Automatic PCB Vacuum Suction Loader for SMT Production Line Factory Price New Condition 1 Year Warranty SMEMA Compatible

- Category: >>>

- Supplier: Shenzhen Censtar Technology Co. Ltd.

Share on (1601199407870):

Product Overview

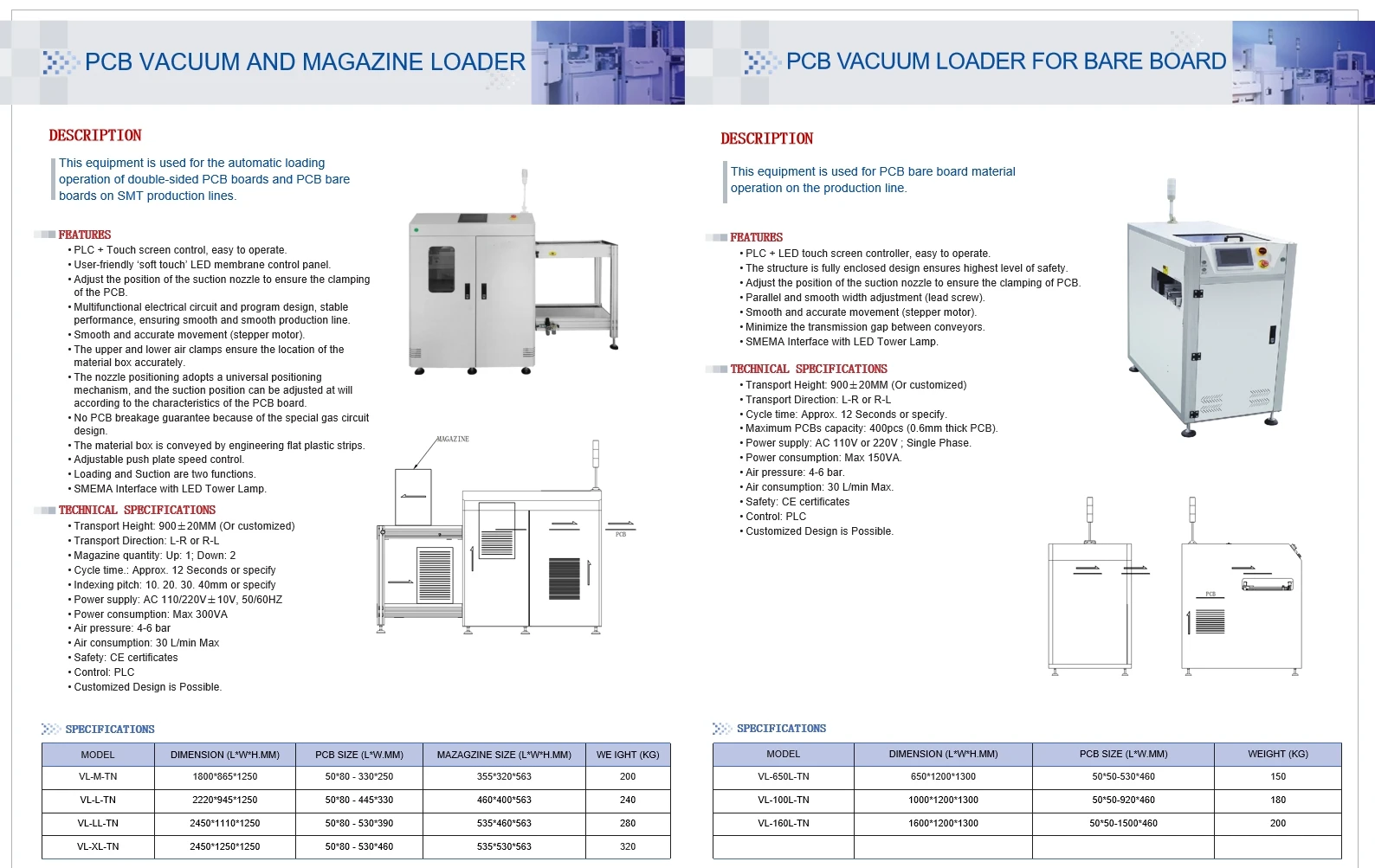

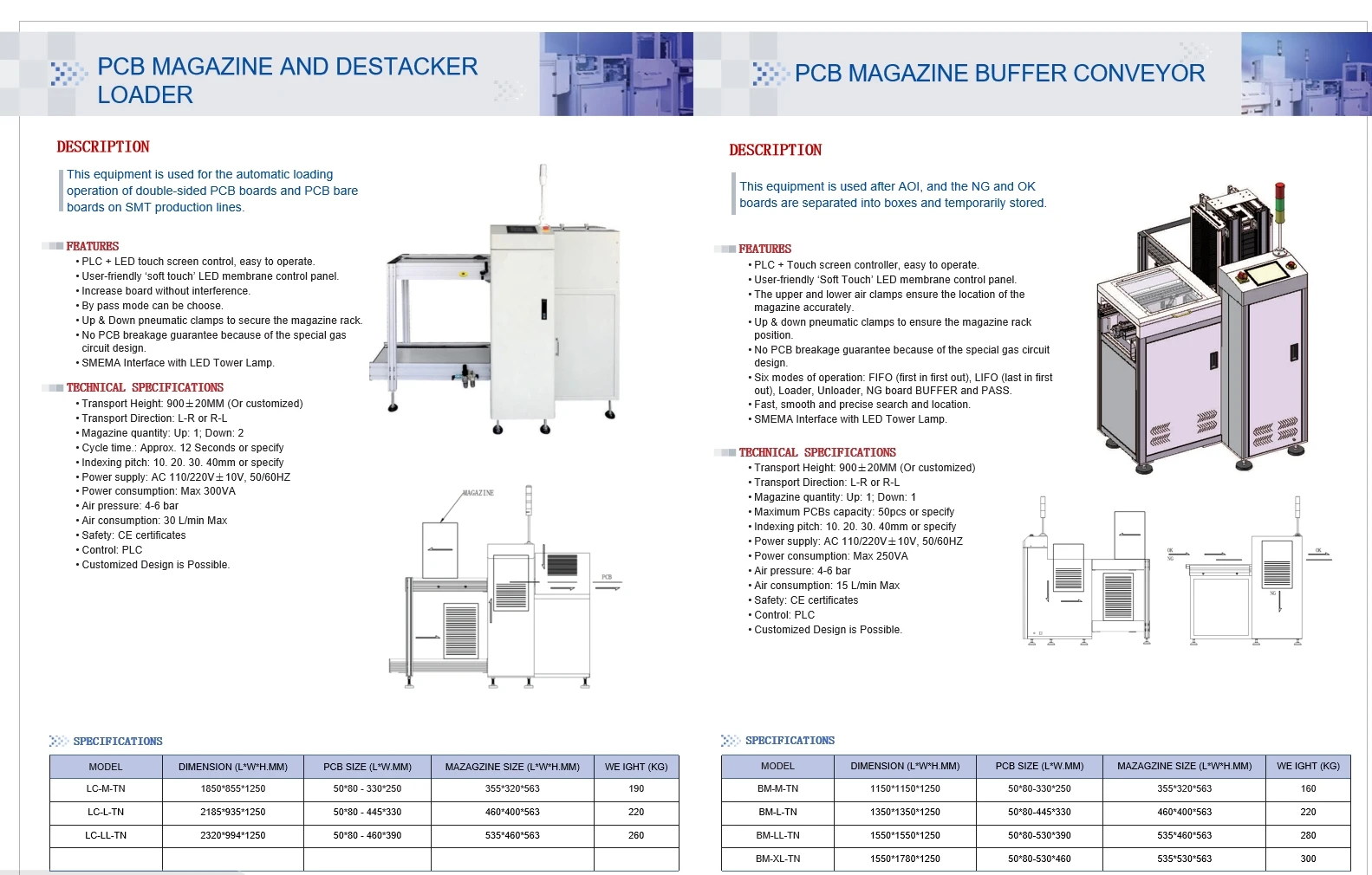

Description

Description

The vacuum loader is used to load bare boards for SMT production lines. The top PCB is lifted from stack and lowered onto belt segment. The PCB stack is manually loaded into the machine and the individual PCBs are handed over to the downstream system on a transfer conveyor.

Features

1. PLC program control.

2. Bare boards loader mode & By-pass mode selectable.

3. Complete the top safety visual window with interlock.

4. Adjustable vacuum nozzle positions provide a better way to hold the different-sized PCB.

5. Automatically position the shuttle distance and accurately release the PCB on the conveyor rail.

6. Sucking stability is improved by using a robust vacuum generator system.

7. Pre-warning limit alarm for stack empty.

8. A hand crank is used to adjust the rail width.

9. Use the friendly touchscreen panel.

10. SMEMA compatible.

2. Bare boards loader mode & By-pass mode selectable.

3. Complete the top safety visual window with interlock.

4. Adjustable vacuum nozzle positions provide a better way to hold the different-sized PCB.

5. Automatically position the shuttle distance and accurately release the PCB on the conveyor rail.

6. Sucking stability is improved by using a robust vacuum generator system.

7. Pre-warning limit alarm for stack empty.

8. A hand crank is used to adjust the rail width.

9. Use the friendly touchscreen panel.

10. SMEMA compatible.

Technical Parameters | ||||||||

Model | LV-650L-TN | LV-100L-TN | LV-160L-TN | |||||

PCB size(L*W) | 50*50-530*460mm | 50*50-920*460 | 50*50-1500*460mm | |||||

Dimension(L*W*H) | 650*1200*1300mm | 1000*1200*1300mm | 1600*1200*1300mm | |||||

Transport height | 900±20mm | |||||||

Transport direction | L-R or R-L | |||||||

Operation side | Front of the machine | |||||||

Fixed rail | Front of the machine | |||||||

Interface | SMEMA signal | |||||||

Conveyor belts | ESD flat belt | |||||||

PCB edge support | 4mm | |||||||

PCB thickness | 0.6mm-5mm | |||||||

Top/Bottom component clearance | Bottom 25mm or specify | |||||||

Maximum board weight | 2kg/PCB | |||||||

PCB Loading time | Approx 10 seconds | |||||||

PCB stock capability | 400pcs(0.6mm thick PCB) | |||||||

Control | PLC | |||||||

Power supply | AC220V/110V, 50/60 HZ, 1 phase | |||||||

Power consumption | 150VA max | |||||||

Air pressure | 4-6bar | |||||||

Air consumption | 30ltr/min max | |||||||

Weight | 150kg | 180kg | 200kg | 300kg | ||||

The machine can be customized according to your requirements. Such as PCB size, Length, Width, Height, cooling fan, and Touch Screen. It also can be customized to your company Logo or Brand Name.

We accept OEM & ODM.

We accept OEM & ODM.

Packing Details: Plywood case, for export!

Port: Shenzhen

Delivery Details: About 10-15 working days.

Port: Shenzhen

Delivery Details: About 10-15 working days.

Our Company

Welcome to Shenzhen Censtar Technology Co., Ltd., your premier source for high-quality SMT & DIP PCB assembly line machines. With a specialized engineering team dedicated to designing and manufacturing our products. We have over 13 years of experience in designing and manufacturing SMT Assembly Machine, and PCB Handling Machine. We are experts in customized solutions for PCB Conveyor, PCB Loader, PCB Unloader, PCB Buffer, PCB reject conveyor, PCB inverter, PCB stacker, Wave Solder Infeed/Outfeed, Surface Cleaning Machines, PCB Shuttle Conveyor, Solder Paste Printers, Reflow Oven, Wave Soldering machine and much more. We provide Full SMT & DIP Production Line Solutions. Our machines are built to the highest standards, using the latest technology and materials to ensure their durability and long lifespan. Our knowledgeable and friendly staff is always on hand to provide the support and expertise you need to get the most out of your investment.

Our success is a result of our dedication to quality and customer satisfaction. We have served customers in 40 countries throughout Europe, America, the Middle East, Southeast Asia, Africa, etc. We help many customers establish factories in LED, TV, Phone, Router, EMS, and other industries all over the world and train over 450 experts and technicians. We are committed to being our customers' most reliable Chinese partner, providing them with the support they need to achieve their goals.

At Shenzhen Censtar Technology Co., Ltd., we take pride in our attention to detail and commitment to delivering reliable and high-performing products. We not only provide SMT & DIP Line equipment, but also provide technical support and services, Besides we give our customers more reasonable and professional suggestions. Our experienced team of engineers and technicians work tirelessly to ensure that every product is manufactured to the highest quality standards, and we provide comprehensive after-sales support to ensure that our customers are completely satisfied with their purchase.

Whether you are looking for customized solutions for your PCB assembly line or simply seeking advice and support, we are here to help. Contact us today to learn more about how we can help you achieve your goals and take your business to the next level!

Our success is a result of our dedication to quality and customer satisfaction. We have served customers in 40 countries throughout Europe, America, the Middle East, Southeast Asia, Africa, etc. We help many customers establish factories in LED, TV, Phone, Router, EMS, and other industries all over the world and train over 450 experts and technicians. We are committed to being our customers' most reliable Chinese partner, providing them with the support they need to achieve their goals.

At Shenzhen Censtar Technology Co., Ltd., we take pride in our attention to detail and commitment to delivering reliable and high-performing products. We not only provide SMT & DIP Line equipment, but also provide technical support and services, Besides we give our customers more reasonable and professional suggestions. Our experienced team of engineers and technicians work tirelessly to ensure that every product is manufactured to the highest quality standards, and we provide comprehensive after-sales support to ensure that our customers are completely satisfied with their purchase.

Whether you are looking for customized solutions for your PCB assembly line or simply seeking advice and support, we are here to help. Contact us today to learn more about how we can help you achieve your goals and take your business to the next level!

Q: What can we do for you?

A: We have more than 13 years of experience in designing and manufacturing SMT & DIP Assembly machines and PCB Handling Machines. PCB Conveyor, PCB Loader, PCB Unloader, PCB Buffer, Surface Cleaning Machines, PCB Shuttle Conveyor, Reflow Oven, Wave Soldering, Pick and Place, SPI, AOI and much more. We take pride in our ability to provide innovative solutions that meet the specific needs of our clients.

Q: Are you a trade company or manufacturer?

Q: What is your delivery date?

A: The delivery date is about 10-15 working days after receive the payment.

Q: What is your payment terms?

A: 30% deposit before production, 70% payment before shipment.

Q: What is the payment way?

A: We accept the payment terms: T/T, Western Union, etc.

Q: Is this machine easy to use? If I have no experience, can I operate it well?

A: Yes, Our machine is easy to use. Usually, you need 1 day to learn how to operate. If you are a technician, learning will be faster. If you still have questions, please contact us.

Q: Do you provide user manuals and operating videos to support us?

A: We will provide an English user manual for free, and provide an operation video. Our software is all in English.

Q: If we come to your factory, will you provide free training?

A: Yes, of course. You are warmly welcome to visit our factory and we will arrange free training for you.

Q: When we encounter problems during operation, what services can you provide?

A: We can invite our engineers to your company for guidance, but you are responsible for the engineer's round-trip flight tickets, food, and accommodation.

Q: How can we guarantee quality?

A: Strict QC before shipping the products, Always final Inspection before shipment.

Q: Why choose you?

A: We are the Leading SMT & DIP Machine Manufacturer in China. We provide you with high-quality materials at factory prices. OEM & ODM services offered, meet all your needs. We ensure One-Stop after-sales service.

Thank you for your time and consideration. We look forward to the possibility of establishing a successful business partnership with you.

A: We have more than 13 years of experience in designing and manufacturing SMT & DIP Assembly machines and PCB Handling Machines. PCB Conveyor, PCB Loader, PCB Unloader, PCB Buffer, Surface Cleaning Machines, PCB Shuttle Conveyor, Reflow Oven, Wave Soldering, Pick and Place, SPI, AOI and much more. We take pride in our ability to provide innovative solutions that meet the specific needs of our clients.

Q: Are you a trade company or manufacturer?

A: We are a manufacturing company, located in Shenzhen, China. Full SMT & DIP machines manufacturer; OEM & ODM service are available.

Q: What is your delivery date?

A: The delivery date is about 10-15 working days after receive the payment.

Q: What is your payment terms?

A: 30% deposit before production, 70% payment before shipment.

Q: What is the payment way?

A: We accept the payment terms: T/T, Western Union, etc.

Q: Is this machine easy to use? If I have no experience, can I operate it well?

A: Yes, Our machine is easy to use. Usually, you need 1 day to learn how to operate. If you are a technician, learning will be faster. If you still have questions, please contact us.

Q: Do you provide user manuals and operating videos to support us?

A: We will provide an English user manual for free, and provide an operation video. Our software is all in English.

Q: If we come to your factory, will you provide free training?

A: Yes, of course. You are warmly welcome to visit our factory and we will arrange free training for you.

Q: When we encounter problems during operation, what services can you provide?

A: We can invite our engineers to your company for guidance, but you are responsible for the engineer's round-trip flight tickets, food, and accommodation.

Q: How can we guarantee quality?

A: Strict QC before shipping the products, Always final Inspection before shipment.

Q: Why choose you?

A: We are the Leading SMT & DIP Machine Manufacturer in China. We provide you with high-quality materials at factory prices. OEM & ODM services offered, meet all your needs. We ensure One-Stop after-sales service.

Thank you for your time and consideration. We look forward to the possibility of establishing a successful business partnership with you.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices