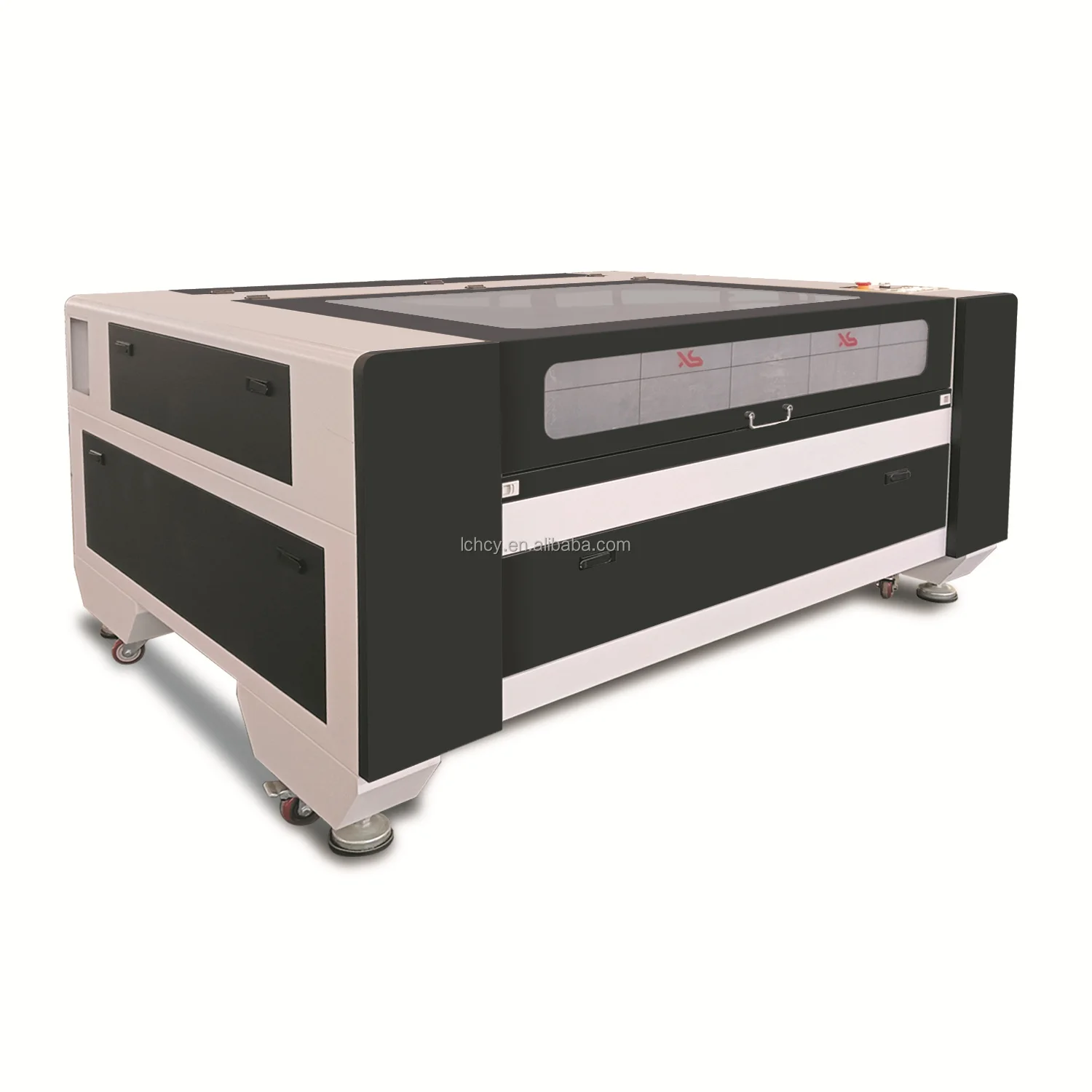

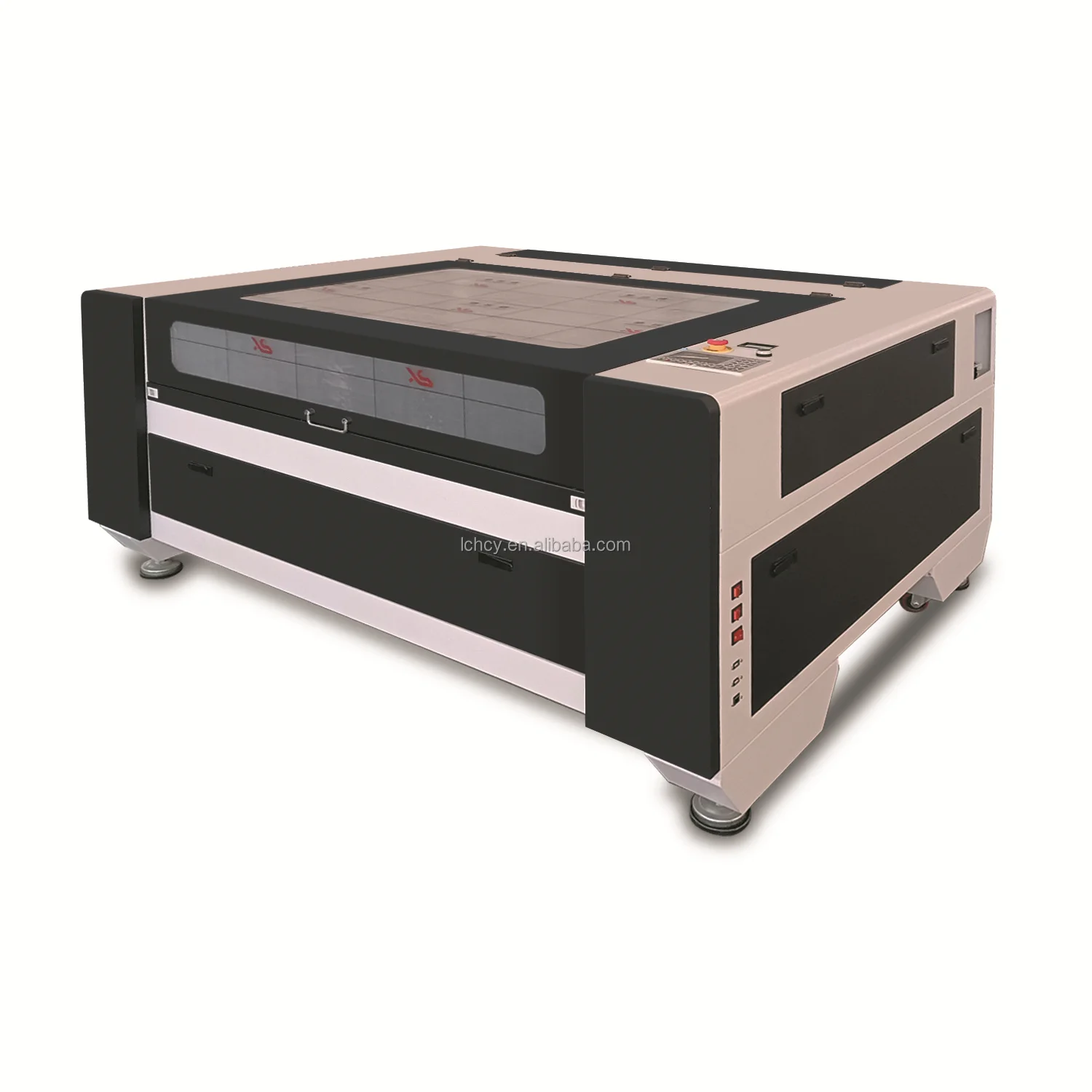

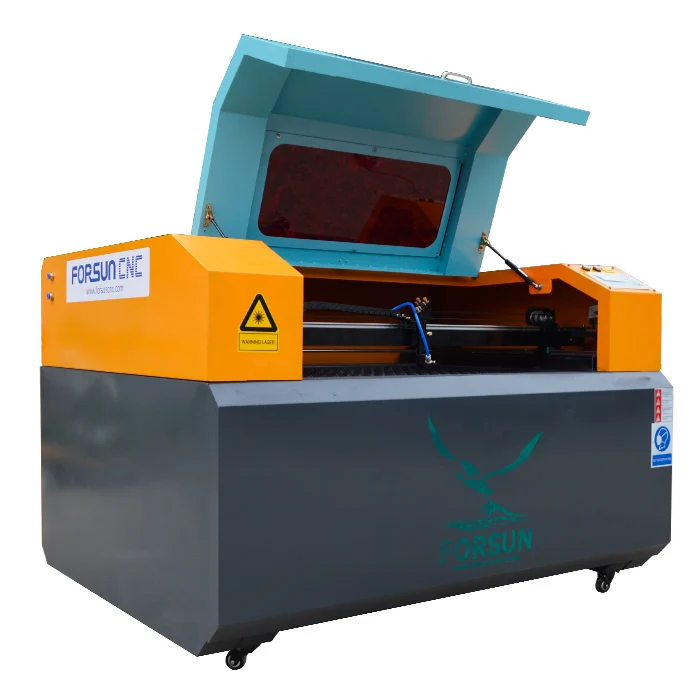

150watt 180W CO2 laser/1390 Laser Cutting Machine/Laser Cutter and Engraver for Sale

- Category: >>>

- Supplier: Liaocheng Hengchunyuan Machinery Equipment Co. Ltd.Liaocheng Ltd.

Share on (1601169050477):

Product Overview

Description

Introduction

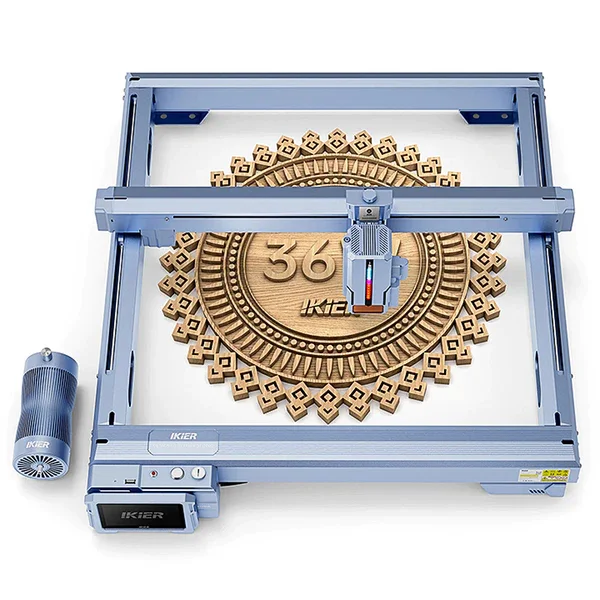

This machine is our RUIDA CONTROL CO2 LASER ENGRAVING CUTTING MACHINE FL-1390.

It is equipped with a precise water cooled co2 laser tube (Reci, YONGLI, EFR, SLW, XINRUI..) that can engrave almost any nonmetal materials on almost any surface. The machine can also be used for cutting many different materials.

It supports multiple graphic formats, such as PLT / DXF / BMP / JPG / GIF / PGN / TIF and so on. This machine is equipped with DSP Control System for CorelDraw/AutoCAD and other advanced software. It is compatible with WIN10, WIN8, WIN7, Vista and XP.

Specifications of co2 laser cutting machine 1390

| Machine type | co2 laser cutting machine 1390 |

| Laser power | 80W, 100W, 130W, 150W, 180W, 300W, 500W |

| Power supply | 110V/220V, 50Hz/60Hz |

| Working area | 1300x900mm |

| Max moving speed | 1000mm/s |

| Locating precision | <0.01mm |

| Min shaping character | Letter: 1x1mm |

| Max cutting speed | 500mm/s |

| Resolution ratio | ≤4500dpi |

| Control configuration | DSP |

| Data transfer interface | USB(offline) |

| System environment | WINDOWS XP/ VISTA / WIN 7 / 8 / 10 |

| Cooling way | Water Cooling with Chiller CW3000 or CW5000 |

| Graphic Format Supported | The Files which CorelDraw, Photoshop, AutoCAD can identify (BMP, JPEG, PCX, TIFF, PLT, CDR, DXF, etc) |

| Compatible software | CorelDraw, AutoCAD, Photoshop |

| Cutting thickness | 0-20mm (depends on different materials) |

| Color separation | Separation of cutting up to 256 colors |

| Sloping engraving | Yes, slope can be designed discretionarily |

| Cuts off the water supply the protection | Yes |

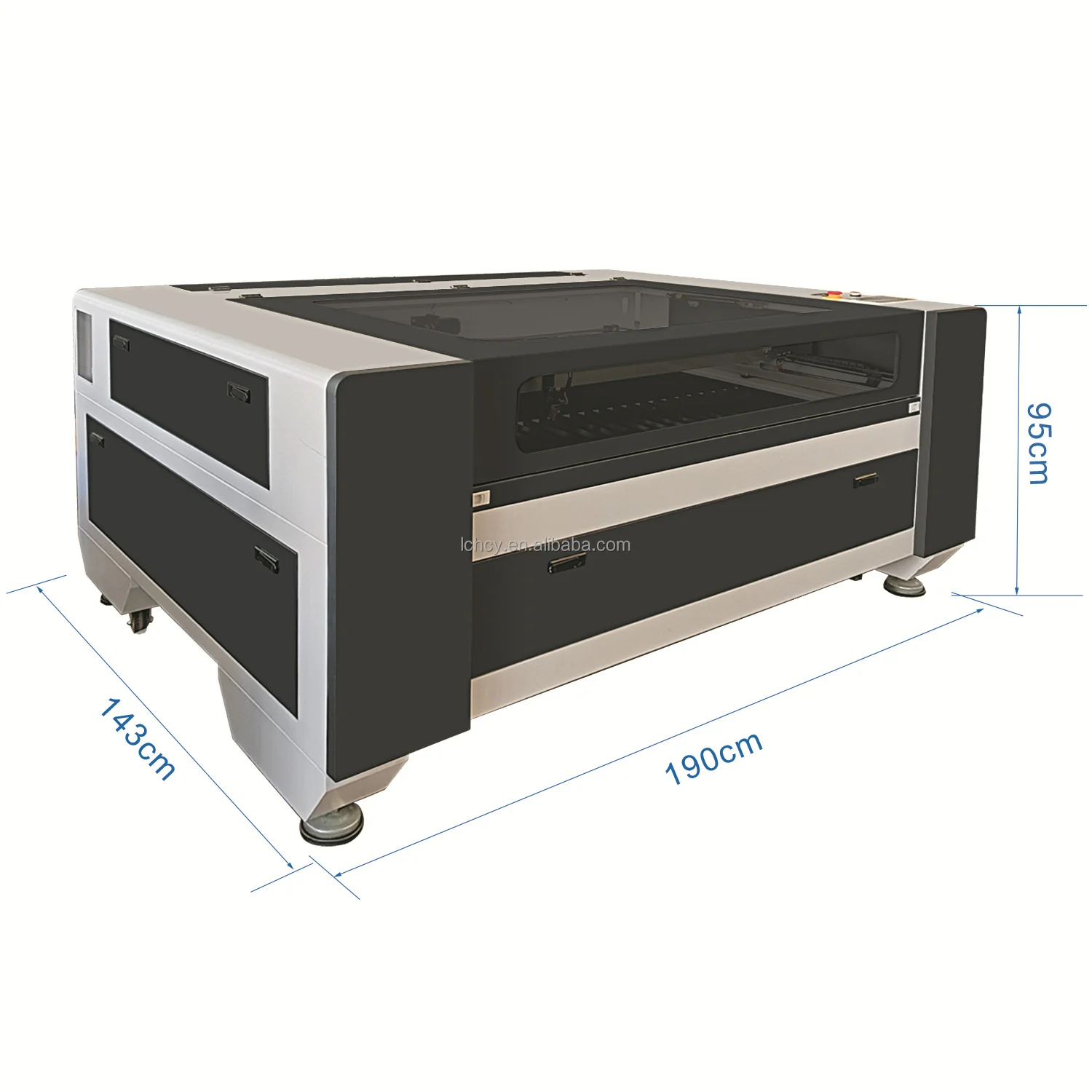

| Machine Dimension | 1900*1455*1040mm |

| Pacakge dimension(wood package) | 2000*1560*1210mm |

| Machine weight | 450 kgs |

| Package weight | 500 kgs |

- High flexibility due to various additional options

- Smooth cutting edges, no glitches, no burns, no need to rework

- No fixing of material necessary due to contactless and forceless processing

- Freely selectable contours especially for printed materials due to optical recognition system

- Laser engraving and laser cutting in one single process step

- Open software structure (file formats e.g. dxf, ai, pdf)

- Ball screw transmission on Z axis

- Imported electronic components

- Wifi control --- one computer can control multiple laser sets

Please check the photos below of co2 laser cutting machine 1390 in detail:

High precision laser head

Standard aluminum blades worktable for laser wood cutting machine price

Ruida RDworks V8 control

Tidy wiring inside 100w laser cutting machine 1390

Best glass Co2 laser tube with good tube amount

Optional Auto Focus for Easy Focus

Optional CCD Visual Camera for Contour Cutting

Optional Dual Heads/4 Heads for More Efficient Production

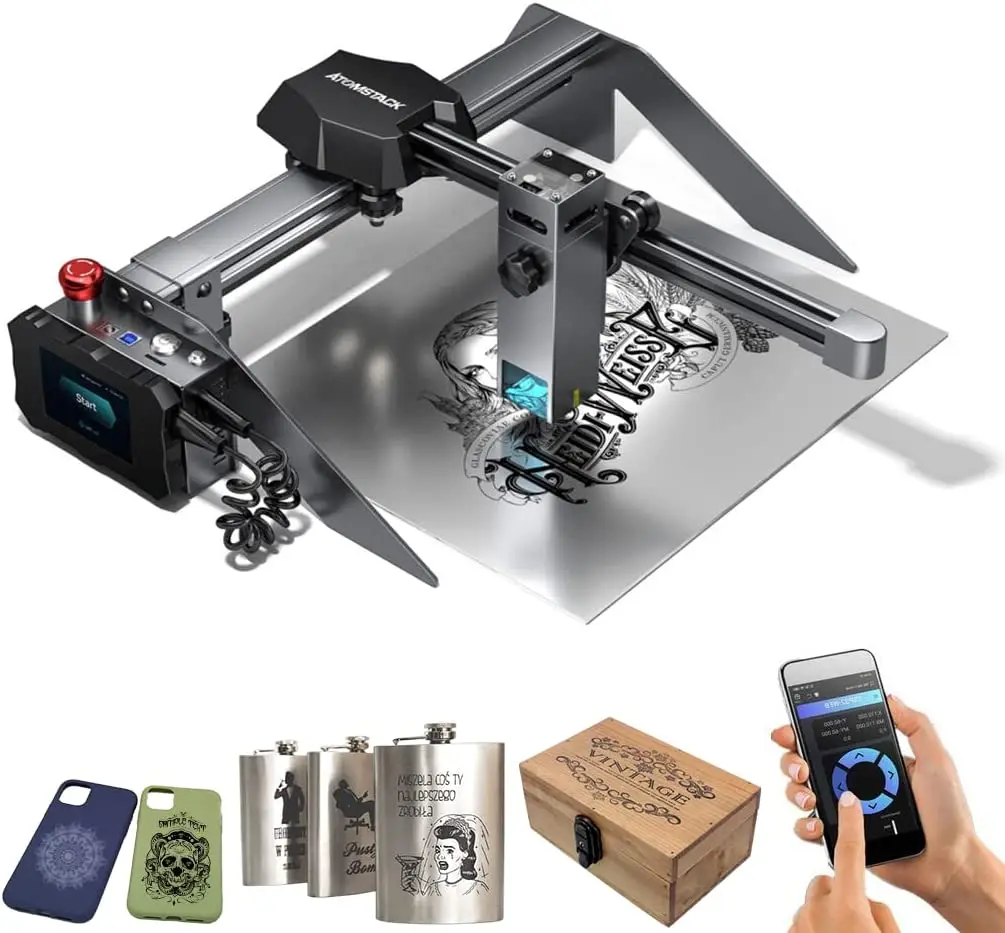

Laser Applications of co2 laser cutting machine 1390

co2 laser cutting machine 1390 can be used to process almost all the nonmetal and coated-metal materials, wood, acrylic, rubber, granite, glass, etc.

- Aerospace

- Architectural Modelmakers

- Automotive

- Aviation

- Awards and Trophies

- Branding and Logo Personalisation

- Electrical Component & Assembly Contractors

- Games Pieces, Boards, etc.

- Granite and Stone Engraving

- Image Engraving

- Coated Metal Engraving

- Photo & Image Engraving

- Plastic Fabrication

- Sign Makers

- Specialist Packing & Packaging

- Textiles and Fabrics

- Woodwork and Veneers and more!

It shows great performance on cutting WOOD and ACRYLIC for DIFFERENT WORKPIECES, such as ARCHITECTURE MODEL, AIRPLANE MODEL, NAMECARDS, SIGNBOARDS, etc.

If you are not sure if the machine can engrave or cut your workpieces, just contact me freely!

Send Me Inquiry Here!

WhatsAPP/WeChat: +8618763593952

1. Outside package: Standard marine export plywood case.

2. Inner package: Stretchy film and plastic film for humidity.

We can package according to your requests.

We work with dozens of international freight companies to build long-term relationships that reach all countries and regions around the world, and their experience in shipping will keep your machines safe. We can also provide train transportation,especially in Russia, Ukraine and other landlocked countries.

The whole package of co2 laser cutting machine 1390 by wood case includes:

1 * Water Chiller

1 * Smoke Pipe

1 * Main Body

1 * Air Pump

1 * Power Line

1 * Wrench

1 * Exhaust Fan

1 * Laser Tube

1 * CD

1 * Manual

1 * USB Cable

1 * Manual/Accessory Bag

1 * Cylinder Rotary Attachment(optional)

We try our best to making your experience with us a positive one and therefore we stand behind everything we sell.

2. 24 hours technical support by e-mails, calls and door-to-door service overseas.

3. English software, user manual and CD.

4. Machine spare parts' repair service is also availble.

Whether you are cutting acrylic, plastic or advertising signs, whether you are in the field of architecture model or veneer marquetry, whether you are working with paper or cardboard… Laser cutting has never been so simple, accurate, and fast! As one of the China leading manufacturers of co2 laser cutting machine 1390, Flash Laser (our brand name) offers a full scope of state-of-the-art laser equipment to deliver quick, clean, quality results for a broad range of industrial laser cutting needs.

Q1. Is it easy to operate 100w co2 laser cutting machine 1390 for the new user ?

A: It is very easy ,we offer you operating video for English language ,also our technician can help you via MSN ,Skype teamviewer etc.

Q2. What i need to do when 100w co2 laser cutting machine 1390 suffers trouble?

A: Make sure all the wires be connection well ,and keep your lens and mirrors be clean ,then check your laser tube and talk details to us.

Q3. How to maintain the 100w co2 laser cutting machine 1390?

A: After 3 hours working, it’s better close 10 minutes. B, Keep lens and mirrors clean. C, The water for laser tube should keep clean and lower temperature, in winter you need input antifreeze.

Q4. How can I know the power of the laser tube has been exhausted?

A: you can check the color of the laser beam ,new and strong laser tube is purple when working, otherwise it will be white color.

Q5. Is it better to increase blow system to improve laser processing performance of 100w co2 laser cutting machine 1390?

A: It works for some kind materials,it can stop firing.

Q6: How long time does it take for a learning of 100w co2 laser cutting machine 1390 operation ?

A: If you are able to use some basic graphic design software, it will only take a few hours to master the operation, You just need to do some simple tests on different processing materials to learn how to adjust the speed and laser power.

Q7. Is it harmful to human body when 100w co2 laser cutting machine 1390 is in operation ?

A: It is not harmful, as long as the laser don't direct shoot the skin and eyes.

Q8. Do I need buy two laser machines to engrave or cut separately?

A: No,our machine can fulfill two purpose .

Q9. How to distinguish laser tubes with different powers and applications?

A: 1. Laser tube length(relatively speaking, the longer, the bigger/stronger)

2. Laser tube diameter(relatively speaking, the thicker,the stronger)

3.The machine with bigger laser tube can cut deeper&more quickly, also its light spot is bigger, so it is better to choose low-power for engrave, such as 40w, 50w, or 60w and strong power for cutting.

4. If you are not familiar with shipping procedure and customs clearance, we can arrange door to door delivery for you (DDU & DDP).

Let's create a better future together!

We Recommend

New Arrivals

New products from manufacturers at wholesale prices