Full Automatic pet food processing machines Cat Dog Machines Equipment dog food extruder

- Category: >>>

- Supplier: Jinan Himax Machinery Co. Ltd

Share on (1601173676156):

Product Overview

Description

Full Automatic pet food processing machines Cat Dog Machines Equipment dog food extruder

Hot sell dog food extruder machine is used for processing for pet food. Which is high and new technical program as to catch the developing market. fish feed machine mainly use maize, fish powder, meat powder and some food additive as main raw material, through mixing, extruding, roasting, flavoring to get the final puffed pruducts.

This line is fully automatic, high capacity and with different of shapes. It can produce such as cat food, dog food, fish food, bird food and so on.

1 Raw Materials: adopts corn flour, fish meal as raw materials

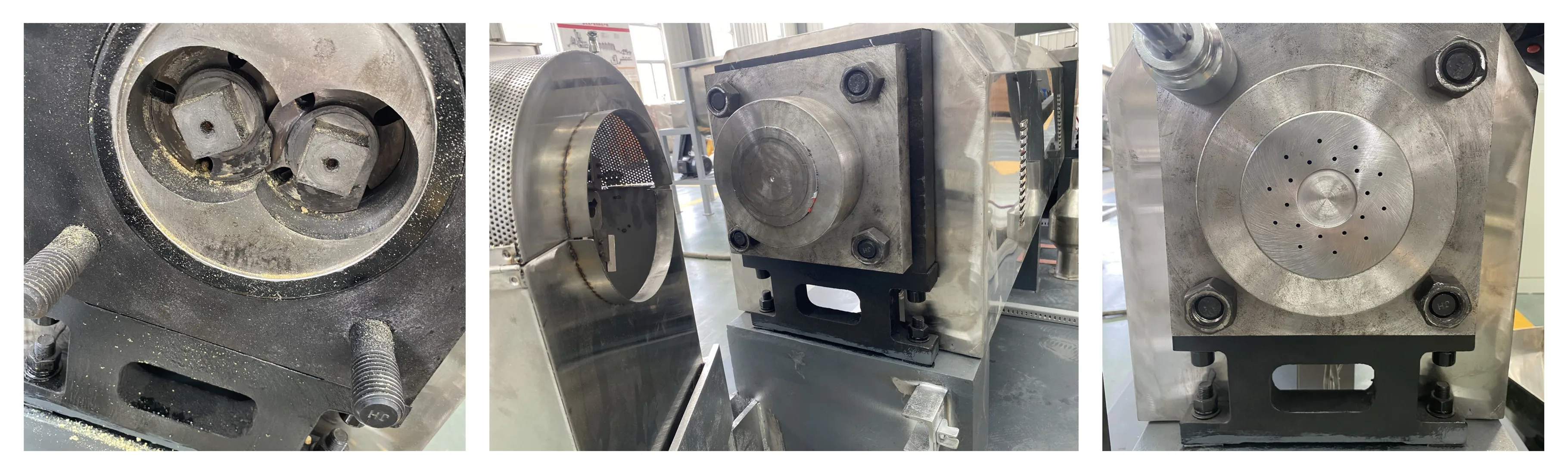

2 Products: different shapes are made by adjusting the dies from extruder

3 Capacity: 140 - 160kg/h, 240 - 260 kg/h, 500 - 600 kg/h, 1ton---3ton/h

4 Flow chart:

Mixing system---Extrusion system---Drying system---Flavoring system---Packing system

| Technical Items | Parameters |

| Motor power | 22kw |

| Heating power | 17kw |

| Feeding Moto | 0.75kw |

| Cutting Motor | 0.75kw |

| Power Installed | 30kw |

| Production capacity | 100-150kg/h |

| Weight | 1500kg |

| Dimension | 2600x900x1700mm |

5 Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

6 Machines Materials: All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

Details of Machine

Out of the oven into the skirt conveyor belt Material:PVC Prevent Cracking

Features of animal food machine

1. Gear directly-connecting driving is adopted for high efficiency;

2. Full stainless steel feeder; Variable pitch and anti bridging structure; Electromagneticconverter control;

3. Stainless steel conditioner; axial steam spraying extends the conditioning time and cooking effect;

4. Main gear and pinion shaft adopt the carbonizing quenching with high accuracy; smooth driving, low noise and long service life;

5. Gearbox and driving holes’ accuracy are guaranteed by specialized casting supplier and NCC.

Advantages:

1. Two shafts of conditioners

Two shafts of conditioners are different in diameter and rotational speed showing a different movement with opposite rotation direction,which makes the materials, steam and liquid be fully mixed,sheared and intersected by paddles of two shafts.

2.stainless steel conditioner

All parts in the conditioner are made of stainless steel.

3.Good Stability

The full-width opening structure of the conditioner facilities the operation and maintenance.The angle of the paddles can be adjusted freely.

Conditioners of HM fish feed extruder machine

The optimum conditioning of feed ensures you to get the highest performance out of a floating fish feed pellet machine. The gain of good conditioning:

* higher production throughput

* better pellet durability

* improved digestibility

* reduced pellet mill power consumption.

Kindly note:

All the Himax conditioners are made from stainless steel, have a very stable design and allow an easy installation on top of the pellet mill. We can customize different kinds of conditioners to meet your request.

Sample:

We always pay more attention to the quality of fish feed pellet machine. Standard quality control system and team are responsible to insure the product quality in every process with different instruments like fish feed extruder and fisn pellet machine. In the mechanical assemble process, the laser interferometer, laser callimator, dial indicator and marble plate are used; In the fish feed pellet extruder machine assemble process, the extruder powermeter and optical microscope are adopted.

We treat customers sincerely and pay more attention to how to maximize return of investment. We improve quality, reduce power consumption, shorten construction schedule, and quick feedback in terms of technology, production, engineering and service. We will furnish comprehensive, professional, and thorough service to meet customer's requirements. Thinking from customer's side, and solve problems timely.

- Technical support online service provided.

- Technical files service provided.

- On-site training service provided.

- Spare parts replacement and repair service provided.

We are a professional food machines manufacturer in Jinan City, China. We have much experience in Extrusion snack food processing, including Directly puffed snack food machine, Shaping and core filled snack food machine, Fried Crispy snack food machine, Popular Breakfast cereal Corn Flakes machine, Baby food machine, TVP/TSP machine, Modified Starch machine, Dog food machine and Fish food machine etc.

How to work about animal feed pellet machine, we will have a introduce for you as following:

1 The feed ingredients run through feeder into conditioner and will be conditioned & mixed in the conditioner with vapor, then it goes into the pelletizing chamber through blanking taper slot.

2 The powder material is feeded by scraper into the second pelletizing zone in the ring die. And then the material will be pressed by ring die and rollers into pellets.

3 The pellet is discharged from the die hole and cut into the requested size by the cutter.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices