CAN GAS factory sales price PSA Nitrogen Generator working with hydrogen generator together to make green ammonia power to X

- Category: >>>

- Supplier: CAN GAS SYSTEMS COMPANY LIMITED

Share on (1601162268265):

Product Overview

Description

Product Description

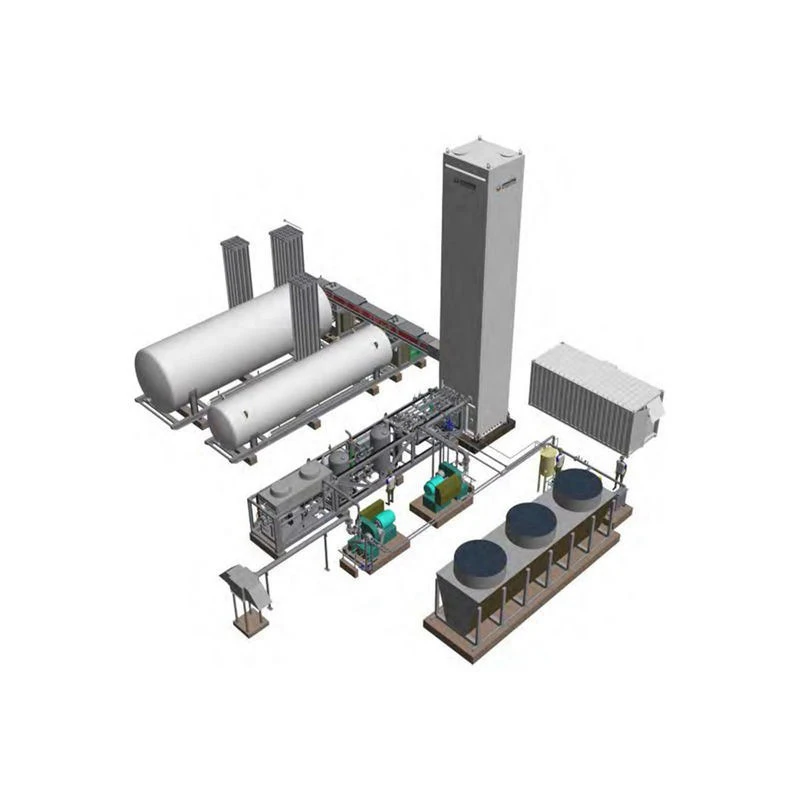

CAN GAS CAPN /CAPN HP series PSA Nitrogen Gas Generator

CANGAS PSA( pressure swing adsorption) on-site nitrogen generator -product gas technical indicators:

Nitrogen flow rate:5-8000Nm3/h

Nitrogen purity: ≥97%~99.9995%

Nitrogen dew point:-20~-80℃

Nitrogen outlet pressure: 0.2~1.0Mpa (adjustable)

CANGAS PSA nitrogen production equipment is divided into: 95%,97%, 98%, 99%, 99.5%, 99.9%, 99.99%, 99.995%, 99.999%,99.9995

according to nitrogen purity, for your choice.

Nitrogen Generator type: PSA N2 generator , Membrane nitrogen generator , Skid mounted type ,small box type ,container type, trailer type, truck type .

CANGAS PSA( pressure swing adsorption) on-site nitrogen generator -product gas technical indicators:

Nitrogen flow rate:5-8000Nm3/h

Nitrogen purity: ≥97%~99.9995%

Nitrogen dew point:-20~-80℃

Nitrogen outlet pressure: 0.2~1.0Mpa (adjustable)

CANGAS PSA nitrogen production equipment is divided into: 95%,97%, 98%, 99%, 99.5%, 99.9%, 99.99%, 99.995%, 99.999%,99.9995

according to nitrogen purity, for your choice.

Nitrogen Generator type: PSA N2 generator , Membrane nitrogen generator , Skid mounted type ,small box type ,container type, trailer type, truck type .

Green ammonia power to X

Ammonia is produced in vast quantities worldwide for agricultural fertilisers but uses natural gas or other fossil fuels to

provide both the hydrogen feedstock and the energy to power the synthesis process. As a result, ammonia production by these methods releases almost 1.5% of global CO₂ emissions.

The demonstrator shows that not only could this process be used to dramatically reduce emissions from the current production methods, but that ammonia can also be a practical hydrogen energy vector, further reducing CO₂ emissions by allowing for storage at scale.

Ammonia can be used as a practical hydrogen energy vector and its pre-existing industry which already produces, stores, and trades millions of tonnes of ammonia every year, means the infrastructure already exists to kick-start the hydrogen economy.

Powered by green hydrogen, which is hydrogen produced by renewable power, the system converted hydrogen back into electricity to charge the electric vehicles in the supercar paddock. This shows that electric vehicle charging around the world can be delivered in this way, making a drastic impact on reducing harmful emissions and driving the uptake of electric vehicles.

One of the most important challenges today is the decarbonization of the gobal economy. The key to meeting this challenge is to consistently expand renewable energy sources as well as the concept of sector coupling, meaning to integrate renewables in developed industry, energy, and mobility infrastructures with Power-to-X solutions using green hydrogen.

Climate change is now the biggest challenge that humanity has ever faced. With the global population growing and the use of fossil resources continuing to drive global warming, the problem needs to be solved. We need to provide both food and energy to the world's growing population, and do so sustainably. To stop climate change we have developed technologies that make sustainability feasible for businesses, reduce the carbon footprint of industrial value chains, and accelerate the growth of renewable energy.

This is exactly what motivated us to develop our green ammonia technology ‑ perfect not only for building new green ammonia plants but also for greening up existing plants by means of a revamp.

Green ammonia applications - an astounding potential!

Ammonia is ideal for shipping green hydrogen and green energy across the globe. Why?

* Ammonia has a higher volumetric energy density than hydrogen, which requires high compression and extensive cooling.

* Ammonia is already being traded and transported in large quantities (around 20 million t/year) worldwide, global standards for safe handling practices have been established and the infrastructure is in place.

* Ammonia cannot only be used as an energy carrier to transport hydrogen to where it is needed, but also as an emission-free marine fuel to power the ships or as a fuel for direct combustion in turbines.

provide both the hydrogen feedstock and the energy to power the synthesis process. As a result, ammonia production by these methods releases almost 1.5% of global CO₂ emissions.

The demonstrator shows that not only could this process be used to dramatically reduce emissions from the current production methods, but that ammonia can also be a practical hydrogen energy vector, further reducing CO₂ emissions by allowing for storage at scale.

Ammonia can be used as a practical hydrogen energy vector and its pre-existing industry which already produces, stores, and trades millions of tonnes of ammonia every year, means the infrastructure already exists to kick-start the hydrogen economy.

Powered by green hydrogen, which is hydrogen produced by renewable power, the system converted hydrogen back into electricity to charge the electric vehicles in the supercar paddock. This shows that electric vehicle charging around the world can be delivered in this way, making a drastic impact on reducing harmful emissions and driving the uptake of electric vehicles.

One of the most important challenges today is the decarbonization of the gobal economy. The key to meeting this challenge is to consistently expand renewable energy sources as well as the concept of sector coupling, meaning to integrate renewables in developed industry, energy, and mobility infrastructures with Power-to-X solutions using green hydrogen.

Climate change is now the biggest challenge that humanity has ever faced. With the global population growing and the use of fossil resources continuing to drive global warming, the problem needs to be solved. We need to provide both food and energy to the world's growing population, and do so sustainably. To stop climate change we have developed technologies that make sustainability feasible for businesses, reduce the carbon footprint of industrial value chains, and accelerate the growth of renewable energy.

This is exactly what motivated us to develop our green ammonia technology ‑ perfect not only for building new green ammonia plants but also for greening up existing plants by means of a revamp.

Green ammonia applications - an astounding potential!

Ammonia is ideal for shipping green hydrogen and green energy across the globe. Why?

* Ammonia has a higher volumetric energy density than hydrogen, which requires high compression and extensive cooling.

* Ammonia is already being traded and transported in large quantities (around 20 million t/year) worldwide, global standards for safe handling practices have been established and the infrastructure is in place.

* Ammonia cannot only be used as an energy carrier to transport hydrogen to where it is needed, but also as an emission-free marine fuel to power the ships or as a fuel for direct combustion in turbines.

Working Principle

How to select nitrogen generator

Tell CAN GAS purity/ pressure/ flow rate needed in your application, our professional sales team will help you .

Host model | Extended model | Purity(%) | 99.999 | 99.995 | 99.99 | 99.9 | 99.5 | |||||||

CAPN HP-2 | CAPN HP-2 | Capacity(Nm³/h) | 1.12 | 1.76 | 2 | / | / | |||||||

Size(mm) | 1120×950×1110 | / | ||||||||||||

Weight(KG) | 397 | |||||||||||||

CAPN HP-2C | Size(mm) | 1200×1100×1150 | ||||||||||||

Weight(KG) | 437 | |||||||||||||

CAPN HP-10 | CAPN HP-10 | Capacity(Nm³/h) | 5.6 | 8.8 | 10 | / | / | |||||||

Size(mm) | 1270×1030×1740 | |||||||||||||

Weight(KG) | 550 | |||||||||||||

CAPN HP-10C | Size(mm) | 1350×1100×1800 | ||||||||||||

Weight(KG) | 600 | |||||||||||||

CAPN HP-35 | CAPN HP-35 | Capacity(Nm³/h) | 19.6 | 30.8 | 35 | 56 | 64.4 | |||||||

Size(mm) | 1600×1450×1950 | |||||||||||||

Weight(KG) | 1400 | |||||||||||||

CAPN HP-35C | Size(mm) | 1700×1550×2000 | ||||||||||||

Weight(KG) | 1450 | |||||||||||||

CAPN HP-80 | CAPN HP-80 | Capacity(Nm³/h) | 44.8 | 80 | 128 | 160 | 192 | |||||||

Size(mm) | 2000×1800×2500 | 1900×1200×2350 | ||||||||||||

Weight(KG) | 2036 | 1614 | ||||||||||||

CAPN HP-80C | Size(mm) | 2100×1900×2600 | / | |||||||||||

Weight(KG) | 2096 | |||||||||||||

The above table shows some models of nitrogen generators, others can be customizable. | ||||||||||||||

Company Profile

We have the largest professional production base of PSA oxygen generators,PSA nitrogen generator,membrane nitrogen

generator,medical on-site oxygen generator etc air seperation system in China since 1998, covers an area of 28,000m2.

1. One of the most experienced manufacturer of air separation Unit(ASU) in China CAN GAS is one of the first air separation technology developing companies in China, dedicated to researching and developing more suitable onsite medical gas solutions for hospitals.

2. Most professional oxygen generator manufacturer in China

(1)Since establishment, R&D and production of ASU is our professional field.

(2)The only company own High-tech enterprise and new tech product/service certificate for medical PSA oxygen generator.

(3)The most patent certificate for medical oxygen generator and software copyright.

(4)Unique company covering business sectors, medical, commercial and artificial environment.

(5)Trusted by customers and distributors

generator,medical on-site oxygen generator etc air seperation system in China since 1998, covers an area of 28,000m2.

1. One of the most experienced manufacturer of air separation Unit(ASU) in China CAN GAS is one of the first air separation technology developing companies in China, dedicated to researching and developing more suitable onsite medical gas solutions for hospitals.

2. Most professional oxygen generator manufacturer in China

(1)Since establishment, R&D and production of ASU is our professional field.

(2)The only company own High-tech enterprise and new tech product/service certificate for medical PSA oxygen generator.

(3)The most patent certificate for medical oxygen generator and software copyright.

(4)Unique company covering business sectors, medical, commercial and artificial environment.

(5)Trusted by customers and distributors

Certifications

References

Service

After service and Warranty:

Warranty: PERIOD of warranty is 18 months after shipment or 12 months after commissioning, whichever occurs first. It is responsible for CANGAS to analysis, answer breakdowns for users all through the working life of CANGAS oxygen generator. Engineer can be sent on-site for free after-service service if necessary. Please refer to Warranty terms for more information.

Installation & Commissioning & Training: CANGAS service engineer is available to instruct the installation and start up of this plant (6 days at job site with service fee or remotely).If job site service is needed the buyer should prepare flights, accommodation, food and local transportation for CANGAS service engineer.

Installation & Commissioning & Training: CANGAS service engineer is available to instruct the installation and start up of this plant (6 days at job site with service fee or remotely).If job site service is needed the buyer should prepare flights, accommodation, food and local transportation for CANGAS service engineer.

Global Exhibition

Customer Photos

We Recommend

Cryogenic air Separation Unit Gas with Two Columns Oxygen Nitrogen Producing Manufacturers

$170,000.00-180,000.00

New Arrivals

New products from manufacturers at wholesale prices