and phosphating processes with innovative drum cleaning equipment.

One of the key advantages of our drum cleaning equipment is its complete elimination of harmful acids and phosphates. Instead, we employ advanced physical and chemical cleaning techniques that effectively sanitize drums without generating toxic wastewater and emissions. This significantly reduces the environmental burden and lowers the cost of waste treatment for our clients.

Whether it's for industrial production lines or smaller-scale operations, our machines are tailored to meet the specific needs of our clients.

At our company, we believe in the power of partnership and strive to build long-lasting relationships with our clients. We pride ourselves on our exceptional customer service, providing timely support and solutions to ensure smooth operation and maximum satisfaction.

Moreover, we prioritize the use of environmentally friendly materials and energy-efficient

As a factory with a strong sense of social responsibility, we integrate environmental protection into every aspect of our operations. We firmly believe that only by embracing green development can we achieve sustainable business growth and harmonious coexistence with society.

As a factory with a strong sense of social responsibility, we integrate environmental protection into every aspect of our operations. We firmly believe that only by embracing green development can we achieve sustainable business growth and harmonious coexistence with society.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices