Recommended Oxygen Generation Systems for Gold Leaching/Mine Sparging

- Category: >>>

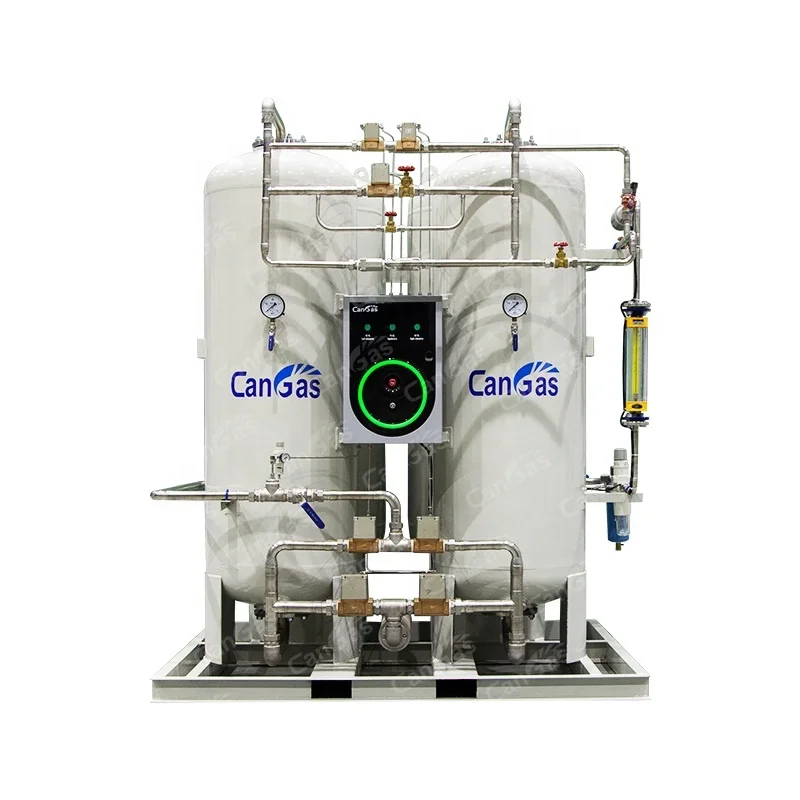

- Supplier: CAN GAS SYSTEMS COMPANY LIMITEDCAN LIMITED

Share on (1601196785433):

Product Overview

Description

Product Description

CAN GAS provides air separation products, air separation solutions, onsite solutions, gas solutions, oxygen production line, nitrogen production line by proven technology of PSA, VPSA, VSA, Membrane, Liquid, Cryogenic, Hydrolytic with over 20 years & over 28,000.00 ㎡ Manufacture Center & R&D Center. CAN GAS rugged, engineered oxygen generator is the safe and economical way to achieve O2 purity levels from 80% to 99.6%. CAN GAS on-demand oxygen generation systems are

designed to meet each customer’s specific purity, pressure and flow requirements for a fraction of the cost of delivered gas.CAN GAS oxygen container systems can be easily trucked to your location for complete turnkey operation.

We also offer an oxygen filling station and a complete line of accessories which is widely used in metal cutting, liquid O2

production, hospitals, medical applications, clinics, gas companies, field hospitals, and so on.

Oxygen Container Systems

Oxygen Filling Station/System

Oxygen Generation up to 95% Purity

Required Gas: Oxygen

Purity Range: 90 – 95%

SPECIFICATIONSOF CAN GAS CAPO-150 OXYGEN PRODUCTION LINE | ||||||

Main parts | PSA oxygen generator | Air compressor | Air filter | |||

Refrigerated Air dryer | Process oxygen tank | Oxygen booster | ||||

Desiccant air dryer | SMART AUTO CONTROL SYSTEM | Piping, supports, skids, instrumentation, others | ||||

Main performance parameters | Main performance parameters | 150Nm³/h@93% oxygen purity | 100% auto control | |||

Material required: air & electricity | Compressor & dryer are air cooled | 7*24 unattended | ||||

Oxygen pressure is customizable | Power consumption: ~200kW | 24 hours per day running: no problem | ||||

Maintenance | Filter elements: 4000hrs | Oil separator element: 8000hrs | Oil filter element: 8000hrs | |||

ZMS: 10 years | Oxygen sensor: 3 years | Oxygen booster oil: never | ||||

Seal kit of pneumatic valve: 5 years | No other Maintenance | Easy operations Low Maintenance | ||||

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double stage diaphragm oxygen booster with most reliable performance, no downtime, no troublesome.

4) Running in a high automatization and intellectualization,no pollution.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

CAN GAS PSA O2 PLANT

91.8% Response Rate

CAN GAS Liquid Nitrogen Plant

91.8% Response Rate

CAN GAS TRAILIER OXYGEN

91.8% Response Rate

We Recommend

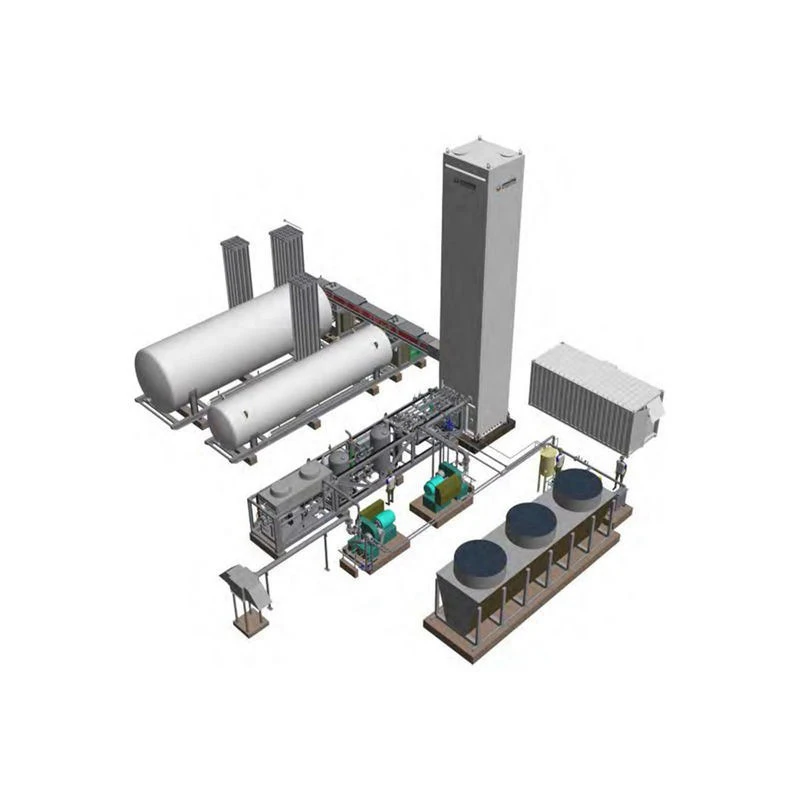

Cryogenic air Separation Unit Gas with Two Columns Oxygen Nitrogen Producing Manufacturers

New Arrivals

New products from manufacturers at wholesale prices