Medium Flow Pressure Regulator 500psi 3000psi Single Stage Diaphragm Structure Drain Valves Oxygen Regulator CO2 Regulator

- Category: >>>

- Supplier: Shenzhen Wofly Technology Co. Ltd.Shenzhen Ltd.

Share on (1601187600765):

Product Overview

Description

Product Description

Product Features

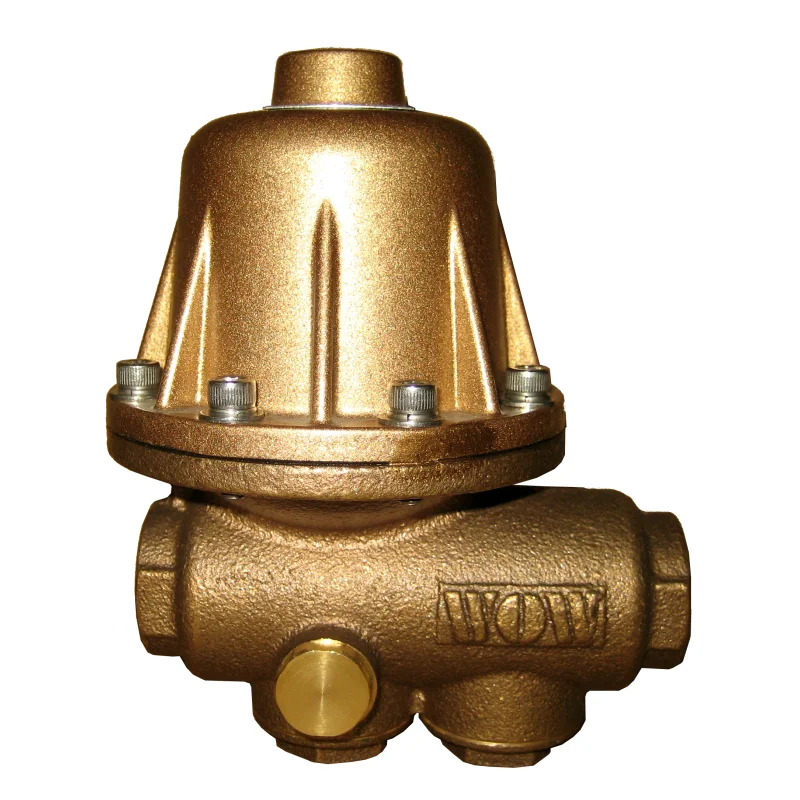

Single stage type diaphragm structure

The corrugated big diameter diaphragm improves sensitivity

Balanced valve core design decrease pressure supply effect

Can be used for corrosive and toxic gases

A 20um filter element is installed at the inlet

Oxygen environment application is optional

Balanced valve core design decrease pressure supply effect

Can be used for corrosive and toxic gases

A 20um filter element is installed at the inlet

Oxygen environment application is optional

Specification

item | value |

Application | General |

Port Size | 1/2 |

Warranty | 1 year |

Place of Origin | China |

Hunan | |

Model Number | WR12 |

Power | Hydraulic |

Temperature of Media | Normal Temperature |

Brand Name | AFKLOK |

Structure | Pressure Reducing |

Media | Corrosive and toxic gases,O2 |

Customized support | OEM, ODM |

Material | 316L SS |

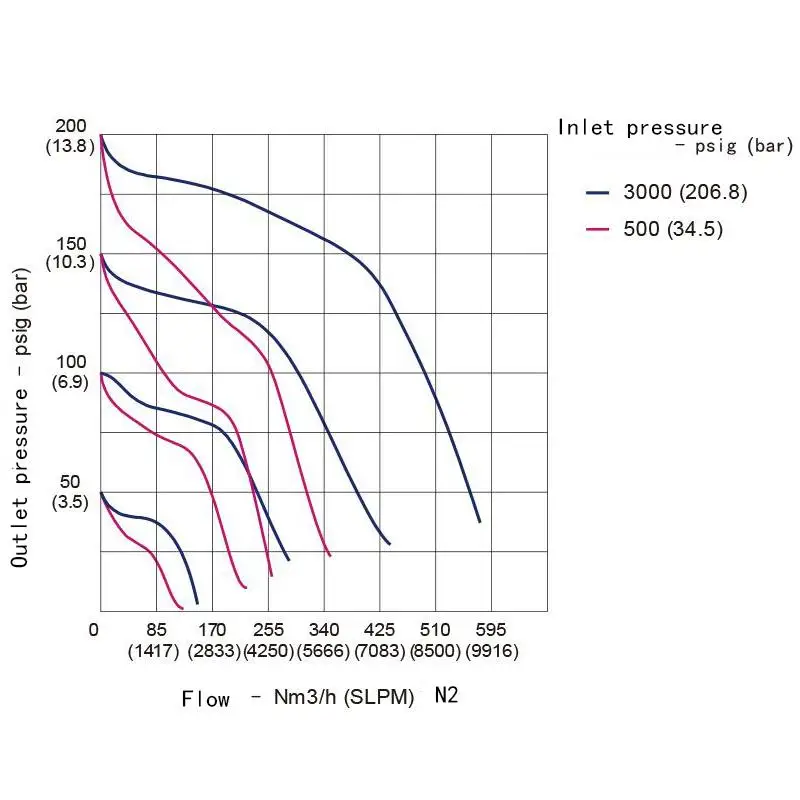

Max.inlet pressure | 500psig / 3000psig |

Output Pressure Range | 0~30,0~60,0~100,0~150,0~250,psig |

Certificate | ISO 9001 CE |

Valve seat | PCTFE |

Standard or Nonstandard | Standard Valve |

Diaphragm | Hastelloy |

Filter element | 316L |

Working temperature | -40℃~+60℃(-40℉~+140℉) |

Cv | 1.0 |

Packing & Delivery

Packing details : Export packing

Double plastic bags with internal vacuum and external plastic sealing+corrugated carton+ cardboard boxes+wooden pallet

Technical services are available 24H/D.

Application areas:Chemical Processes,Fuel Cell,Welding,Semiconductor material,CVD/PVD, Lithium battery, Solar Photovoltaic, LCD/LED panel, Hydrogen energy.

Company Profile

WOFLY is a leading Manufacturer, Supplier and Exporter of a wide range of gas equipements, available under the brand name AFK. Wofly's success yields from high-quality, innovative products, exceptional customer service, and unequaled technical expertise in the gas& oil industry.

WOFLY offers an extensive line of components including tube fittings, control valves, shut-off and solenoid valves, pressure relief and regulators.Through the years we have learned how to properly match the gas regulation equipment with the application. Using the proper equipment for the job eliminates problems such as contamination, pressure variances, safety issues, and equipment mismatch.

WOFLY offers an extensive line of components including tube fittings, control valves, shut-off and solenoid valves, pressure relief and regulators.Through the years we have learned how to properly match the gas regulation equipment with the application. Using the proper equipment for the job eliminates problems such as contamination, pressure variances, safety issues, and equipment mismatch.

FAQ

1. Who are we?

We are based in Guangdong, China, start from 2011,sell to Domestic Market(50.00%),Southeast Asia(14.00%),North America(8.00%),Northern Europe(8.00%),Eastern Europe(5.00%),South Asia(2.00%),South America(2.00%),Western Europe(2.00%),Southern Europe(2.00%),Central America(2.00%),Mid East(2.00%),Eastern Asia(1.00%),Oceania(1.00%),Africa(1.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Pressure Regulator, Instrumentation Valve, Gas Cabinet, Tube Fitting, Tubing

4. Why should you buy from us not from other suppliers?

We have a couple of years with professional engineers and dedicated technicians.can provide security products for you

5. What services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese

We are based in Guangdong, China, start from 2011,sell to Domestic Market(50.00%),Southeast Asia(14.00%),North America(8.00%),Northern Europe(8.00%),Eastern Europe(5.00%),South Asia(2.00%),South America(2.00%),Western Europe(2.00%),Southern Europe(2.00%),Central America(2.00%),Mid East(2.00%),Eastern Asia(1.00%),Oceania(1.00%),Africa(1.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Pressure Regulator, Instrumentation Valve, Gas Cabinet, Tube Fitting, Tubing

4. Why should you buy from us not from other suppliers?

We have a couple of years with professional engineers and dedicated technicians.can provide security products for you

5. What services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese

Class 100 clean workshop

Class 100 clean workshop is the workshop with the highest cleanliness, which is suitable for the production of products that require extremely high air cleanliness, such as integrated circuits and high-precision optical devices.

In a class 100 clean workshop, the number of dust particles and microorganisms with a diameter greater than 0.5µm per cubic unit of air shall not exceed 100. In order to meet this requirement, the workshop needs to adopt an air purification system to clean and maintain the environment regularly.

Class 1000 clean workshop

Class 1000 clean workshop is suitable for the production of products that require high air cleanliness, such as medical devices and medicines. In a class 1000 clean workshop, the number of dust particles and microorganisms with a diameter greater than 0.5µm per cubic unit of air shall not exceed 1000. Compared with the class 100 clean workshop, the cleanliness requirement of the class 1000 clean workshop is relatively low, but effective air purification measures are still needed to ensure the dust-free and clean production environment.

Production Advantages

1. Clean workshop assembly: All products have been assembled in 100-grade and 1000-grade clean workshops, and 100% of them have passed the helium seal test and functional test before leaving the factory.At present, Wofly has built 100-grade (over 100m2) and 1000-grade(over 500m2) dust-free workshops.

2.Our products are packaged for export, if the goods are damaged in transit due to packaging problems, we offer free exchange service.

3.Surface roughness :Wofly's EP-grade product Surface roughness reached Ra 0.13 um ,BA-grade product Surface roughness reached Ra 0.25 um.BA-grade products can be applied to gases below 6N purity,EP-grade products can be applied to 9N purity gases.

4.Clean process :

Standard (BA-Grade) : Regulators are cleaned in accordance with our standard cleaning and packaging specifications, and suffixes are not required when ordering.

Oxygen Cleaning (O2) : The specification for cleaning and packaging of products for oxygen environments meets ASTMG93 Class C cleaning requirements.

5.Production Processes: Using stainless steel material, rail welding and CNC machining technology, the products have excellent service life, corrosion resistance and oxidation resistance.

Maching workshop

Wofly's machining workshop has several CNC lathes, turning and milling compound and machining centers. Used for processing and producing spare parts such as valve body, nozzle, nut, plug, gasket, handle, coupling and so on. In addition, we are equipped with automatic deburring machines, ultrasonic cleaning machines and other peripheral equipment, which not only ensures the production efficiency of spare parts, but also improves the quality of spare parts. Spare parts are mainly used for pressure regulators, diaphragm valves,check valves,ball valves,needle valves,Tube fittings,ferrule connectors and VCR connectors.

The spare parts produced by machining have the advantages of high precision, high efficiency, high material utilization rate and strong stability, which is helpful to improve product quality, reduce production cost and meet customer needs.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices