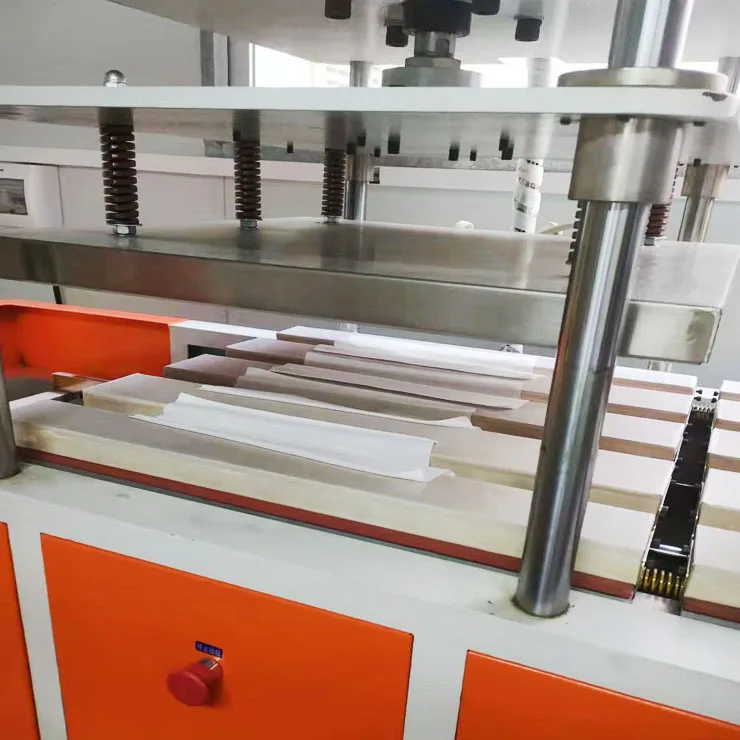

Side Bond Heating Press Machine

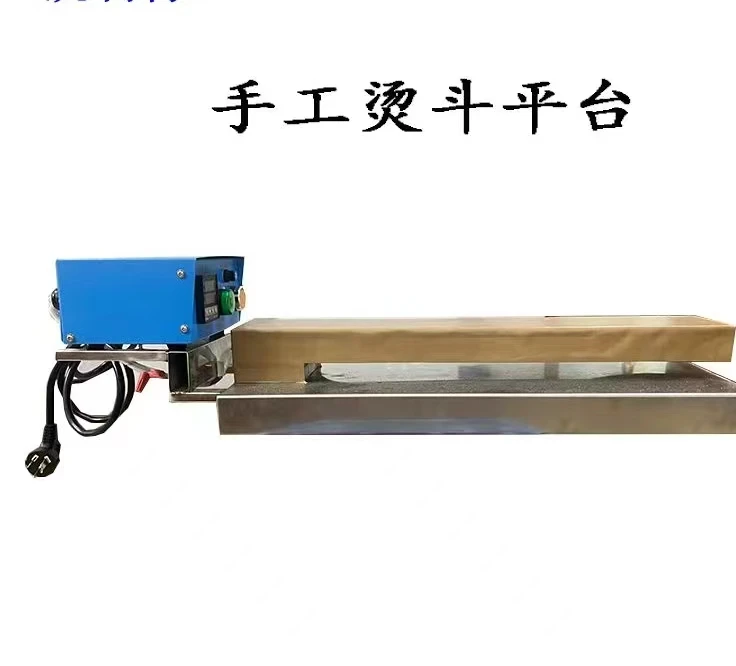

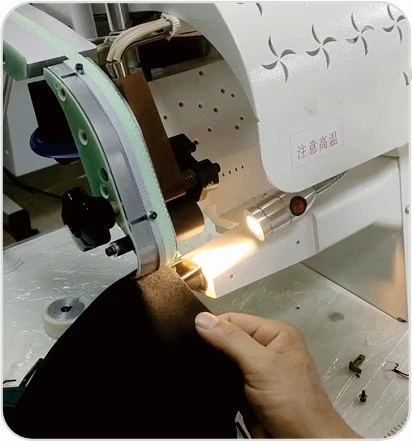

Function: Edge Bonding: Specifically designed for bonding the sides or edges of materials such as books, photo albums, and certain types of packaging. Spine Binding: Used in bookbinding to apply heat and pressure to the spine of the book, ensuring a secure bond for the pages. Key Features: Side Heat Platen: Designed to apply heat along the edges or sides of materials. Adjustable Clamps: Secure the material in place to ensure precise bonding. Temperature and Pressure Control: Provides the necessary adjustments to cater to different materials and bonding requirements.