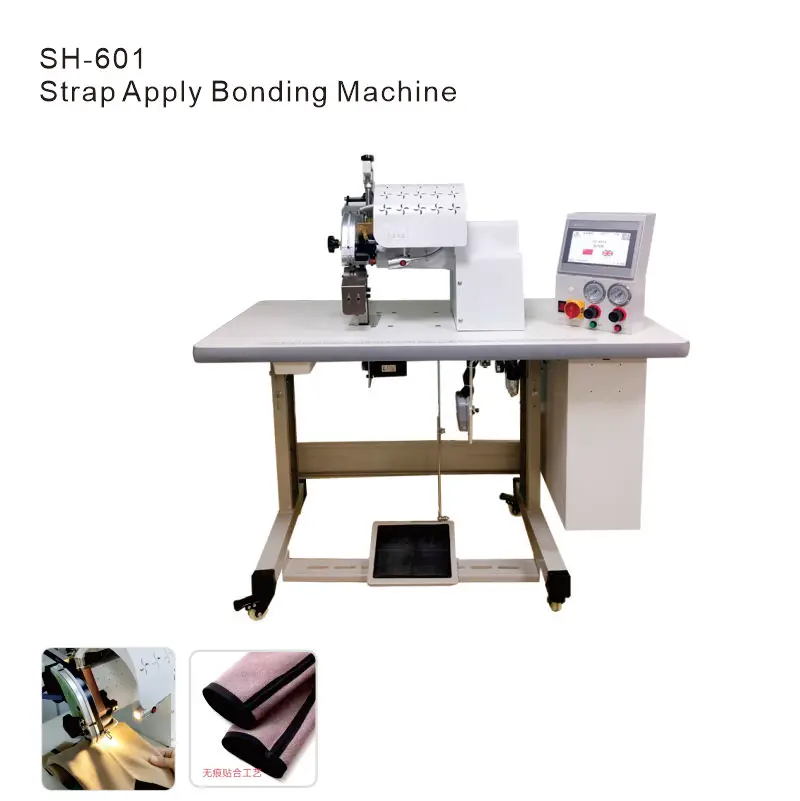

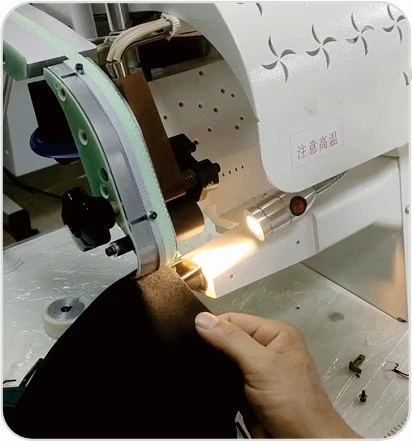

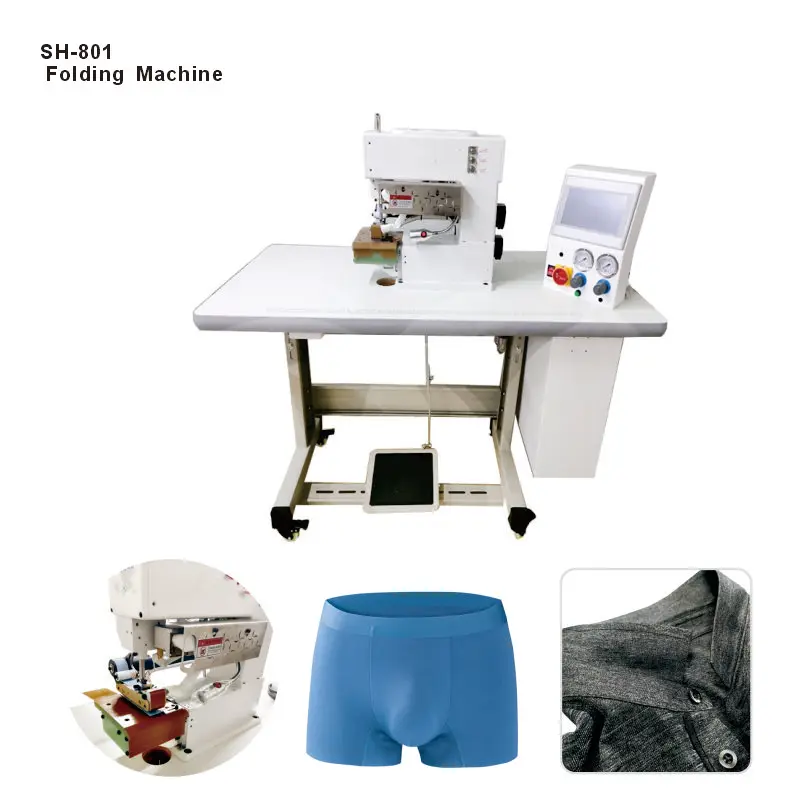

Seamless Technology and Bonding in Garment Production1. What is seamless technology in garment production?Seamless technology eliminates the need for traditional sewing by using bonding techniques to join fabrics. This method enhances comfort, durability, and the aesthetic appeal of garments by creating smooth, strong, and often invisible seams.

2. What are the main bonding techniques used in seamless garment production?The main bonding techniques include:

Thermal Bonding: Uses heat to activate adhesives and bond fabrics.

Cool Press Bonding: Applies pressure at lower temperatures, ideal for heat-sensitive materials.

Ultrasonic Bonding: Uses ultrasonic vibrations to cut and seal fabrics simultaneously.

3. What are the benefits of using seamless technology in garments?

Benefits include:

Enhanced Comfort: Smooth, seam-free interiors reduce chafing.

Improved Durability: Stronger bonds compared to traditional stitching.

Aesthetic Appeal: Cleaner lines and no visible stitching.

Faster Production: Automated bonding processes are quicker than sewing.