Good price for monazite concentrating equipment,monazite concentration machine

- Category: >>>

- Supplier: Ganzhou Gelin Mining Machinery Co. Ltd.

Share on (1601195439098):

Product Overview

Description

Good price for monazite concentrating equipment,monazite concentration machine

Application

The following is the operation flow that we make according to the customer's needs.

India 200 tons per hour zircon rutile ilmenite beach sand project.

Beach sand main contents:Gold, Ilmenite, Rutile, Zircon, Tin, Hematite, Magnetite, Andalusite, Quartz, Corindone, Atlri, Garnet, Monazite, Tantalum&niobium etc.

Customer' target: remove magnetic minerals and get the high grade rutile, tin and Zircon, more important to high recovery gold ore.

We design the processing flowchart as below:

1. Use sand pump feed material directly to spiral separator. If there are some bigger stones in deep areas, can consider use trommel screen to separate out particles +2mm

2. Spiral separator:use two-stages spiral separator, first stage is for rough concentration, the middling from first-stage will go to second-stage to concentrate again to get high recovery ratio.

3. Most of the heavy fractions are magnetic minerals, so in order to remove clean as much as possible, it is better to firstly use our factory special designed four rollers wet magnetic separator to remove magnetite ilmenite and hematite and weak magnetic ore.

4. the gold and zircon and other non-magnetic minerals goes to shaking table for concentration, also use two stages shaking table for getting higher concentration effect.

5. after the electrostatic separator, can get rutile and other minerals, maybe still including some magnetic minerals, so use a high intensity dry process magnetic separator to remove the magnetic minerals again, the zircon will be more high grade up to 66% for sale a good price.

We design different process flowchart depends on customer's actual mining condition.

Product details

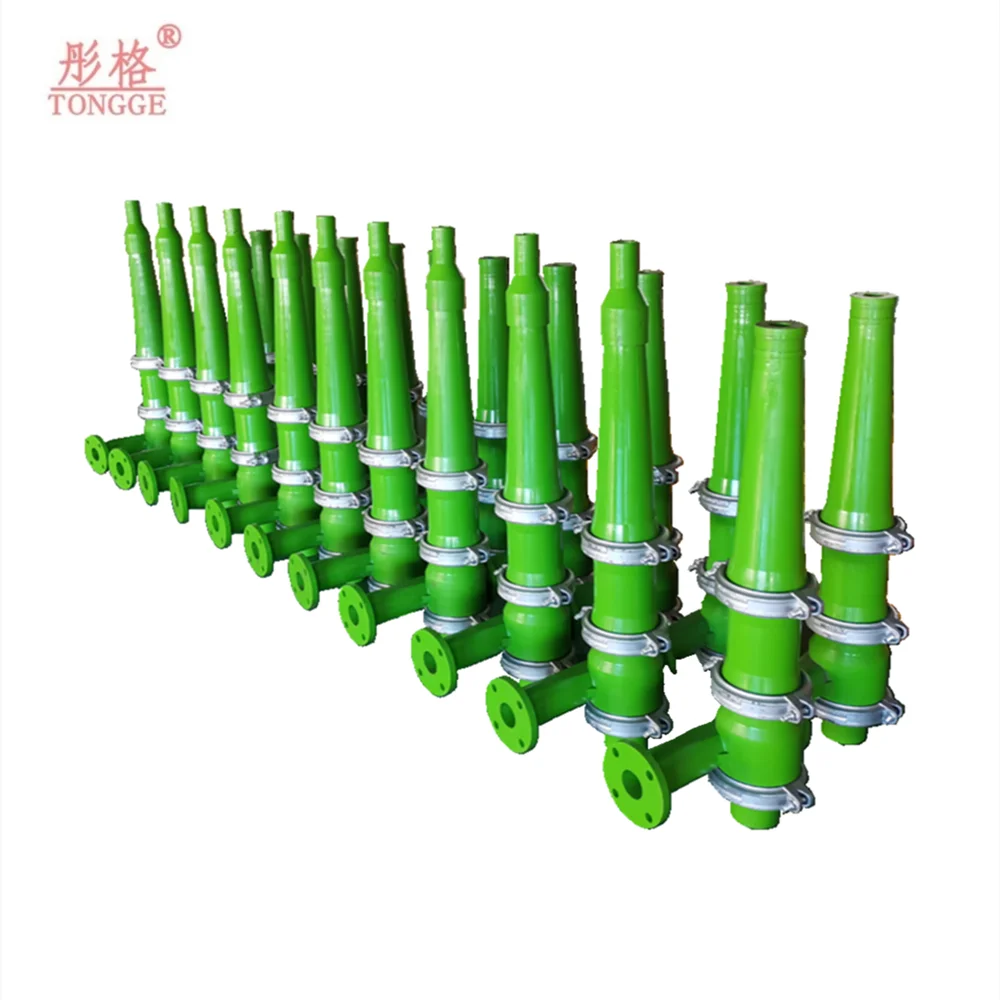

Spiral chute is a widely used gravity separator,it can be used for gold,copper,chrome,heavy minerals sand ores or processed rock ores.In the heavy minerals process,its function is disgarding sand.

| Modle | 5LL-2000 | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 | |

| Spiral Diameter(mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 | |

| Spiral Pitch(mm) | 1200 | 720/540 | 720/540 | 540/405 | 450/360 | 240/180 | |

| Max Spiral Start | 3 | 4 | 4 | 4 | 3 | 2 | |

| Max turn each start | 4 | 5 | 5 | 5 | 5 | 5 | |

| Feeding Particle Size(mm) | 4 | 3 | 2 | 2 | 2 | 2 | |

| Feeding Density(%) | 30-35 | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 | |

| Capacity(t/h) | 10-40 | 6-8 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.3 | |

| Capacity(t/h) | L(mm) | 2120 | 1560 | 1360 | 1060 | 700 | 460 |

| M(mm) | 2120 | 1560 | 1360 | 1060 | 700 | 460 | |

| H(mm) | 5600 | 5230 | 5230 | 4000 | 2600 | 1500 | |

| Weight(kg) | 900 | 800 | 600 | 400 | 150 | 50 | |

| Model | 6s-7.6 | 6s-4.08 | 6s-1.95 | 6s-0.5 | |||

| Deck type | Coarse ore deck | Fine sand deck | Slime deck | ||||

| Benefication Area(m2) | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | |

| Deck size | Length(mm) | 4450 | 4450 | 4450 | 3000 | 2100 | 1100 |

| Transmission end width(mm) | 1855 | 1855 | 1855 | 1320 | 1050 | 500 | |

| Concentrate end width(mm) | 1546 | 1546 | 1546 | 1100 | 850 | 430 | |

| Maximum feeding size(mm) | 2 | 0.5 | 0.15 | Sand-2 Slime-0.1 | Sand-2 Slime-0.074 | Sand-2 Slime-0.074 | |

| Feeding amount | 0.8-1.5ton/h | 0.8-1.5ton/h | 0.8-1.5ton/h | 0.4-1.5t/h | 0.3-0.8t/h | 0.05-0.2t/h | |

| Feeding density(%) | 25-30 | 20-25 | 15-25 | 10-30 | |||

| Stroke(mm) | 16-22 | 11-16 | 8-16 | 6-30 | 12-28 | 9-17 | |

| Frequency(F) | 45-220 | 53-250 | 60-280 | 210-320 | 250-450 | 280-460 | |

| Water added | 1-3t/h | 1-3t/h | 1-3t/h | 0.4-2t/h | 0.2-1t/h | 0.1-0.5t/h | |

| Transverse slope of deck | 2°30-4°30 | 1°30-3°30 | 1°-2° | 0-10° | 0-8° | 0-10° | |

| Longitudinal slope of deck | 1.4 | 0.92 | -- | -- | -- | -- | |

| Cross-section shape of deck | rectangular | saw-tooth | triangle | -- | -- | -- | |

| Motor power(kw) | 1.1 | 0.55 | |||||

Transmission mechanism | Eccentric linkage | ||||||

Successful case

Ganzhou Gelin Mining Machinery Co., Ltd is an over 30 years professional manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation, separation etc. in China. Gelin have a complete service system which can provide customer full service in mining field and after sales service.By now, Gelin’s equipments and services are exported to over 60 countries,include America, Russia, India, Africa, Brazil, Chile,South Africa,Zambia etc. Sincerely welcome customers to visit our factory.

Our factory is the leading mining equipments manufacturer who have over 30 years experience in mining field.We produce full sets mining equipments for processing and separating these ores in the following chart. Main equipments include Trommel, Rotary scrubber, Jig machine, Spiral chute, Shaking table, Magnetic separator, Electrostatic separator, Jaw crusher, Ball mill, Hammer crusher, Double roller crusher, Vibrating screen, Mercury amalgamation, Gold smelting furnace, Diamond washing machine, Gold pan, Drier machine and so on.

One Stop solution for beneficiation plant service

1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design and equipment, we also provide the infrastructure design; Electrical and pipeline system design, etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands.

1.Strict machine inspection before delivery;

2.Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3.Trace the status of the shipping until the products received;

4.Prepare required documents to let clients pass custom clearance;

5.Dispatch experts to carry out below service on site:

1) Installation & debug of the machinery

2) Train the first-line operators & technical personnel

3) Carry out any other service clients may need

6. Provide technical exchanging & spare parts for life-long term

Q: If I don’t know installation and commissioning,what should I do?

We Recommend

New Arrivals

New products from manufacturers at wholesale prices