Fullcryo 99.6% 99.8% high purity oxygen plant gas generation equipment for steel industry

- Category: >>>

- Supplier: Beijing Sinoscience Fullcryo Technology Co. Ltd.

Share on (1601168318714):

Product Overview

Description

Products Description

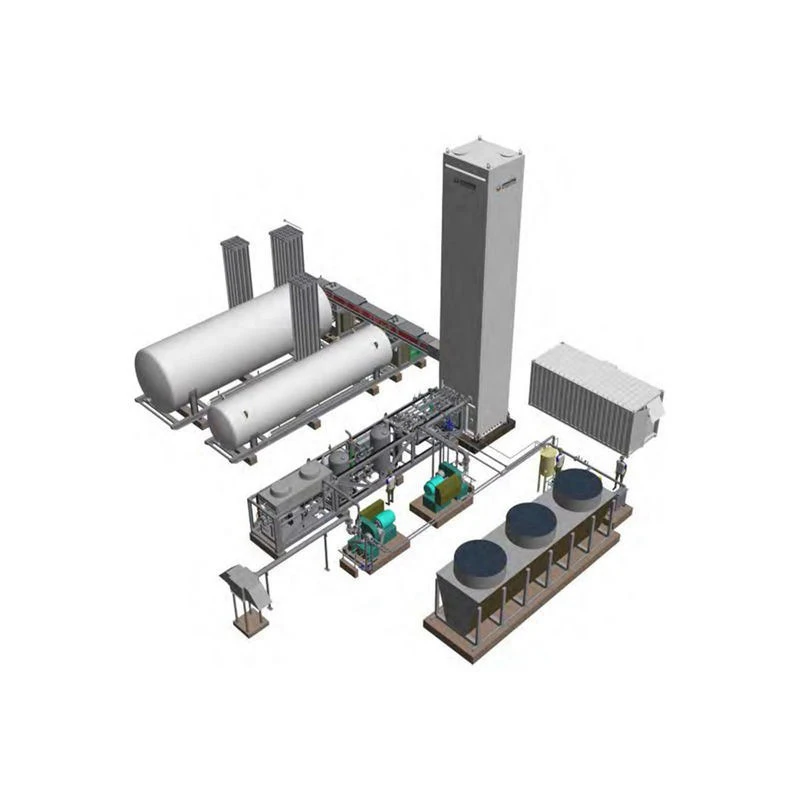

What is ASU?

Cryogenic air separation unit is a device for separating oxygen, nitrogen, argon or other gases from the air. The principle is try to cool the air into liquid at first, then take advantage of the different boiling points of oxygen, nitrogen and argon components(-183℃, -196℃, -186℃),thus having different sequence of evaporation to separate them.With rectifying of upper column, nitrogen will be obtained liquid oxygen at bottom of upper column.Draw some argon fraction from upper column and send to crude argon column,after rectifying of crude argon column then enters pure argon column for further rectifying will obtain pure argon with nitrogen content less than 3ppm.

Technological process flow:

1 、Impurity purification system: mainly through the air filter and molecular sieve absorber device, purification air mixed with mechanical impurities, water, carbon dioxide, acetylene and so on.

2 、Air cooling and liquefaction system: mainly composed of air compressor, heat exchanger, expander and air throttle valve, play the role of deep freezing air.

3 、Air rectification system: the main components are rectifying column (upper tower, lower tower), condensing evaporator,subcooler, liquid air and liquid nitrogen throttle valve.

4 、Heating and blowing system: The purification system is regenerated by heating and blowing.

5 、Instrument control system: control the whole process through various instruments.

Technological process flow:

1 、Impurity purification system: mainly through the air filter and molecular sieve absorber device, purification air mixed with mechanical impurities, water, carbon dioxide, acetylene and so on.

2 、Air cooling and liquefaction system: mainly composed of air compressor, heat exchanger, expander and air throttle valve, play the role of deep freezing air.

3 、Air rectification system: the main components are rectifying column (upper tower, lower tower), condensing evaporator,subcooler, liquid air and liquid nitrogen throttle valve.

4 、Heating and blowing system: The purification system is regenerated by heating and blowing.

5 、Instrument control system: control the whole process through various instruments.

Product Paramenters

Product Name | Cryogenic Air Separation Unit |

Purity | O2 :>99.6% ,N2 :≤ 3PPm O2, Argon: ≤2PPm O2+3PPm N2 |

Productivity | 50Nm3/h~80000Nm3/h |

Output | Oxygen Gas /Liquid Oxygen/Nitrogen Gas /Liquid Nitrogen/Argon or customized |

Operation Cycle | 24 Months |

Oxygen Application | Metal cutting and welding;Medical treatment;Mining and mineral processing;Aerospace industry;Metallurgy;Laboratory;Iron and steel industry;Chemical industry,etc. |

Nitrogen Application | Metal smelting and processing industry;Chemical;Petrochemical;Tire rubber, Electronics industry;Food storage; Laser cutting;Biology;Medical treatment,etc. |

Argon Application | Used as shielding gas in welding、argon arc welding;Metal melting industry;Refining of semiconductor materials and rare metals,Make arc lamps,Electrons industry,etc |

Company Profile

Beijing Sinoscience Fullcryo Technology Co.,Ltd. was established in 2016 in Beijing, with a registered capital of 45 million USD and a plant area of more than 33000m2 in Guangdong province. Fullcryo is a state-owned enterprise and licenser controlled by the Technical Institute of Physics and Chemistry,Chinese Academy

of Science.

Fullcryo specializes in the R&D and manufacturing of large-scale cryogenic equipment with working temperature below 20K to satisfy the requirements of various large-scale scientific facilities. At present, Fullcryo has 23 holding subsidiaries, including headquarters, engineering and manufacturing facilities, gas sales and project management companies. Our aim is to become a global leading manufacturer of cryogenic equipment and a pioneer of gas processing technological solutions.

of Science.

Fullcryo specializes in the R&D and manufacturing of large-scale cryogenic equipment with working temperature below 20K to satisfy the requirements of various large-scale scientific facilities. At present, Fullcryo has 23 holding subsidiaries, including headquarters, engineering and manufacturing facilities, gas sales and project management companies. Our aim is to become a global leading manufacturer of cryogenic equipment and a pioneer of gas processing technological solutions.

With its core competence of scientific achievement in super-cryogenics, from -100℃ down to -269℃, Fullcryo has become a leading company in turnkey engineering and professional manufacturing business. Our main technical applications and business scope include:Helium Extraction From Natural Gas & LNG,Helium & Hydrogen Liquefier,Helium Refrigerator,Cryogenic Air Separation Unit(Oxygen/Nitrogen/Argon),Rare Gas Extraction & Rectification Unit (Krypton-Xenon),Vacuum Nitrogen Generator,PSA/VPSA Generator,as well as Cryogenic Storage and Transportation with ISO, CE and ASME certification.Fullcryo is the world's third corporation with full intellectual property right on large-scale super-cryogenic engineering .

Fullcryo are committed to delivering high-level product services to world class standards.

Certifications

Our Advantages

Design Capability

◇Strong R & D capability of air separation process

◇Full simulation 3D modeling capability

◇Full simulation 3D modeling capability

◇Automatic variable load ALC and advanced control APC design capability

◇ Large air separation process design, rare gas refining device engineering design capabilities

◇ Large air separation process design, rare gas refining device engineering design capabilities

Engineering capability

◇Core cryogenic equipment manufacturing capabilities

◇Complete sets of equipment capabilities for multiple types of air separation units

◇Complete sets of equipment capabilities for multiple types of air separation units

◇Provide air separation unit turnkey project service

Operational capability

◇Professional air separation operation and management team

◇24-hour real-time monitoring by remote control center

◇A nationwide air separation sales network

◇24-hour real-time monitoring by remote control center

◇A nationwide air separation sales network

◇Save operating costs and improve economic and social benefits for users

Exhibition

FAQ

Q1. What is your main product ?

A1: Oxygen gas plant , nitrogen gas plant , liquid oxygen plant , liquid nitrogen plant , liquid argon and rare gas plant ...

Q2. What is your terms of payment?

A2: T/T 30% as deposit, 30% in the middle of manufacturing period,and balance before delivery./To be negotiated.

Q3. What is your terms of delivery?

A3: EXW, FOB, CFR, CIF, etc.

Q4: How to get a prompt quotation?

A1: Oxygen gas plant , nitrogen gas plant , liquid oxygen plant , liquid nitrogen plant , liquid argon and rare gas plant ...

Q2. What is your terms of payment?

A2: T/T 30% as deposit, 30% in the middle of manufacturing period,and balance before delivery./To be negotiated.

Q3. What is your terms of delivery?

A3: EXW, FOB, CFR, CIF, etc.

Q4: How to get a prompt quotation?

A4:When you send us inquiry, please kindly tell us the below technical information.

1) O2/N2/Ar Production capacity: ____Nm3/h

2) O2/N2/Ar Purity: ____%

3) O2/N2/Ar Discharge pressure: ____Bar

4) Local Voltages and Frequency: _____V/PH/HZ

5) Application or use for which industry:_____(industrial use or medical use,etc)

6) Altitude and atmospheric conditions:_____m

1) O2/N2/Ar Production capacity: ____Nm3/h

2) O2/N2/Ar Purity: ____%

3) O2/N2/Ar Discharge pressure: ____Bar

4) Local Voltages and Frequency: _____V/PH/HZ

5) Application or use for which industry:_____(industrial use or medical use,etc)

6) Altitude and atmospheric conditions:_____m

Q5: Can you make the equipment according to buyer’s request?

A5: Yes, OEM accepted.

Q6: How do you pack the product before delivery?

A6: We packed wooden cases which in accordance with the export standards.

Q7: Can you please specifically describe your warranty terms?

A7: The period of warranty is 12 months since the completion day of installation and commissioning.

A5: Yes, OEM accepted.

Q6: How do you pack the product before delivery?

A6: We packed wooden cases which in accordance with the export standards.

Q7: Can you please specifically describe your warranty terms?

A7: The period of warranty is 12 months since the completion day of installation and commissioning.

We Recommend

Cryogenic air Separation Unit Gas with Two Columns Oxygen Nitrogen Producing Manufacturers

$170,000.00-180,000.00

New Arrivals

New products from manufacturers at wholesale prices