3rd Generation None Rising Resilient Seated Gate Valves Butterfly Valves

- Category: >>>

- Supplier: Shanghai Youwei Powder Equipment Co. Ltd

Share on (1601199188711):

Product Overview

Description

Product Description

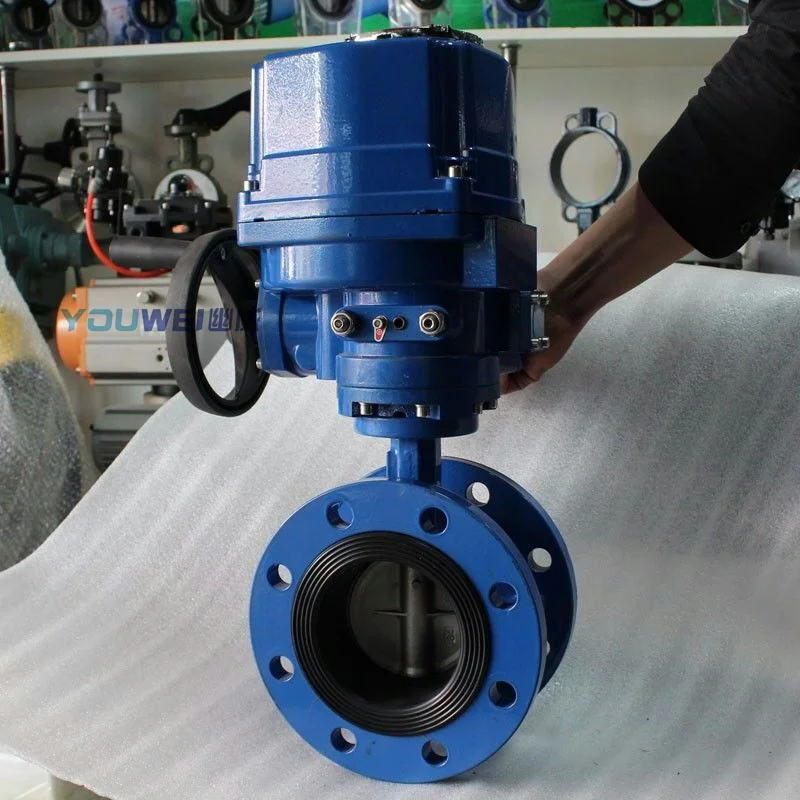

Butterfly valve, also known as the flap valve, is a simple structure of the regulating valve, can be used for low-pressure pipeline media switching control of the butterfly valve is the closing member (valve flap or butterfly plate) for the disc, rotating around the valve axis to achieve the opening and closing of a kind of valve.

Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, slurry, oil, liquid metals and radioactive media. Mainly in the pipeline to cut off and throttling role. Butterfly valve opening and closing member is a disc-shaped butterfly plate, rotating around its own axis in the valve body, so as to achieve the purpose of opening and closing or regulation..

Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, slurry, oil, liquid metals and radioactive media. Mainly in the pipeline to cut off and throttling role. Butterfly valve opening and closing member is a disc-shaped butterfly plate, rotating around its own axis in the valve body, so as to achieve the purpose of opening and closing or regulation..

FAQ

Butterfly valve is suitable for flow regulation. Since the pressure loss of butterfly valves in the pipeline is relatively large, the robustness of the butterfly plate to withstand the pressure of the pipeline medium when it is closed should also be considered. In addition, it is also necessary to consider the limitations of the working temperature borne by the resilient valve seat material at high temperatures. Butterfly valve structure length and overall height is small, fast opening and closing speed, and has good fluid control characteristics, butterfly valve structure principle is most suitable for the production of large diameter valves. When the butterfly valve is required to be used for flow control, the most important thing is to choose the correct size and type of butterfly valve so that it can work properly and effectively.

Recommend Products

Product Features

Dome Valve is Perfect Solution to Powder, Ash or Solid particles

1. Standardized Products & Parts are Easy to Be Installed Directly on SILO, & Replaced for Maintenance;

2. Dome Valve is Designed to Be Sealed And Completely Closed by Using Inflatable Gasket that is Inflated by Air Supplied, so Dome valve Torque is Very Low;

3.Air Injection and Ventilation is Controlled by Inflatable Gasket and Solenoid Valve to Minimize the Friction Between Gasket and

Spherical Cap;

Spherical Cap;

4. Gasket and Air are Utilized Simultaneously for high sealing.

Dome Valve is simple but perfect solution for your process

Dome valve is Opened and Closed Using a Pneumatically Operated Actuator and Supplying Air to Operate Actuator is Also

Provided to Inflate the Gasket and Spherical Dome is Seal Completely. Rotary system and Inflatable Gasket are Controlled

by PLC.

Provided to Inflate the Gasket and Spherical Dome is Seal Completely. Rotary system and Inflatable Gasket are Controlled

by PLC.

Dome Valves are Installed in Power plant, Mining/Mineral processing, Cement/Concrete plant(Pneumatic Conveying System), Storage silo, Chemical Plant etc.

Product Description

Dome Valve DN 200 is capable of handling powdery and granular materials like fly ash, bottom ash, boiler bed

sand and limestone. It is extremely reliable and easy to maintain, providing long maintenance intervals.

sand and limestone. It is extremely reliable and easy to maintain, providing long maintenance intervals.

Dome Valve is a high performance special valve and is used all over the world in Material Handling Systems in a wide range of industries. The dome valve closes also through the material, opening the material flow only a quarter turn from fully closed to fully open.

Dome Valve has a simple construction and automatically inflating sealing mechanism which operates with compressed air ensuring minimized wearing.

Dome Valve DN 200 Specification:

1. Air Pressure: 8 bar | 5. Pneumatic Actuator |

2. Dome Material: Carbon Steel | 6. Limit Valve |

3. Body: Carbon Steel | 7. PTFE coating for sealing surface |

4.High work temperature |

Equipment production process

Certifications

Company Information

Founded in 2011, Shanghai Youwei Powder Equipment Co., Ltd. is a production-oriented processing enterprise specializing in powder unpacking, conveying, weighing, metering, batching and packaging equipment manufacturing. The registered capital of the company is 12 million. The company has two processing bases in Zhangjiagang City and Qidong City, with a plant area of nearly 8,000 square meters.

For more than ten years, we have been deeply engaged in the field of material handling automation, and we have always been guided by customer needs, and have independently developed equipment such as small bag feeding station, ton bag unpacking machine, vacuum feeding machine, weighing and metering batching, ton bag packaging machine and so on. We have rich industry experience in the food ingredients industry, lithium battery cathode and anode industry, and pharmaceutical intermediates industry.

The company adheres to the spirit of integrity, pragmatism and innovation, and provides high-quality systematic solutions for all kinds of users with rich experience in technology development , and goes hand in hand with users to create a better future.

For more than ten years, we have been deeply engaged in the field of material handling automation, and we have always been guided by customer needs, and have independently developed equipment such as small bag feeding station, ton bag unpacking machine, vacuum feeding machine, weighing and metering batching, ton bag packaging machine and so on. We have rich industry experience in the food ingredients industry, lithium battery cathode and anode industry, and pharmaceutical intermediates industry.

The company adheres to the spirit of integrity, pragmatism and innovation, and provides high-quality systematic solutions for all kinds of users with rich experience in technology development , and goes hand in hand with users to create a better future.

Why Choose Us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices