froth pump flotation machine slurry pump pulp mine tailing high pressure foam pump

- Category: >>>

- Supplier: Shijiazhuang Deshi Pump Company Limited

Share on (1601193584794):

Product Overview

Description

AHF horizontal heavy duty high chrome froth foam slurry pump

Introduction:

Designed to handle heavy froth, the horizontal froth pump has a unique inlet and impeller design that is very successful where others fail. A large oversized inlet with a unique impeller inducer blade handles heavy froth and

higher viscosity dense slurries with ease. This horizontal froth pumps has proven valuable for very dense slurries where viscosity starts to become a pumping issue for the standard slurry pump.

Type | Flow rate | Head | Speed | Vanes | Inlet Diameter (mm) | Outlet Diameter (mm) | Max. Diameter (mm) | |

Q(m3/h) | L/S | |||||||

2C-AHF | 20.2-61 | 5.6-16.9 | 13-26.2 | 1300-1800 | 4 | 135 | 50 | 225 |

3C-AHF | 35.5-120 | 35.5-120 | 9.8-24 | 1000-1500 | 4 | 180 | 75 | 260 |

4D-AHF | 76.4-250 | 76.4-250 | 11.1-30 | 700-1100 | 4 | 280 | 100 | 390 |

6E-AHF | 210-530 | 210-530 | 17.4-40 | 600-800 | 4 | 350 | 150 | 560 |

The mining industry is a primary example of an operation plagued by froth and high viscosity problems. In the liberation of minerals from the ore, it is often floated through the use of strong flotation agents. Tough bubbles carry the copper, molybdenum or iron tails to be recovered and further processed. These tough bubbles create havoc with standard slurry pumps often causing the selection of overly large and inefficient pumps. The NAHF Froth Pump is sizes smaller and more efficient. The inducer impeller and oversized inlet very effectively assure the froth or viscous slurries get into the impeller allowing the pump to transport it to the next destination.

Lower power costs , reliable operation, greatly reduced surging and feed tank overflow make use of the froth pump more user friendly. Iron Ore Dressing Plant

Iron Ore Dressing Plant

Copper Concentration Plant

Gold Mine Concentration Plant

Molybdenum Concentration Plant

Potash Fertilizer Plant

Other Mineral Processing Plants

Other industries

AHF Impeller Part No.

CAHF2056QU1A05

DAHF3056QU1A05

EAHF4056QU1A05

FAHF6056QU1A05

FAHF8056QU1A05

STAHF10056QU1A05

AHF Throatbush Part No.

AHF Throatbush Part No.

CAHF2083A05

DAHF3083A05

EAHF4083A05

FAHF6083A05

FAHF8083A05

STAHF10083A05

Motor Drive Type:

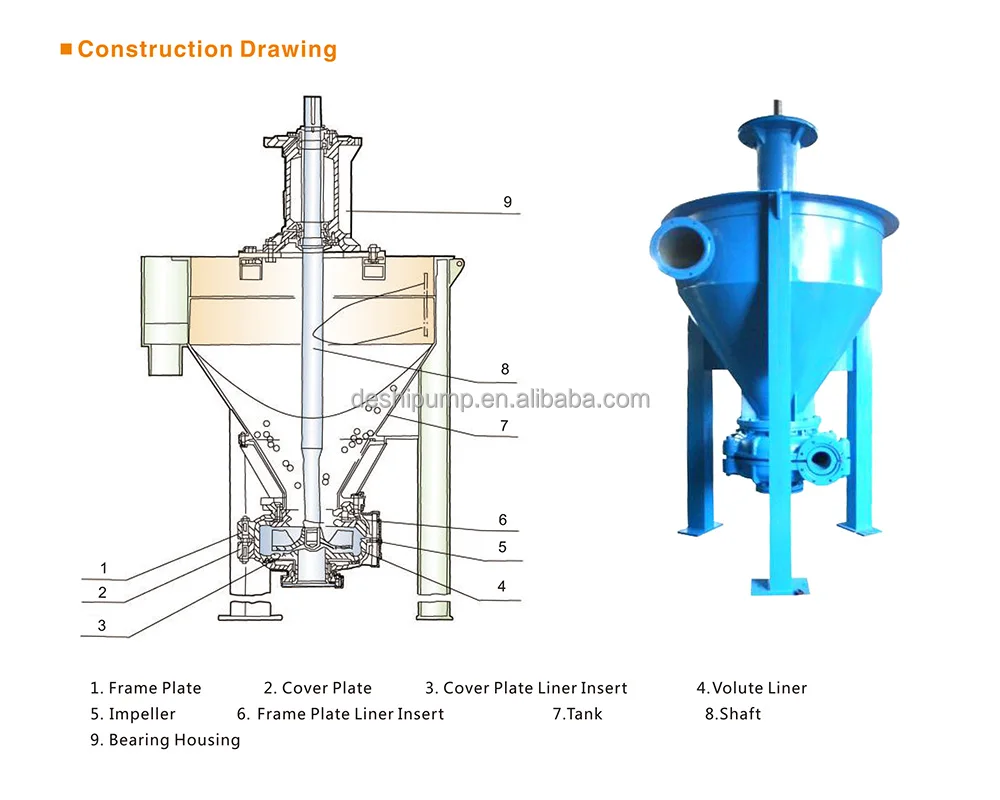

AF Vertical heavy duty high chrome rubber wear parts froth foam slurry pump

AF series vertical froth pump(foam pump) is widely used in metallurgy, mining, coal, chemical and other industries. It is suitable for conveying abrasive slurry containing froth(foam). This series of pumps can effectively eliminate foam in slurry when working. It can still work normally in case of insufficient incoming materials, especially suitable for various flotation processes.

Overview:

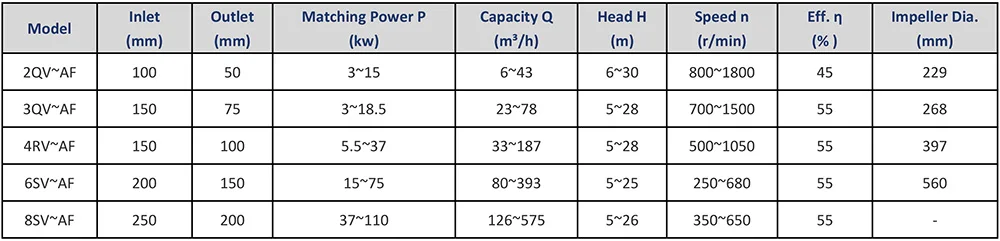

1. Name: AF Vertical Froth Pump

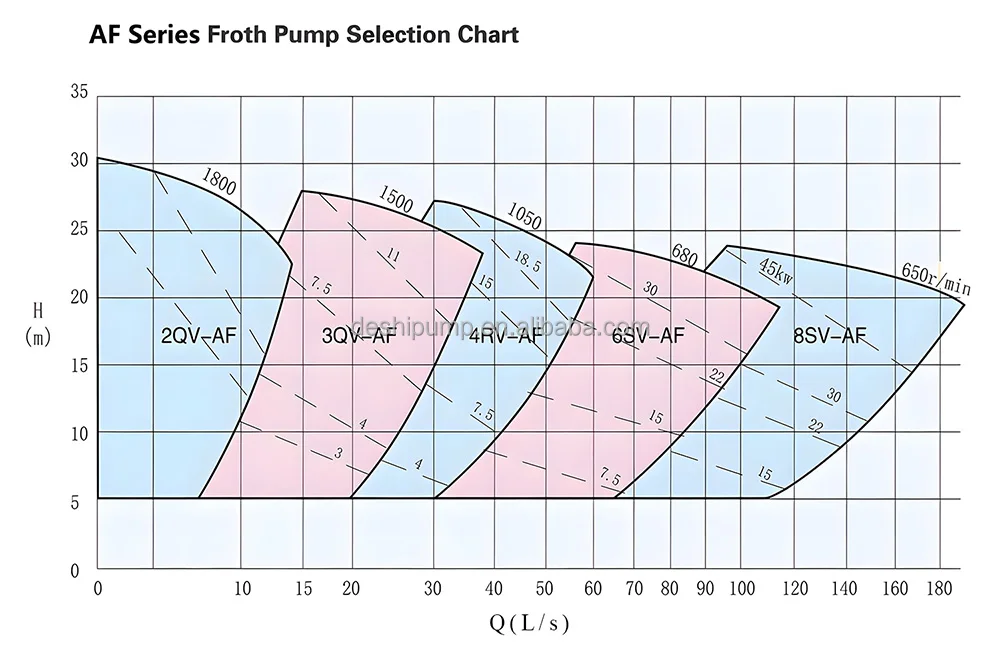

2. Model: 2QV-AF to 8SV-AF

3. Pump Type: Vertical centrifugal slurry pumps

4. Drvie Type: BD/DC

5. Power: Motor

6. Discharge Size: 50mm-150mm

7. Capacity: 7.2m3/h-393m3/h

8. Head: 5m-30m

Advantages:

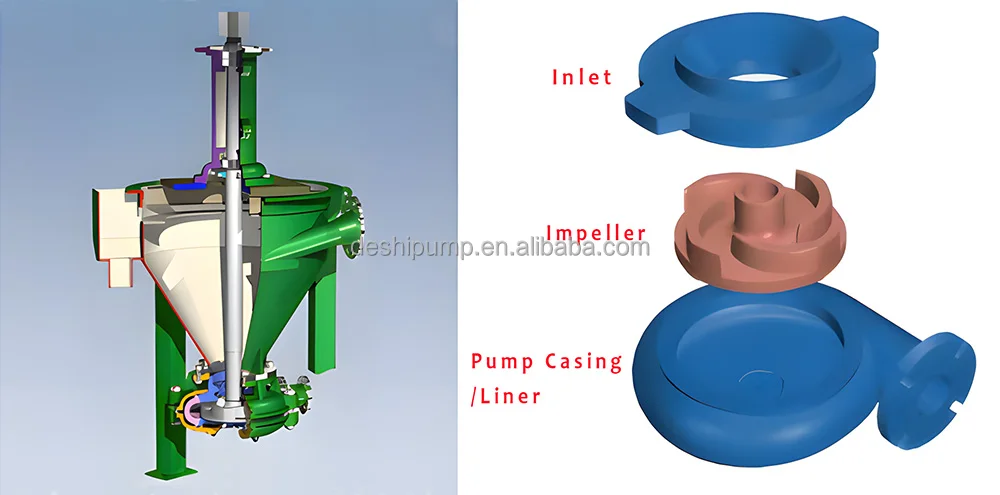

1. This type of pump is used in the SP type bearing assembly. The bearing body is installed with a motor base or motor frame, which can be directly or indirectly driven. The pulley can be easily replaced to change the pump speed to meet the change of working conditions.

2. The hopper/tank is made of steel structure or stainless steel, steel lined with rubber, etc. And it is equipped with a tangential feed inlet and overflow box. The overflow box can easily send the excess incoming materials back to the discharging pool. The tangential inlet can make the materials quickly enter the pump and eliminate some foam.

3. The pump head structure is double casing structure. According to the different slurry, the wear parts can be chosen: rubber or high chrome alloy.

Drive type: DC direct drive, BD vertical belt drive, etc.

Design Features:

√ AF rubber lined and hard metal vertical froth pumps were designed as one integrated unit for flexible layout and simple installation.

√ The pump, pump sump and driver are integrated in one self contained unit.

√ Simple to install and connect.

√ No alignment or special foundations needed.

√ The design ensures minimum maintenance and eliminates any requirement for water flushing.

√ Impeller clearance is maintained by external axial adjustment of the shaft/bearing assembly.

AF Froth pump Performance Parameters

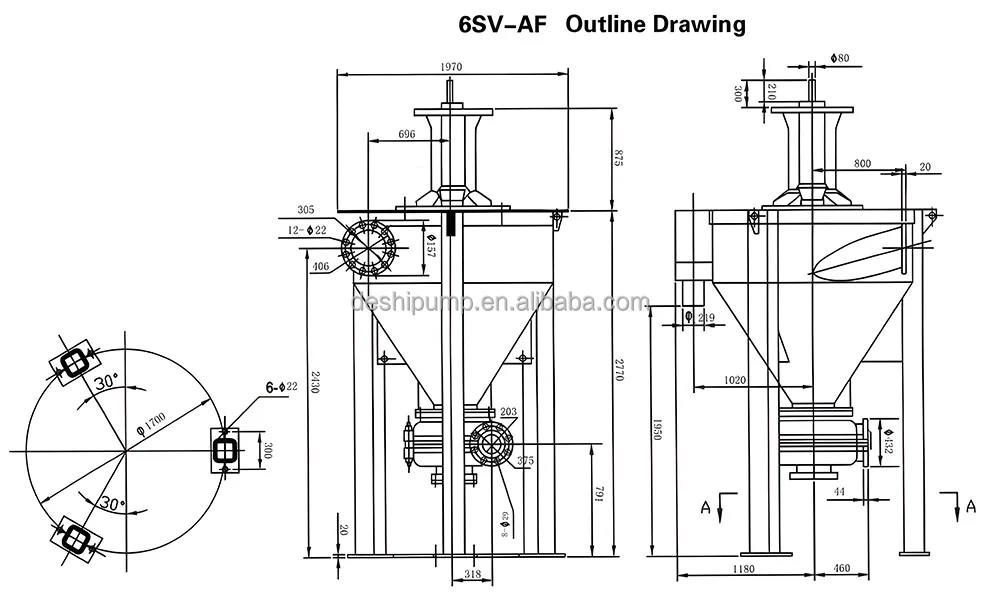

Froth Pump Outline Size(6SV-AF)

Assembly Workshop

Packaging & Shipping:

Applications Case:

Our main products:

Note: The displayed prices are for reference only, and the final price should be subject to mutual negotiation.

Welcome to contact us any time for more details.

Your inquiry or advice will get our prompt attention and response !

We Recommend

IS Series Irrigation Diesel Water Pump for Sale

Non Clogging Dry Prime Sewage Water Diesel Engine Pump Dewatering Pump

New Arrivals

New products from manufacturers at wholesale prices