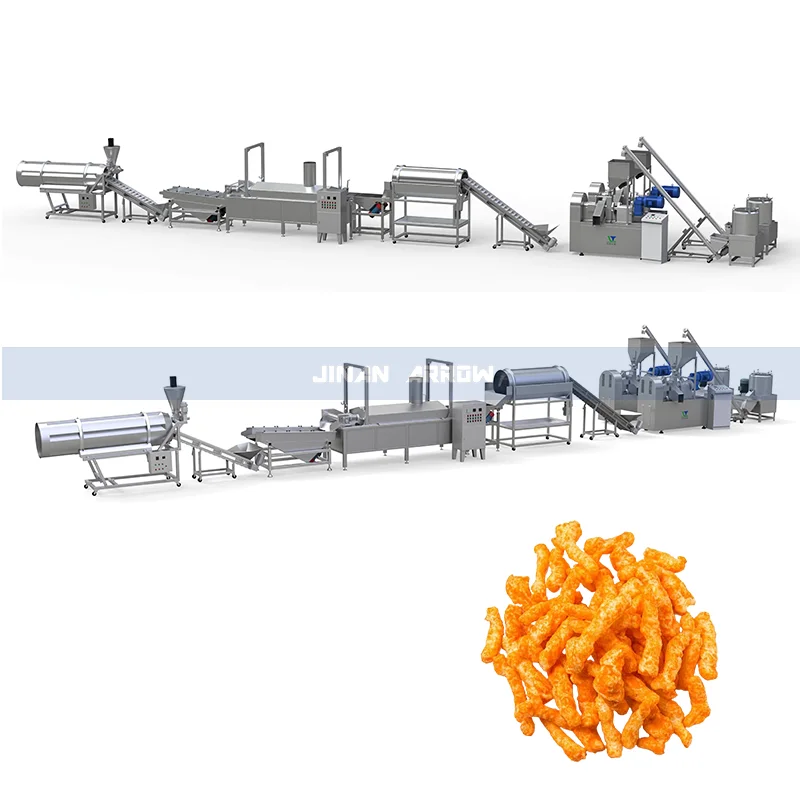

Hot Selling High Quality Food Grade Cheetos Snacks Food Making Machine

- Category: >>>

- Supplier: Jinan Arrow Machinery Co. Ltd.Jinan Ltd.

Share on (1601174848486):

Product Overview

Description

The Kurkure/Cheetos/Niknak/Corn Curls Process Line is a typical type extruded food machine studied and developed by us on the basis of learning from advanced technology in the world so that both its technical performance and products quality reach to the most advanced level in the world. This line can finish mixing, extruding, shaping, core-filling, cutting, baking and flavoring in one-pass operation automatically. This line features lots of types, flexible, collocation, extensive applied raw materials, various snacks and easy operation.

Kurkure/Cheetos/ Niknak are kind of special extruded snacks, very crunchy and delicious. They are made by a special extrusion process. The corn grits are moisturized by water in the flour mixer and fed to the rotary head extruder. In the extruder, due to the rubbing of two rotary plates, the corn grits are squeezed and twisted into curls shapes. The snack is then fried or baked to give it its crunchy texture and flavor. Once cooled, it is coated with a seasoning, such as cheese or spicy flavors, to give it its final flavor.

Baked Kurkure, Cheetos, Niknak Production Line

The production line can process baked flavored snacks, the taste of this type of leisure food is healthier, it is a good choice for investment.

Fried Kurkure, Cheetos, Niknak Production Line

Semi-automatic processing line for the production of traditionally popular fried flavors of Cheetos, kurkure, niknak, and other snack foods at a low cost of investment.

Feeding Part: Gravity feed hopper with vibrator for metered flow of raw materials. Speed control of the feed screw via the inverter(included).

Cutting System: Manual head gap is controlled by mechanical ratchet.

Customized Belt Types: We can customize the belts according to different products, like bugle or fish fillet which will easy to mark on the surface, we can use B-shaped or teflon made belt to avoid the marks and protect the crumbs surface.

Oil Level Indicator: It will give signal to the control panel, auto feed new oil when the level in the fryer is lower with the help of oil tank and pump.

Oil Level Indicator: It will give signal to the control panel, auto feed new oil when the level in the fryer is lower with the help of oil tank and pump.

The puffing snack process line uses corn, rice, wheat, oats, barley, etc. as raw materials, and can produce puffed snacks with stable quality and various shapes and textures. It can automatically complete the mixing, extrusion, forming, filling, cutting, baking, seasoning, and other processes at one time to produce puffed snacks with various formulas and flavors. The production line is easy to operate and maintain, capable of producing a large amount of puffed food in a short time.

Jinan Arrow Machinery Co., Ltd is a company specializing in R&D, production, sales, and application promotion of food engineering projects. As a professional food processing equipment &whole plant engineering solution solver in China, machines served more than 1200 companies, exported to 118 countries, and more than 30 years engineering team.

We aim to create a great future together with global customers. The quality of the equipment has been checked at various levels, and it has certificates such as CE, ISO9001, 18 practical patented technologies, and 6 software copyrights. Adhering to the concept of "Excellent quality, Prominent Service, Faithful Attitude, Promise Fulfilled "Our team from Pre-sale service and after-sale service will prove that your choice is worth it.

1. Are you a manufacturer or trader?

A: We are a professional manufacturer with more than 20 years of experience, with professional engineering and after-sales team.

2. What service do you supply?

A: We supply 7*24h service Pre-sale, in-sale and after-sale. ODM and OEM services are also available.

3. Do you supply relevant spare parts to buyers?

A: Yes, we will supply all spare parts of the machine to customers.

A: Yes, the motor voltage is customized, we will make it according to your requirements. Most commonly are 380V, 415V, 50/60HZ; 440V, 50/60HZ and 220V, 60HZ.

5. What other machines can you supply?

A: We are able to supply kinds of food machines, including breakfast cereal, corn flakes, tortilla chips, bugles, fried snacks, potato chips and etc. It will complete the solution from A to Z.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices