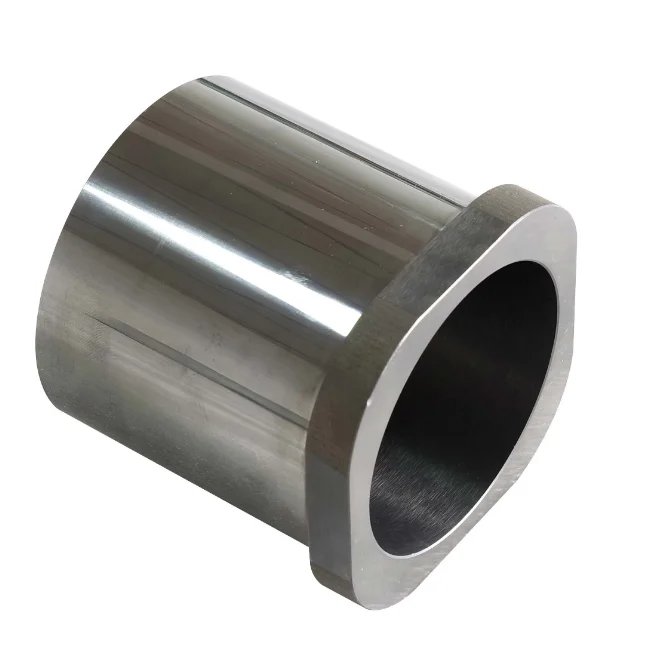

Shaft Sleeve Plain Cylindrical bushing Pump Du Bushing Submersible Slurry Pump Bushing

- Category: >>>

- Supplier: Zhuzhou Sunrise Hardmetal Tools Co. Limited

Share on (1601199507260):

Product Overview

Description

Products Description

Tungsten carbide shaft sleeve

Product features and applications:

It's widely used in petrochemical industries and other industries which call for high properties of the bearing bushings or

shaft sleeves.Tungsten carbide BEARING is the basic material among the frictional materials. They are widely use as the basic components forsealing. And the bushings are widely adopted in petrochemical industry due to its excellent performances such as wear ability,anti corrosion etc.

It's widely used in petrochemical industries and other industries which call for high properties of the bearing bushings or

shaft sleeves.Tungsten carbide BEARING is the basic material among the frictional materials. They are widely use as the basic components forsealing. And the bushings are widely adopted in petrochemical industry due to its excellent performances such as wear ability,anti corrosion etc.

Product Paramenters

Grade No | Co% | Density(g/cm3) | Hardness(HRA) | TRS(>N/mm2) |

SR11-C | 9-11 | 14.33-15.53 | 88.6-90.2 | 2800 |

SR15-C | 15.5-16 | 13.84-14.04 | 85.6-87.2 | 2800 |

SR15X | 14.7-15.3 | 13.85-14.15 | >89 | 3000 |

SR20 | 18.7-19.1 | 13.55-13.75 | >83.9 | 2800 |

SR06X | 5.5-6.5 | 14.8-15.05 | 91.5-93.5 | 2800 |

SR08 | 7.5-8.5 | 14.65-14.85 | >89.5 | 2500 |

SR09 | 8.5-9.5 | 14.5-14.7 | >89 | 2800 |

SR10X | 9.5-10.5 | 14.3-14.6 | 90.5-92.5 | 3000 |

Details Images

Our Advantages

1. Increased Bearing Life

Our exclusive cladding sustains tight tolerances and remains durable, even under extreme heat and stress.

2. Reduced Operational Costs

3. Improved Mud Motor Performance

Our exclusive cladding sustains tight tolerances and remains durable, even under extreme heat and stress.

2. Reduced Operational Costs

3. Improved Mud Motor Performance

Operators can push motors without damaging the bearings, permitting sharper turns, faster penetration and less drilling time.

4. Enhanced Drilling Accuracy

Reduced bearing wear means that design tolerances are maintained downhole, resulting in improved mud motor control and greater

drilling accuracy.

5. Unsurpassed Quality Standards

Our radial bearings are designed and manufactured according to stringent quality standards that govern material selection,

machining, infiltration brazing, surface finishing and packaging.

Specialty precision machining Manufacturer

1.Surface treatment:Zn-plating,Ni-plating,Cr-plating,Black oxide,Sand blasting,anodzing, Hot-dip galvanizing, color zinc plating,

powder coating, chemical oxidation, painting, electroplating, rust prevention

2.Machining equipment:CNC machining center, grinding machine, milling machine, drilling machine,horizontal milling machine,

chamfering machine, Metal Stamping ,CNC cutting machine etc.

4. Enhanced Drilling Accuracy

Reduced bearing wear means that design tolerances are maintained downhole, resulting in improved mud motor control and greater

drilling accuracy.

5. Unsurpassed Quality Standards

Our radial bearings are designed and manufactured according to stringent quality standards that govern material selection,

machining, infiltration brazing, surface finishing and packaging.

Specialty precision machining Manufacturer

1.Surface treatment:Zn-plating,Ni-plating,Cr-plating,Black oxide,Sand blasting,anodzing, Hot-dip galvanizing, color zinc plating,

powder coating, chemical oxidation, painting, electroplating, rust prevention

2.Machining equipment:CNC machining center, grinding machine, milling machine, drilling machine,horizontal milling machine,

chamfering machine, Metal Stamping ,CNC cutting machine etc.

Company Profile

Zhuzhou Sunrise Hardmetal Tools Co., Limited is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grindingand dispersion process. All our products were

best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices