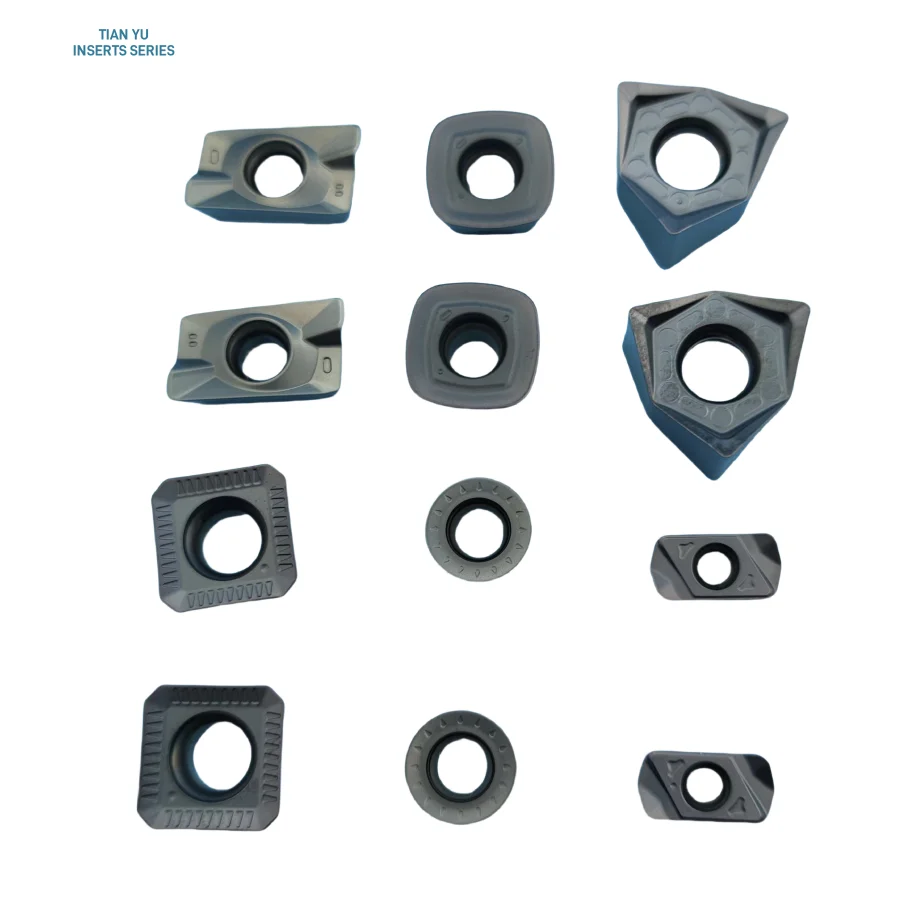

Turning Tool Insert milling Tungsten Carbide Inserts RPMT APMT APKT RPHX CNC Milling Cutter

- Category: >>>

- Supplier: Guangdong Tianyu Mechanical Equipment Co. Ltd.

Share on (1601163058885):

Product Overview

Description

Product Description

Specification

TYPE(820J) | Price (USD) | PRODUCT INFORMATION * Contact the seller for discounts on bulk purchases |

RPMW1003MO | 0.67 | MITSUBISHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

RPMT10T3MOE | 0.67 | Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

RPMT10T3MO-JS | 0.67 | Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

RDMW1204MO | 0.92 | WALTER Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

RPMW1204MO-JS | 0.92 | MITSUBISHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

RDMT1204MOTN(HITACHI) | 0.92 | HITACHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

RCMT1204MO(H) | 0.92 | SANDVIK Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

RCMT1606MO | 1.84 | SANDVIK Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

RDMW1605MO | 1.50 | WALTER Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APMT1135PDER-H2 | 0.75 | MITSUBISHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APMT1135PDER-M2 | 0.75 | MITSUBISHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APMT1604PDER-H2 | 1.00 | MITSUBISHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APMT1604PDER-M2 | 1.00 | MITSUBISHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APMT1135PDER-DL | 0.75 | Duracarb Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APMT1604PDER-DL | 1.17 | Duracarb Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APMT160416PDER-DR | 1.17 | MITSUBISHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APMT160420PDER-HH | 1.17 | MITSUBISHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APMT160430PDER-DR | 1.17 | MITSUBISHI Groove Type Suitable for processing stainless steel, high-temperature alloys, titanium alloys, with good versatility |

APKT1003PDER-820J | 1.34 | ISCAR be applicable Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

APKT11T308-GM-820J | 1.34 | ISCAR be applicable Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

APKT160408-GM-820J | 1.67 | ISCAR be applicable Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

APKT170508R-820J | 1.84 | TaeguTec be applicable Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

APKT170516R-820J | 1.84 | TaeguTec be applicable Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

APKT170524R-820J | 1.84 | TaeguTec be applicable Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

APKT170530R-820J | 1.84 | TaeguTec be applicable Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

RPHX1204M6EN-M31-820J | 1.50 | Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

RPHX1204M6EN-M31-820J-A | 1.67 | Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

RPHX1204M6EN-M31-820JX-A | 1.67 | Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

RPHX1204M6EN-M31-820JY-M | 2.00 | Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

RPHX1204M6EN-M31-820JX-M | 2.00 | Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

BPMT1135PDER-JC-820J | 0.83 | Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

BPMT160408PDER-JC-820J | 1.17 | Suitable for processing stainless steel, steel parts, and hard materials, with good versatility |

RPMW1003MO(F)-820JX-1 | 1.00 | MITSUBISHI Groove Type Suitable for processing below HRC62 Heat treated hard materials and high-temperature alloys, titanium alloys, and stainless steel |

RDMT10T3MOTN-TT EG820JX-1 | 1.00 | HITACHI Groove Type Suitable for processing below HRC62 Heat treated hard materials and high-temperature alloys, titanium alloys, and stainless steel |

RDMW1204MO-DL(F)-820JX-1 | 1.08 | Duracarb Groove TypeSuitable for processing below HRC62 Heat treated hard materials and high-temperature alloys, titanium alloys, and stainless steel |

APMT1135PDER-DL(F)-820JX-1 | 1.00 | Duracarb Groove Type Suitable for processing below HRC62 Heat treated hard materials and high-temperature alloys, titanium alloys, and stainless steel |

APMT1604PDER-DL(F)-820JX-1 | 1.25 | Duracarb Groove Type Suitable for processing below HRC62 Heat treated hard materials and high-temperature alloys, titanium alloys, and stainless steel |

MGGN300-Q-8-J68 | 1.34 | KORLOYGroove Type KORLOYHolder Rod Applicable Suitable for stainless steel and viscous materials |

MGGN400-Q-8-J68 | 1.42 | KORLOYGroove Type KORLOYHolder Rod Applicable Suitable for stainless steel and viscous materials |

MRGN200-R-J68 | 1.17 | KORLOYGroove Type KORLOYHolder Rod Applicable Suitable for stainless steel and viscous materials |

MRGN300-R-J68 | 1.17 | KORLOYGroove Type KORLOYHolder Rod Applicable Suitable for stainless steel and viscous materials |

MRGN400-R-J68 | 1.34 | KORLOYGroove Type KORLOYHolder Rod Applicable Suitable for stainless steel and viscous materials |

MRGN500-R-J68 | 1.67 | KORLOYGroove Type KORLOYHolder Rod Applicable Suitable for stainless steel and viscous materials |

TDC/J-200 (J68) | 1.17 | TaeguTecGroove Type TaeguTecHolder Rod Applicable Suitable for stainless steel and viscous materials |

TDC/J-300 (J68) | 1.25 | TaeguTecGroove Type TaeguTecHolder Rod Applicable Suitable for stainless steel and viscous materials |

TDC/J-400 (J68) | 1.34 | TaeguTecGroove Type TaeguTecHolder Rod Applicable Suitable for stainless steel and viscous materials |

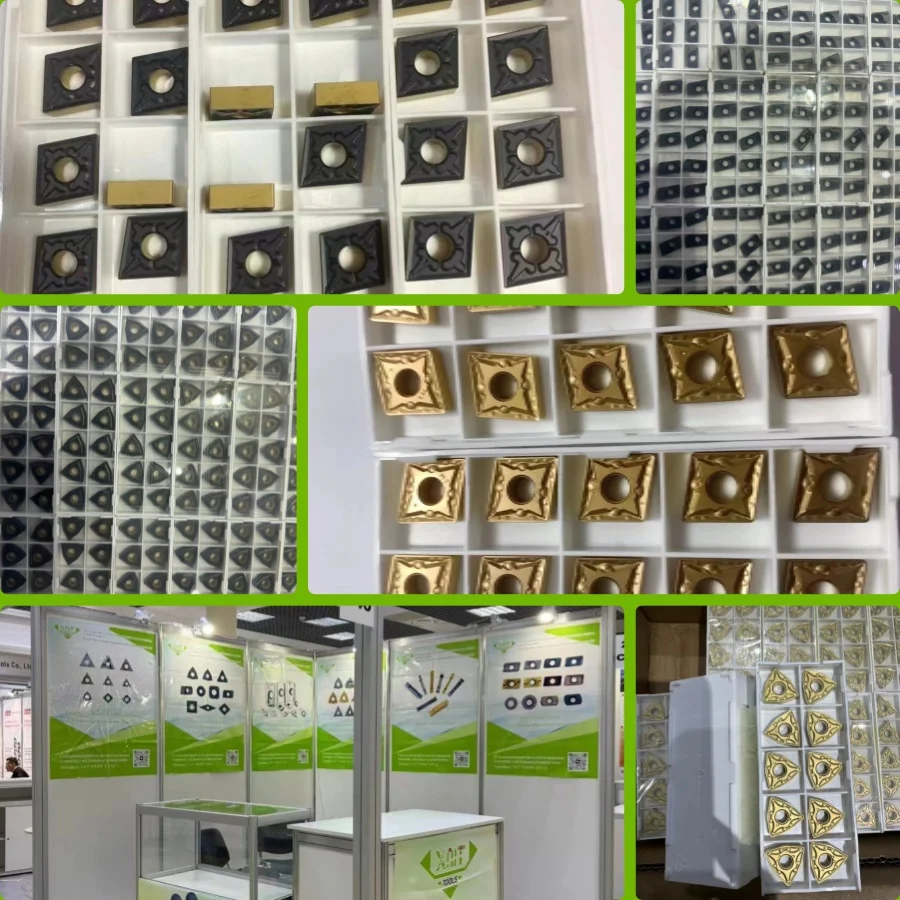

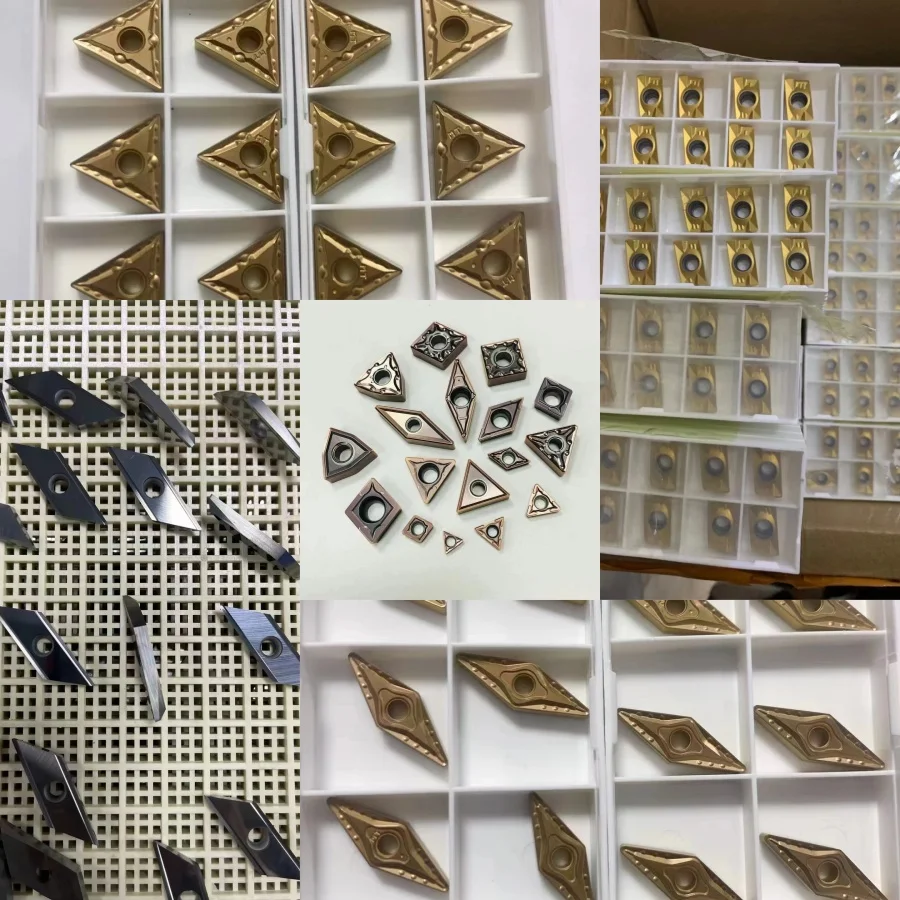

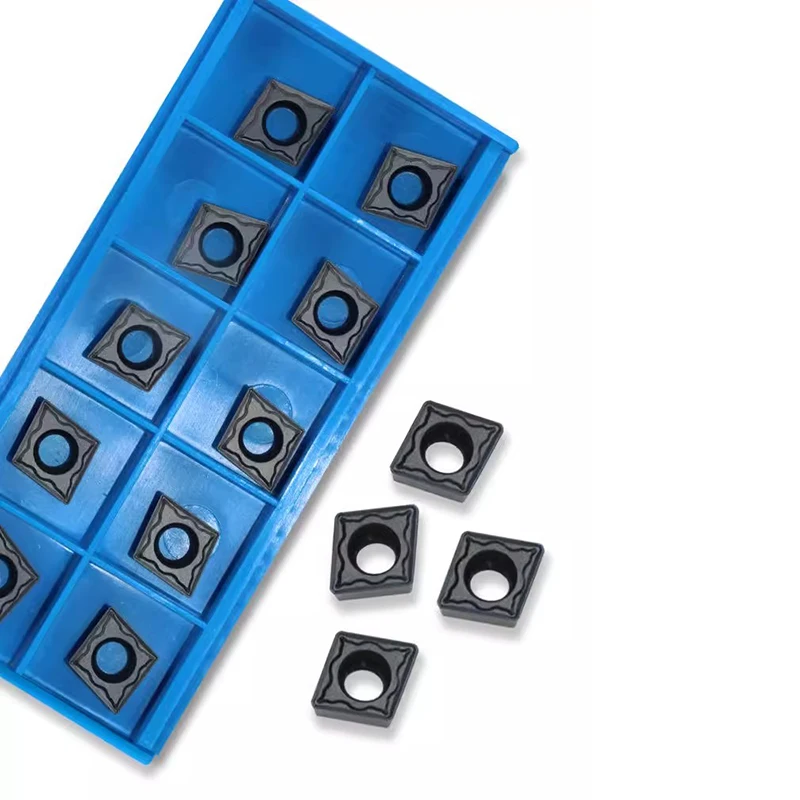

Packing & Delivery

To better ensure the safety for your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

* Contact the seller for discounts on bulk purchases

Company Profile

Guangdong Tianyu Machinery Equipment Co., Ltd provides superior products and services through understanding the needs of our customers. Our Tool Engineering Centersstrongly support manufacturing byoffering a variety of services tailored tothe customer's needs.

FAQ

1) When can I get the price?

We usually quote within 12 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in

your email so that we will regard your inquiry priority.

2) How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you just need a blank sample to check the design

and paper quality, we will provide you sample for free, as long as you afford the express freight.

3) How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3 days. The samples will be

sent to you via express and arrive in 3-5 workdays. You can use your own express account or prepay us if you do not have an

account.

4) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 15-30 days. We need 7-15 days to prepare all the stuff then 15 days

for manufacturing.

5) What about the transportation and delivery date?

Normally we use shipment to transprot the goods.It is about 25-40 days.It also denpends on which coutry and port you are.It could

be shorter if you need to send the goods like Asian. If there are some emergencies we can send the goods via air express, as long

as you afford the traffic expense.

6) Are you trading company or manufaturer?

We are a professional integrated business of industry and trade. We not only owns our tool factory, but also have cemented carbide

factory and a complete supply chain system.We have rich experience in production experience, high-volume production orders.

7) Where is your factory located?

We are located in No. 20 Jiangnan West Street, Chang'an Town, Dongguan City, Guangdong Province.

8) How about your stock?

We have a large inventory of products, with regular models and sizes in stock. All items that can be paid directly are in stock.

If you are unsure, please contact us.

9) Is free shipping possible?

We do not offer free delivery services. If you purchase a large quantity of products, we can pay for the shipping cost.

We usually quote within 12 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in

your email so that we will regard your inquiry priority.

2) How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you just need a blank sample to check the design

and paper quality, we will provide you sample for free, as long as you afford the express freight.

3) How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3 days. The samples will be

sent to you via express and arrive in 3-5 workdays. You can use your own express account or prepay us if you do not have an

account.

4) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 15-30 days. We need 7-15 days to prepare all the stuff then 15 days

for manufacturing.

5) What about the transportation and delivery date?

Normally we use shipment to transprot the goods.It is about 25-40 days.It also denpends on which coutry and port you are.It could

be shorter if you need to send the goods like Asian. If there are some emergencies we can send the goods via air express, as long

as you afford the traffic expense.

6) Are you trading company or manufaturer?

We are a professional integrated business of industry and trade. We not only owns our tool factory, but also have cemented carbide

factory and a complete supply chain system.We have rich experience in production experience, high-volume production orders.

7) Where is your factory located?

We are located in No. 20 Jiangnan West Street, Chang'an Town, Dongguan City, Guangdong Province.

8) How about your stock?

We have a large inventory of products, with regular models and sizes in stock. All items that can be paid directly are in stock.

If you are unsure, please contact us.

9) Is free shipping possible?

We do not offer free delivery services. If you purchase a large quantity of products, we can pay for the shipping cost.

Has multiple processing capabilities

We have various machining capabilities, please feel free to inquire

We Recommend

New Arrivals

New products from manufacturers at wholesale prices