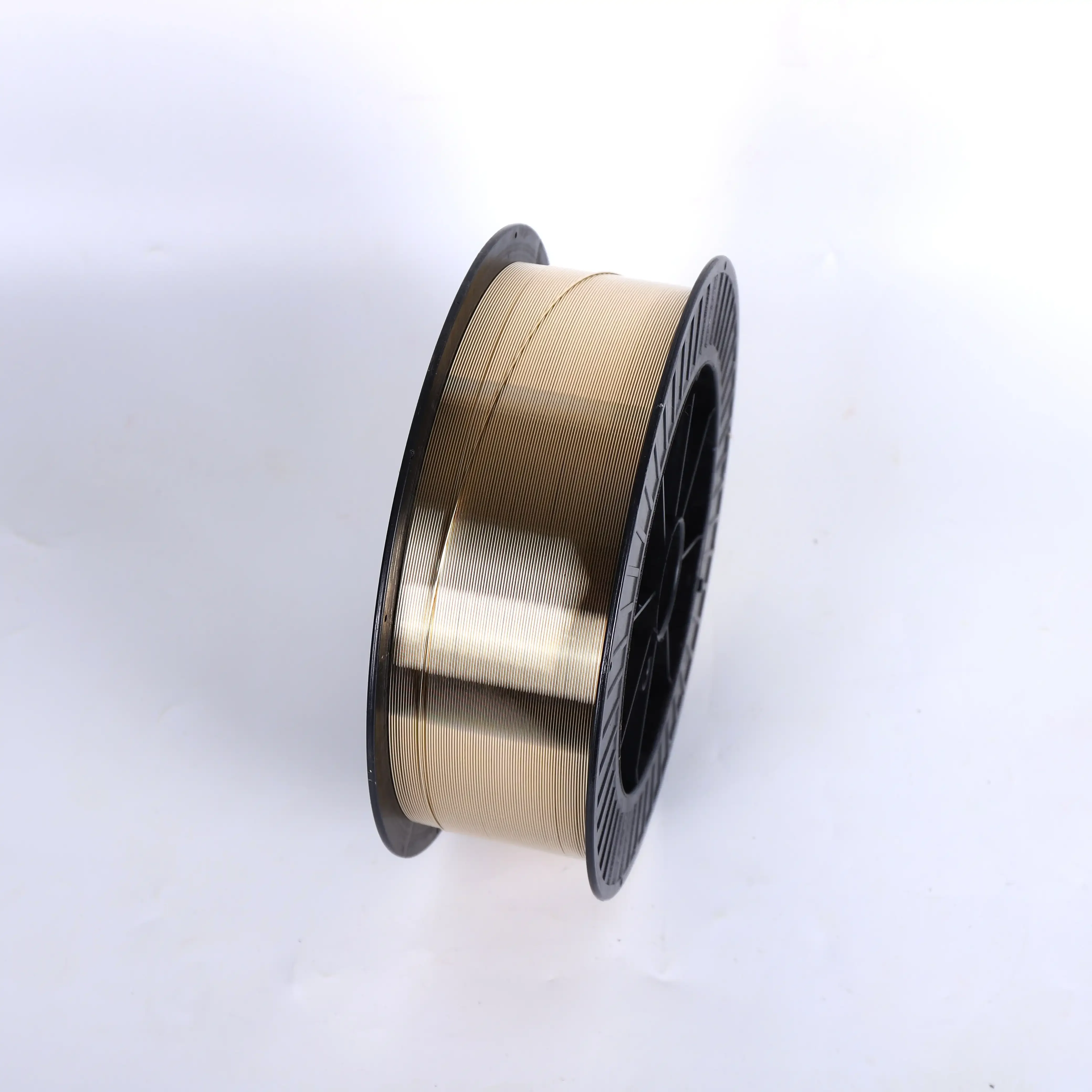

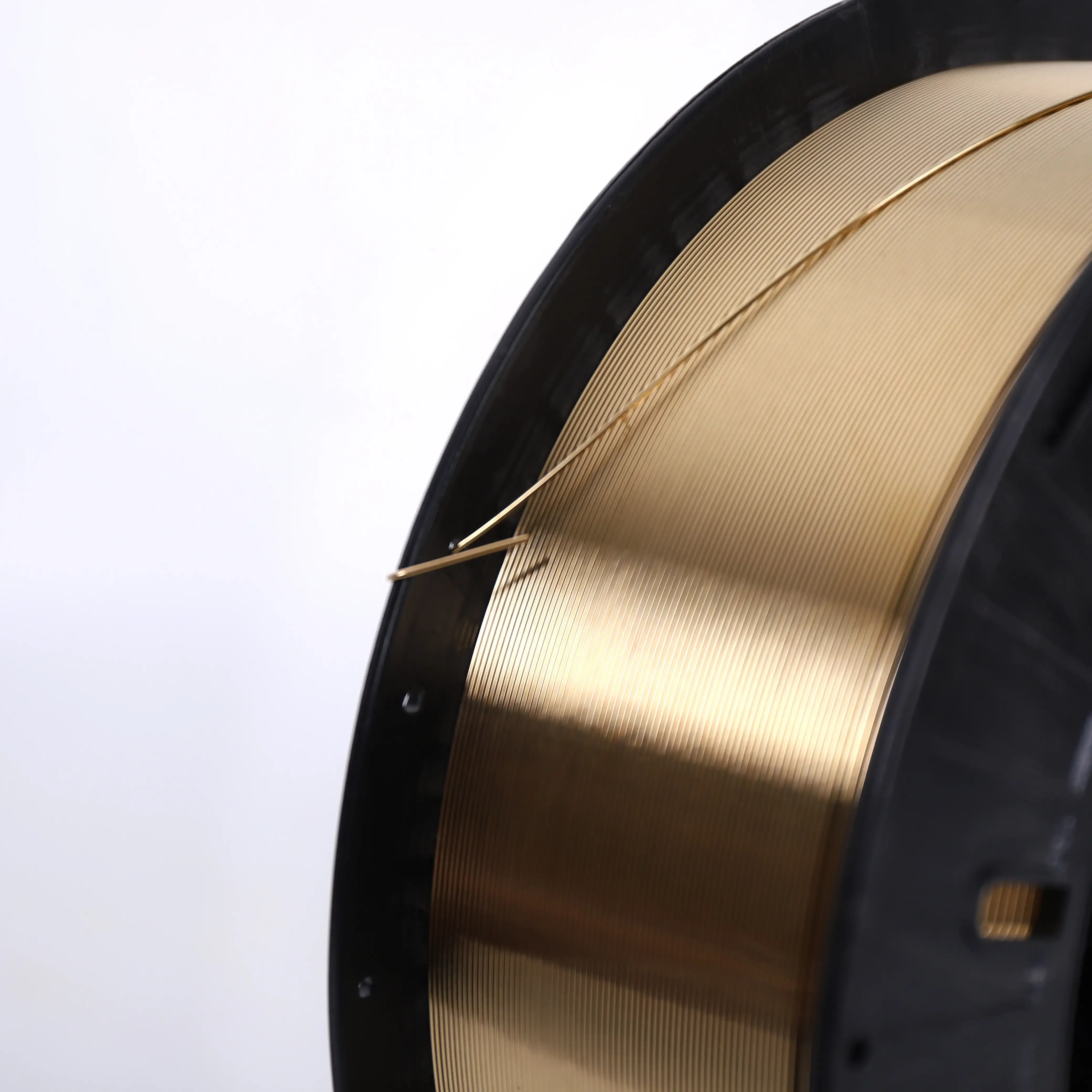

Aluminum Bronze Wire ERCuAl A2 Copper Alloy Welding Wire

- Category: >>>

- Supplier: Tongling Hengwang Co. Ltd.

Share on (1601183971757):

Product Overview

Description

PRODUCTS DESCRIPTION

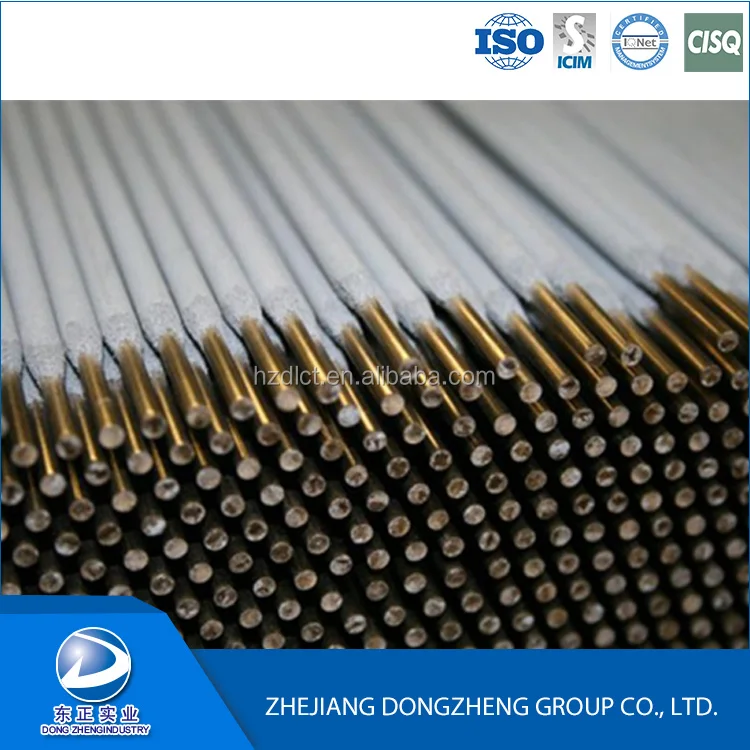

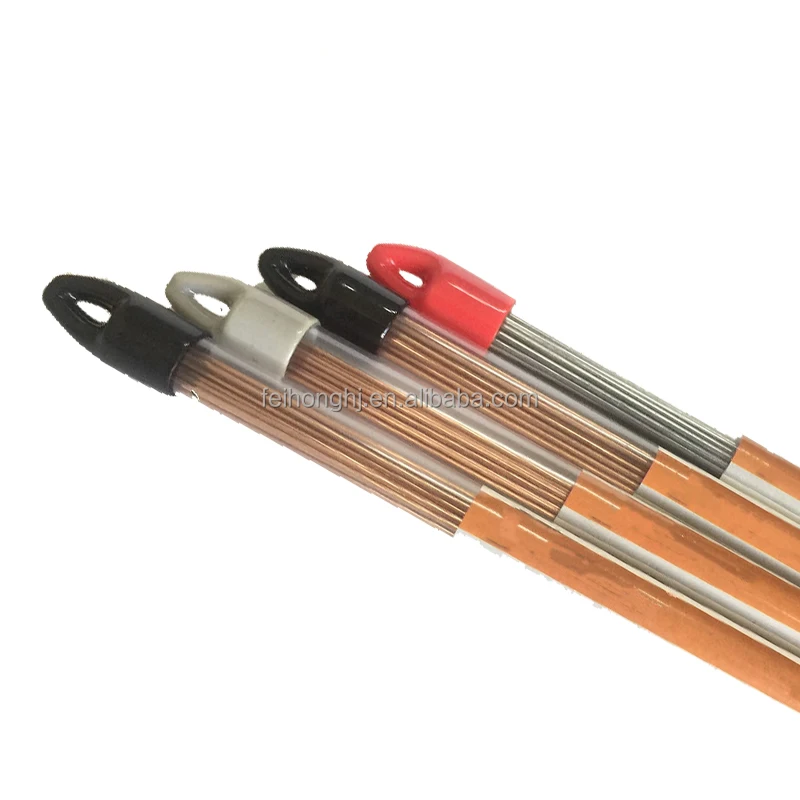

Aluminum Bronze Welding Rod S214 ERCuAl-A1 GTAW Argon arc welding

Aluminum Bronze A1 | ||

TRADE MARK | S214 | |

Equivalent to AWS | ERCuAl-A1 | |

Welding Method | GTAW Argon arc welding | |

Thermal conductivity | 65 W/m.K | |

Electrical conductivity | 7~9 S.m/mm² | |

Coefficient of thermal expansion | 17.0 10^-6/K(30-300℃) | |

Notched bar impact work | 100J | |

Standard | Class | Alloy | Chemical Composition | ||

ISO24373 | Cu6100 | CuAl7 | Cu:bal. Al:6.0~8.5 Fe:~ Mn:0.5 Ni:~ Pb:0.02 Si:0.2 Sn:~ Zn:0.2 Other:0.4 | ||

GB/T9460 | SCu6100 | CuAl7 | Cu:bal. Al:6.0~8.5 Fe:~ Mn:max0.5 Ni:~ Pb:~ Si:max0.1 Sn:~ Zn:max0.2 Other:max0.5 | ||

GB/T9460 | SCu6100A | CuAl8 | Cu:bal. Al:7.0~9.0 Fe:~ Mn:max0.5 Ni:max0.5 Pb:max 0.02 Si:max0.2 Sn:max0.1 Zn:max0.2 Other:max0.2 | ||

BS EN14640 | Cu6100 | CuAl8 | Cu:bal. Al:6.0~9.5 Fe:0.5 Mn:0.5 Ni:0.8 Pb:0.02 Si:0.2 Sn:~ Zn:0.2 Other:0.4 | ||

AWS A5.7 | C6100 | ERCuAl-A1 | Cu:bal. Al:6.0~8.5 Fe:~ Mn:0.50 Ni:~ Pb:0.02 Si:0.10 Sn:~ Zn:0.2 Other:0.50 | ||

DIN1733 | 2.0921 | SG-CuAl8 | Cu:bal. Al:7.5~9.0 Fe:max0.5 Mn:max1.0 Ni:max0.8 Pb:max0.02 Si:max0.2 Sn:~ Zn:max0.2 Other:max0.40 | ||

Introduction

Perfect for welding of pure and austenitic steel sheet. Maintains good temperament flow and creats seamless welding line. Suggested for the butt joining welding of copper with steel, particularly suitable for machinery and shipbuilding industry. Pulsed argon arc welding is recommended for multilayer hard facing on steel.

Physical Properties and Mechanical Properties | ||

Solids-Temperature | 1030℃ | |

Liquids-Temperature | 1040℃ | |

Density | 7.7kg/dm² | |

Tensity Strength | 380~450N/mm³ | |

Elongation | 40~45% | |

Brinell Hardness | 100HB | |

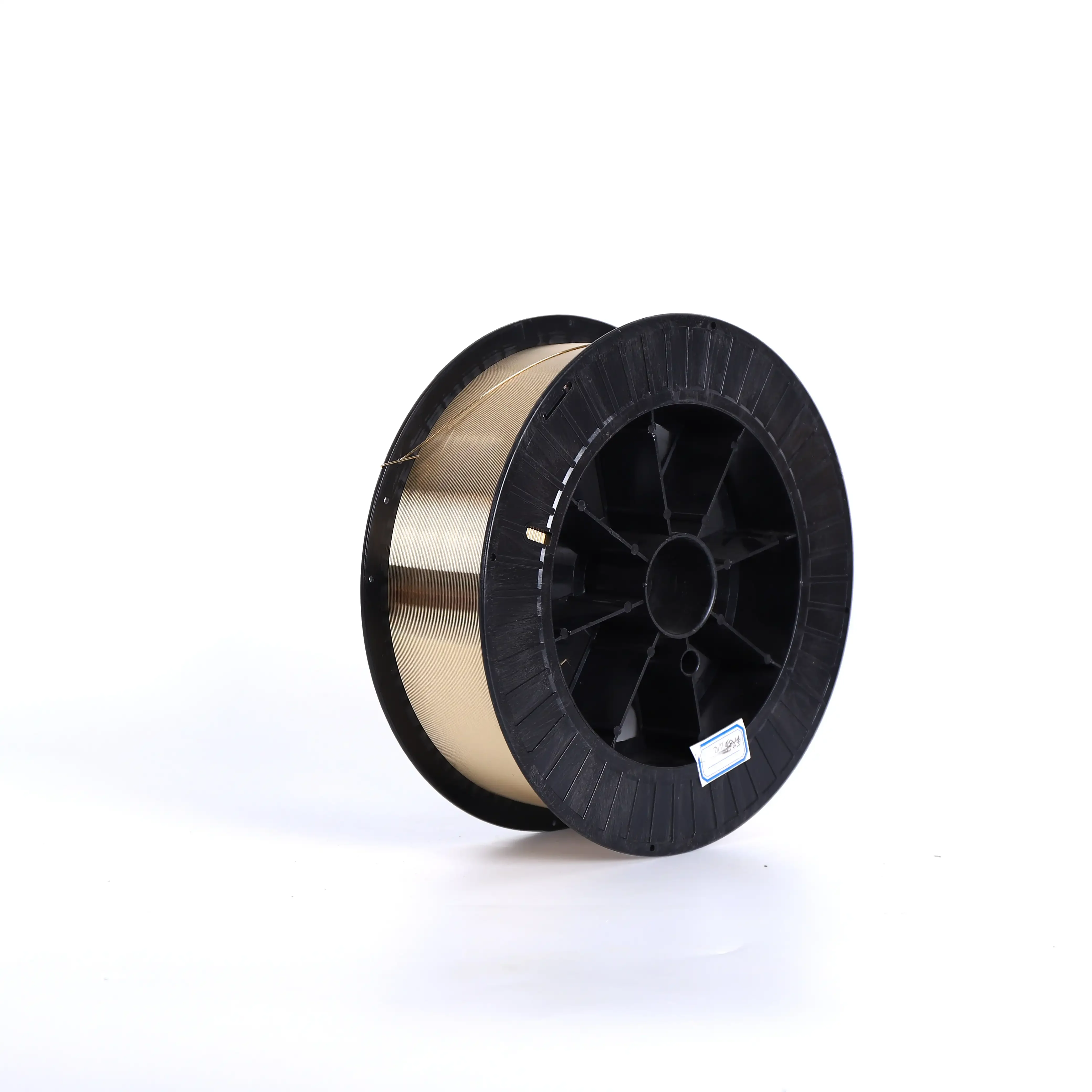

PACKING DETAILS

A spool in a carton box

Can be customized according to customer needs

1000kgs inner a wooden case

Can be customized according to customer needs

Loading and transporting to the port.

Can be customized according to customer needs

ABOUT US

Anhui Hengtai Welding Materials Co., Ltd. which was founded in 2007, is a professional manufacturer of copper and copper alloy welding materials.

Company adopted GB/T9460, BS EN14640, AWS, DIN standards,the production of copper, silicon bronze, aluminum bronze, tin bronze, white copper, brass, copper alloy series welding materials, and is widely used in automobiles, ships, engineering machinery, metallurgy, electric power,aviation,aerospace, oil and other fields. With years of communication with the majority of users and accumulated experience, the company provides each customerwith high-quality, reliable copper alloy series service,welding materials and thoughtful anddetailed pre-sale and after-sales “integrity-based, win-win cooperation” is the company’s corporate culture and purpose, we will cast a common dream with the spirit of craftsmen.

Company adopted GB/T9460, BS EN14640, AWS, DIN standards,the production of copper, silicon bronze, aluminum bronze, tin bronze, white copper, brass, copper alloy series welding materials, and is widely used in automobiles, ships, engineering machinery, metallurgy, electric power,aviation,aerospace, oil and other fields. With years of communication with the majority of users and accumulated experience, the company provides each customerwith high-quality, reliable copper alloy series service,welding materials and thoughtful anddetailed pre-sale and after-sales “integrity-based, win-win cooperation” is the company’s corporate culture and purpose, we will cast a common dream with the spirit of craftsmen.

RELATED PRODUCTS

Copper alloy welding wire CuSi3 Silicon Bronze

High quality Deoxidized copper welding wire CuSn1 for argon arc welding

Silicon Bronze Welding rod TIG ERCuSi-A for argon arc welding

Factory sales Tin Brass welding rod RBCuZn-A HS221

Deoxidized copper welding rod ERCu CuSn1 C18980

PRODUCTS APLLICATION

Our products are suitable for automobile casting, high pressure valve iron, hydraulic rod, marice casting, aerospace casting, ocean exploration, precision machinery, deep sea scale, marine water scale, high pressure valve, etc. Our company is a world leader in the field of copper alloys, and has made outstanding contributions to the field of copper alloy welding in the world. Our company has been to Arabia, Dubai, Germany, the United States, France, the Middle East, and Vietnam for many times to conduct academic exchanges and promote the world. Development in the field of copper alloy welding.

FAQ

We Recommend

New Arrivals

New products from manufacturers at wholesale prices