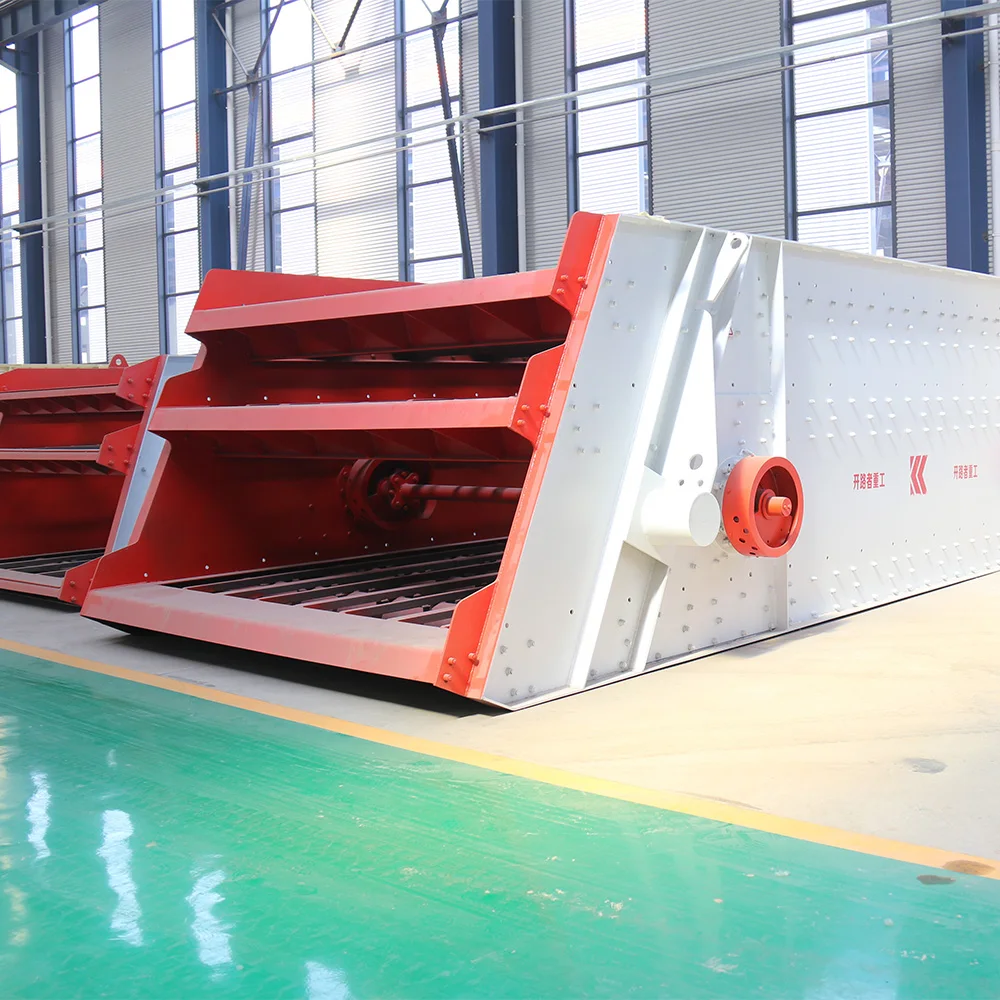

Vibrating Screen for Sand Gravel for Stone Crusher Sieving machine sand

- Category: >>>

- Supplier: Zhengzhou Huaye Heavy Industry & Machinery Co. Ltd.

Share on (1601195143215):

Product Overview

Description

Product Overview

YK SERIES HIGH PERFORMANCE ROUND VIBRATION SIEVE

TThe motion trajectory of a circular vibrating screen is circular, and the circular vibrating screen performs circular motion, which is a new type of vibrating screen with multiple layers and high efficiency. The circular vibrating screen adopts a cylindrical eccentric shaft

Exciter and eccentric block adjustment amplitude, long material screening flow line, multiple screening specifications, specially designed for screening materials in quarries, can also be used for mining, coal selection, and selection

Used for product classification in mining, building materials, power and chemical industries, it has the characteristics of reliable structure, strong excitation force, high screening efficiency, low vibration noise, durability, easy maintenance, and safe use

Exciter and eccentric block adjustment amplitude, long material screening flow line, multiple screening specifications, specially designed for screening materials in quarries, can also be used for mining, coal selection, and selection

Used for product classification in mining, building materials, power and chemical industries, it has the characteristics of reliable structure, strong excitation force, high screening efficiency, low vibration noise, durability, easy maintenance, and safe use

FEATURES AT A GLANCE

1. Using block eccentricity as the excitation force, the excitation force is strong.

3. The sieve machine has a simple structure and convenient and fast maintenance.

4. Using tire couplings, flexible connections, and smooth operation.

5. Adopting a small amplitude, high frequency, and large inclination structure, the machine has high screening efficiency, maximum processing capacity, long service life, low power consumption, and low noise.

PRODUCT SPECIFICATIONS

Model | Layers | Sieve area(㎡) | Mesh size (mm) | Max feeding size(mm) | Capacity(t/h) | Vibrating frequency(r/min) | Double amplitude (mm) | Motor power (kw) | Weight (t) |

2YK1235 | 2 | 4.2 | 5-50 | 80 | 15-100 | 800-970 | 8 | 5.5 | 3.2 |

3YK1235 | 3 | 4.2 | 5-50 | 80 | 30-100 | 800-970 | 8 | 7.5 | 4.4 |

2YK1545 | 2 | 6.75 | 5-50 | 100 | 50-180 | 800-970 | 8 | 15 | 5.3 |

3YK1545 | 3 | 6.75 | 5-50 | 100 | 50-210 | 800-970 | 8 | 15 | 6.1 |

4YK1545 | 4 | 6.75 | 5-50 | 100 | 50-240 | 800-970 | 8 | 18.5 | 6.9 |

2YK1860 | 2 | 10.8 | 5-80 | 200 | 50-330 | 800-970 | 8 | 22 | 8 |

3YK1860 | 3 | 10.8 | 5-80 | 200 | 50-360 | 800-970 | 8 | 22 | 8.6 |

4YK1860 | 4 | 10.8 | 5-80 | 200 | 100-400 | 800-970 | 8 | 30 | 9.2 |

2YK2160 | 2 | 12.6 | 5-100 | 200 | 100-430 | 970 | 8 | 30 | 8.8 |

3YK2160 | 3 | 12.6 | 5-100 | 200 | 100-460 | 970 | 8 | 30 | 9.45 |

4YK2160 | 4 | 12.6 | 5-100 | 200 | 120-460 | 970 | 8 | 30 | 10.9 |

2YK2470 | 2 | 16.8 | 5-100 | 200 | 150-500 | 970 | 8 | 37 | 9.63 |

3YK2470 | 3 | 16.8 | 5-100 | 200 | 150-550 | 970 | 8 | 37 | 11.5 |

4YK2470 | 4 | 16.8 | 5-100 | 200 | 180-600 | 970 | 8 | 37 | 12.78 |

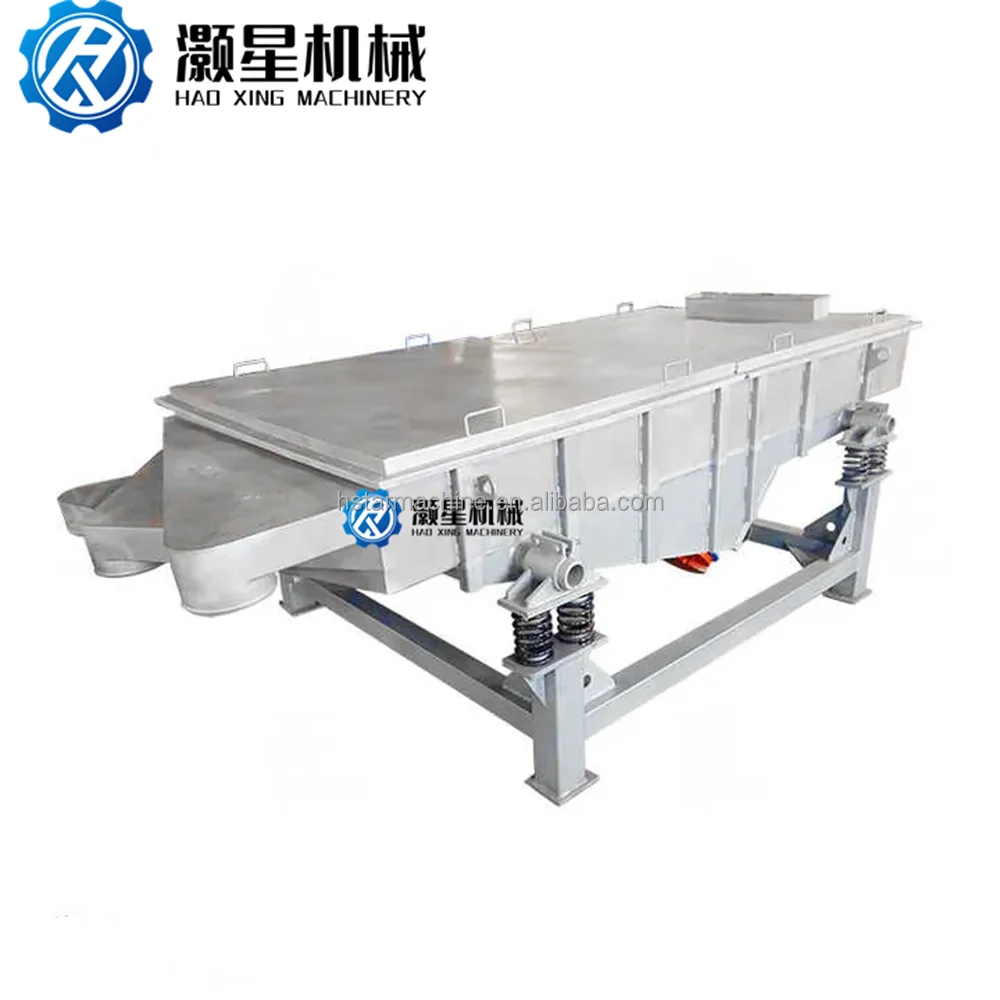

SIMILAR PRODUCTS

Product advantages

Business Cooperation

We sincerely welcome every valued client from home and abroad to visit our company and enter into long term business relationship with every friend.

FAQ

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to

quantity.

Q3: What is your payment method?

A: 30% of total price should be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery.

Q4: What Information should customers give us, So that we can be able to provide you suitable quotation and service.

What minerals are you separating?

What's the maximum size of your raw minerals?

How much capacity do you need per hour for your project?

Q5: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of crusher equipments is one year. and we will supply the spare parts for you at lowest cost.

Q6: If I need the complete crushing plant can you help us to build it?

A: Yes, we can help you combine a complete crushing line and give you related professional advices as long as you need. We had

already build many mining projects in China & Overseas.

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to

quantity.

Q3: What is your payment method?

A: 30% of total price should be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery.

Q4: What Information should customers give us, So that we can be able to provide you suitable quotation and service.

What minerals are you separating?

What's the maximum size of your raw minerals?

How much capacity do you need per hour for your project?

Q5: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of crusher equipments is one year. and we will supply the spare parts for you at lowest cost.

Q6: If I need the complete crushing plant can you help us to build it?

A: Yes, we can help you combine a complete crushing line and give you related professional advices as long as you need. We had

already build many mining projects in China & Overseas.

We Recommend

Electro Vibrating Feeder Conveyor and Vibrating Screen

$3,200.00-3,500.00

Battery Carbon Powder Recycle Ultrasonic Vibrating Sieve Machine

$1,800.00-2,000.00

New Arrivals

New products from manufacturers at wholesale prices