Manufacturer Direct Press Brake Die for Sheet Metal Bending Hydraulic Tools

- Category: >>>

- Supplier: Accurl Cnc Machine(anhui) Manufactory Co. Ltd.

Share on (1601168422876):

Product Overview

Description

Products Description

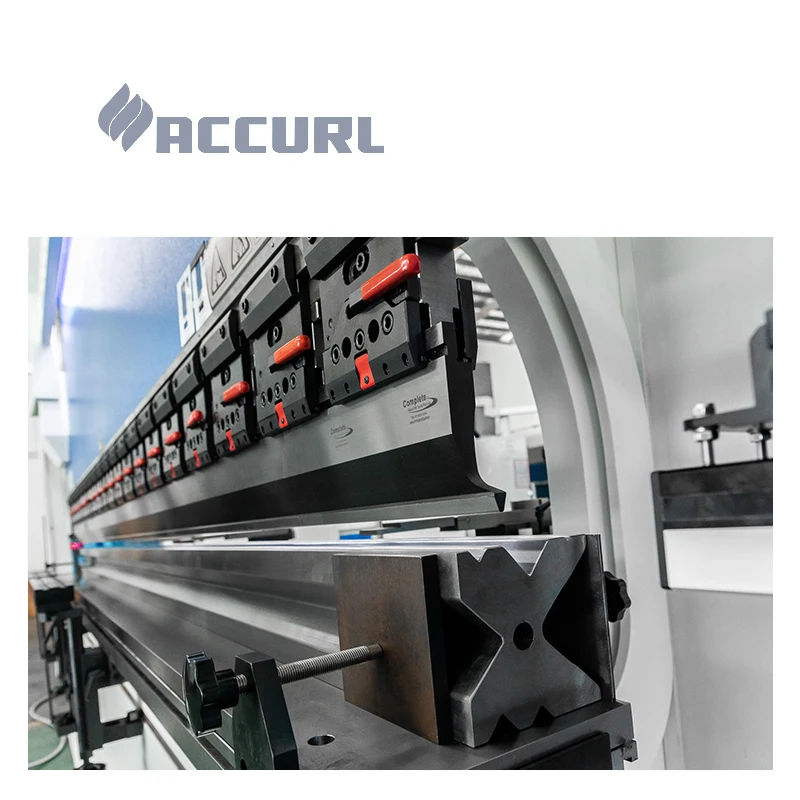

ACCURL PRESS BRAKE TOOLING

ACCURL® tooling is mainly suitable for the material selection of bending machine, such as thin, medium, thick plate, cold and hot transverse shear, longitudinal cutting, rolling, hot rolling, etc.: t8a, t10a, 55sicr, and 42crmo quenching hardness (hrc): the product features of the following 55 °: the concentricity is good, the precision is high, the whole quenching is high, the surface finish is high, the wear resistance and the tolerance are high: Up to 0.02, up to the import ammada standard product price: according to the different mould requirements, and the size and the mould type, the precision bending machine mould upper die is:90 °,88°,26°,35 °,45 °,60 ° and 30 ° lower mould:88 °,90 °,35 °,60 °,30 °,45 °; CNC bending tool segment, general segment specification is as follows: mold segment 1 numerical control bending upper mold:100 (left),10,15,20,40,50,200,300,100 (right) = 835 mm

numerical control bending lower mold:10,15,20,40,50,100,200,400 = 835 mm mold segment 2

numerical control bending upper mold:100(left),10,15,20,40,50,165,300,100 (right) = 800 mm

Details Images

LOWER TOOLS H65/60° DIES

LOWER TOOLS H55/80° DIES

LOWER TOOLS CORNER ROLL DIES

DIE FEATURES:

1.Most tools can be easily loaded by a single operator. 2. Easy to store.

3. All sectionalised tools come pre-cut in nine different pieces.

4. Most sectionalised punches include two ear pieces (horns).

5. Punches are induction hardened, to 59-60 HRC but NITREX™ (HRC-60) is available for every punch in the tooling line.

1.Most tools can be easily loaded by a single operator. 2. Easy to store.

3. All sectionalised tools come pre-cut in nine different pieces.

4. Most sectionalised punches include two ear pieces (horns).

5. Punches are induction hardened, to 59-60 HRC but NITREX™ (HRC-60) is available for every punch in the tooling line.

ACCURL HEAVY DUTY TOOLING

The design of the tool pays special attention to durability and precision control. v-opening adjustment range and tool length can be customized according to customer needs.

• Motorized v-opening adjustment, precise positioning every 10 mm

• Fast v-opening adjustment straight from cnc-control

• Strong and durable construction

• Excellent load resistance

• V-opening conner rolls to reduce the power needed in bending and improve tools duration

• Suitable for almost press brakes

• Almost maintenance free

• Motorized v-opening adjustment, precise positioning every 10 mm

• Fast v-opening adjustment straight from cnc-control

• Strong and durable construction

• Excellent load resistance

• V-opening conner rolls to reduce the power needed in bending and improve tools duration

• Suitable for almost press brakes

• Almost maintenance free

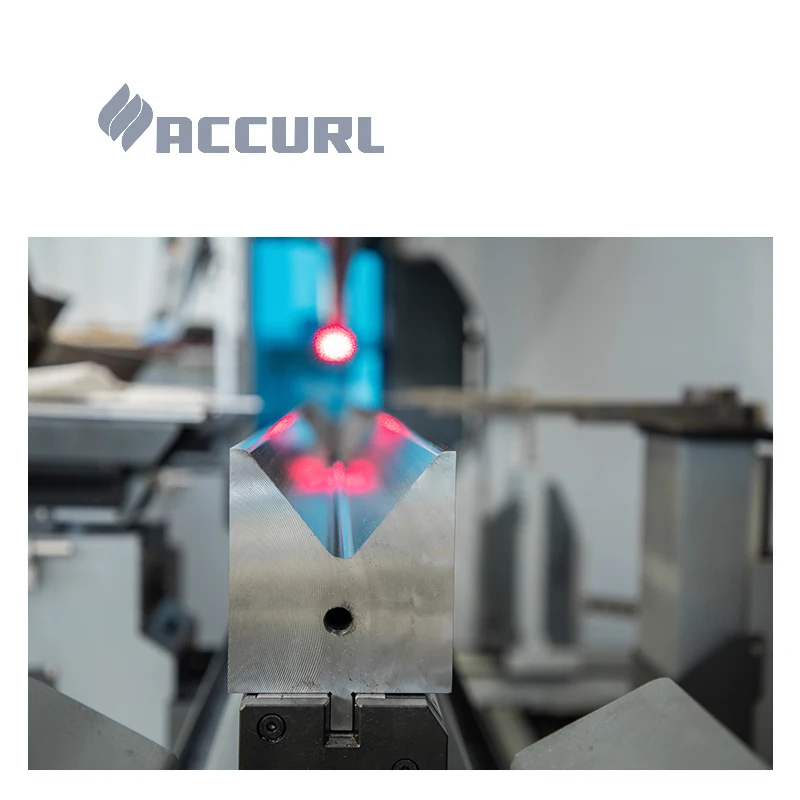

ACCURL CNC-VARIO DIE

FAST V-OPENINGS ADJUSTMENT

STRAIGHT FROM CNC-CONTROL

STRAIGHT FROM CNC-CONTROL

The design of the tool pays special attention to durability and precision control. v-opening adjustment range and tool length can be customized according to customer needs.

• Motorized v-opening adjustment, precise positioning every 10 mm

• Fast v-opening adjustment straight from cnc-control

• Strong and durable construction

• Excellent load resistance

• V-opening conner rolls to reduce the power needed in

bending and improve tools duration

• Suitable for almost press brakes

• Almost maintenance free

• Motorized v-opening adjustment, precise positioning every 10 mm

• Fast v-opening adjustment straight from cnc-control

• Strong and durable construction

• Excellent load resistance

• V-opening conner rolls to reduce the power needed in

bending and improve tools duration

• Suitable for almost press brakes

• Almost maintenance free

T y p e | Kg / m | H e i g h t / m m | α | M a x l o a d 9 0 ° t n / m | |||||

H65/60° DIES | V6-----V60 | 13,3--30,9 | 65 | 60 | 50--150 | ||||

H100/60° DIES | V12--V100 | 21,0--100,5 | 100--120 | 60 | 125--270 | ||||

H100/30° DIES | V12--V40 | 24,4--37,7 | 100 | 30 | 80--130 | ||||

H55/80° DIES | V8--V50 | 9,8--28,4 | 55 | 80 | 50--125 | ||||

H100/80° DIES | V40---V100 | 45,1--72,9 | 100 | 80 | 200--250 | ||||

>H120/80° DIES | V120---V300 | 109,7--427,9 | 120---230 | 80 | 250 | ||||

(Other than above standard length, we manufacture any length upon customer's request.Max:6100mm) | |||||||||

WHY TO CHOOSE ACCURL TOOLING ?

• High-class materials

• Top quality production

• Right solutions for customer’s needs

• Wide range of tooling solutions

• Max load up to 600 t/m

• Quick and easy tools change

• Improving of equipment productivity

• Guarantee

• Improves productivity of the press brake

• Improves bending quality

• Helps production planning

• Improves occupational safety

Related Products

Company Profile

Why choose us?

ACCURL is a famous manufacturer of metal sheet equipments in world market. Its Brand ¡°Accurl¡± has been leading brand for many years in the field of international metal sheet equipments. Our group devote ourselves to product development, production and sales.

Our main products are: CNC Press Brake, Shears, Hydraulic press, Laser Cutter and CNC rolling machine these sheet metal processing equipments.we are using advanced technology from German, Japan, and Italy.we can produce large Hydraulic Press and Press Brake more than 16000 ton & 16m.we are with professional R&D team, and we have World-class design and manufacturing capabilities.

Technological Process

We Got 5 Stars Rating!

Exhibition

Production Power

The Robot Arm

OEM Press Brake

OEM Press Brake

Our American dealers came to visit the factory

Product packaging

1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2.All the spare parts of themachine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

Our serives

QUALITY CONTROL

Nearly 50 years of expertise in the manufacture of press brakes and guillotines machines give us the security that is needed for future challenges. High standards of quality and a team with the best training and knowledgeare a major condition for our success.

Our products are the result of a continued focus on improving internal processes underpinned by high quality levels, that result in the recognition ofAccurl' s machines as quality garantee equipment.

Our products are the result of a continued focus on improving internal processes underpinned by high quality levels, that result in the recognition ofAccurl' s machines as quality garantee equipment.

FAQ

1.Can you supply the relevant documentation?Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices