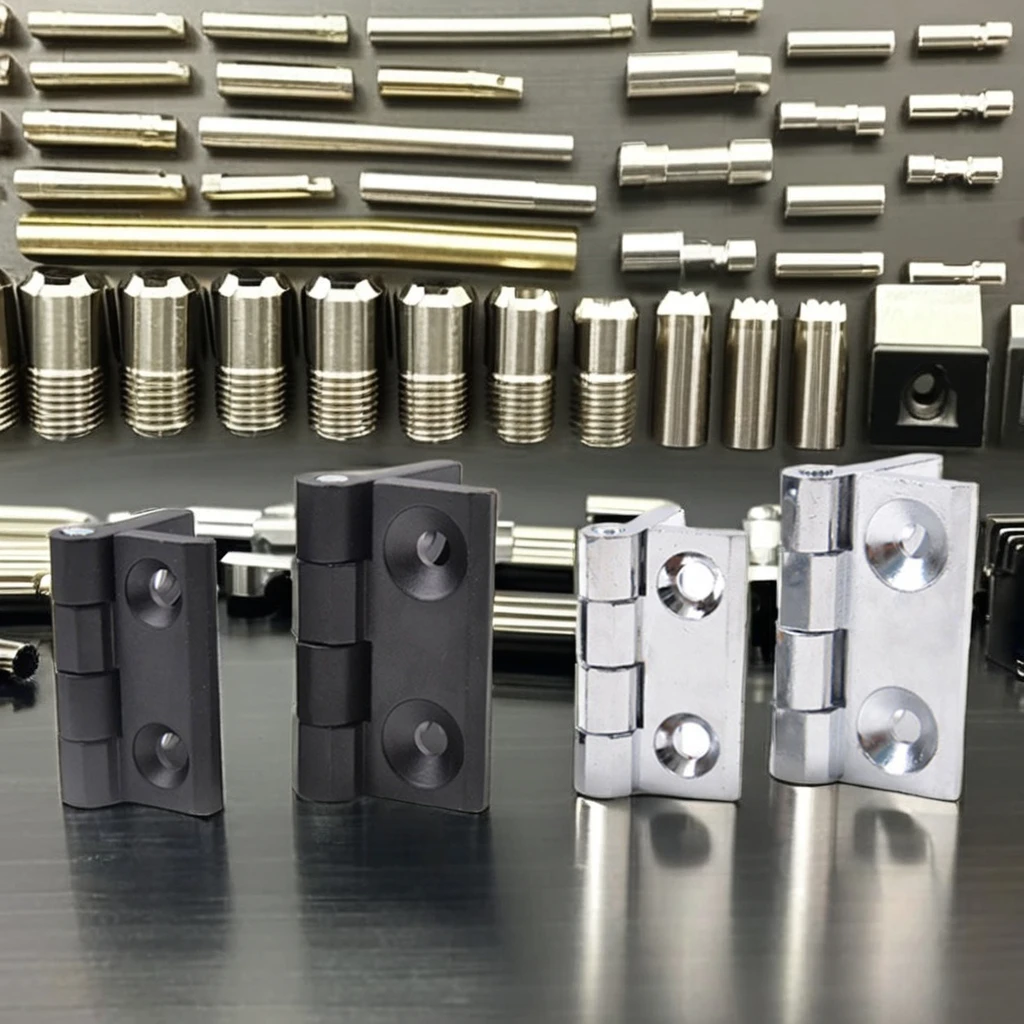

High Quality Investment Casting Hinges for Electrical Cabinets Zinc Die Casting Service

- Category: >>>

- Supplier: Dongguan Xiangyu Metal Products Co. Ltd.Dongguan Ltd.

Share on (1601200526645):

Product Overview

Description

Overview

Product Name | Zinc Aluminum Alloy Hardware Electrical Cabine |

Material | Zinc Alloy |

Process | Casting +Machining(if Need)+surface Treatment |

Drawing Format | JPEG, PDF, IGS, STEP, DWG...etc |

Packing | Plywood Pallet, Plywood Box Or Customize As Customer's Requirement |

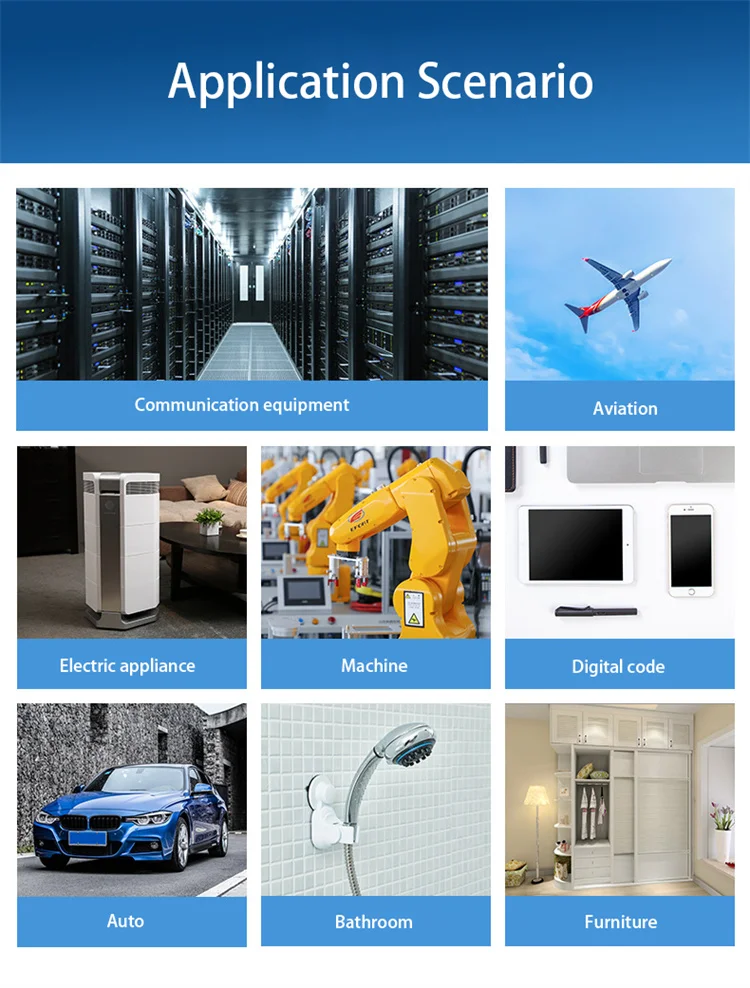

We now have 300 customers from all over the world.

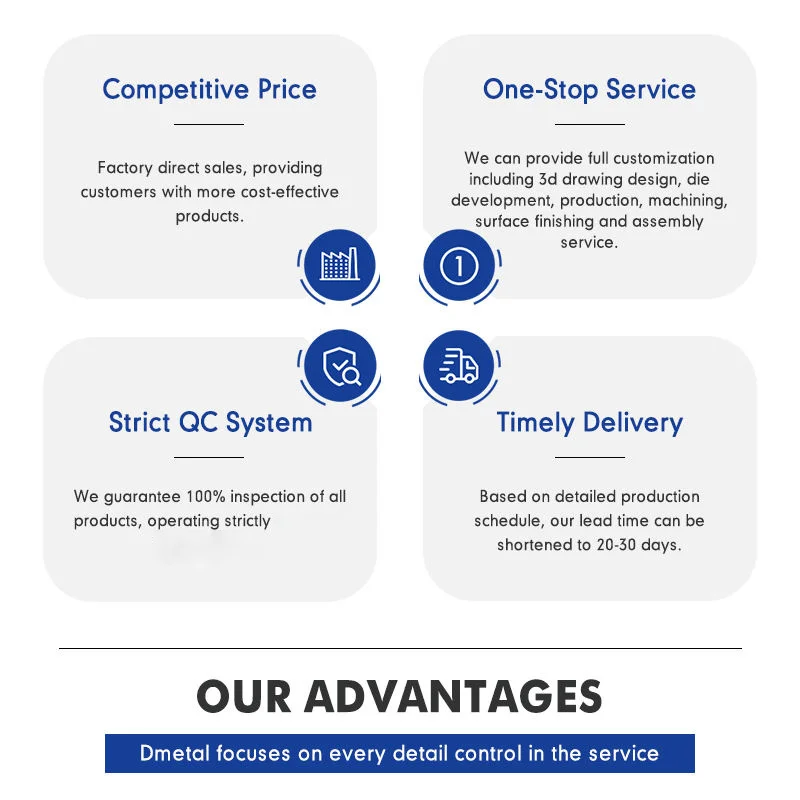

1. We have own factory and 80% of staff in our company worked for more than 15 years.

2. We provide a competitive price and high quality.

3. High precision, tolerance can be within ±0.01mm.

4. 22 years' export experience.

5. Small order also is welcomed.

6. We provide one-stop service, including mold and assembly.

7. All your information is confidential, and we can sign NDA as well.

FAQ

Q1. Are you a factory or trade company?

We are a factory located in No.8 Huaqiang Road, Chang'an Shangsha Sixth Industrial Zone, Dongguan City, Guangdong Province, China

Welcome to visit our factory.

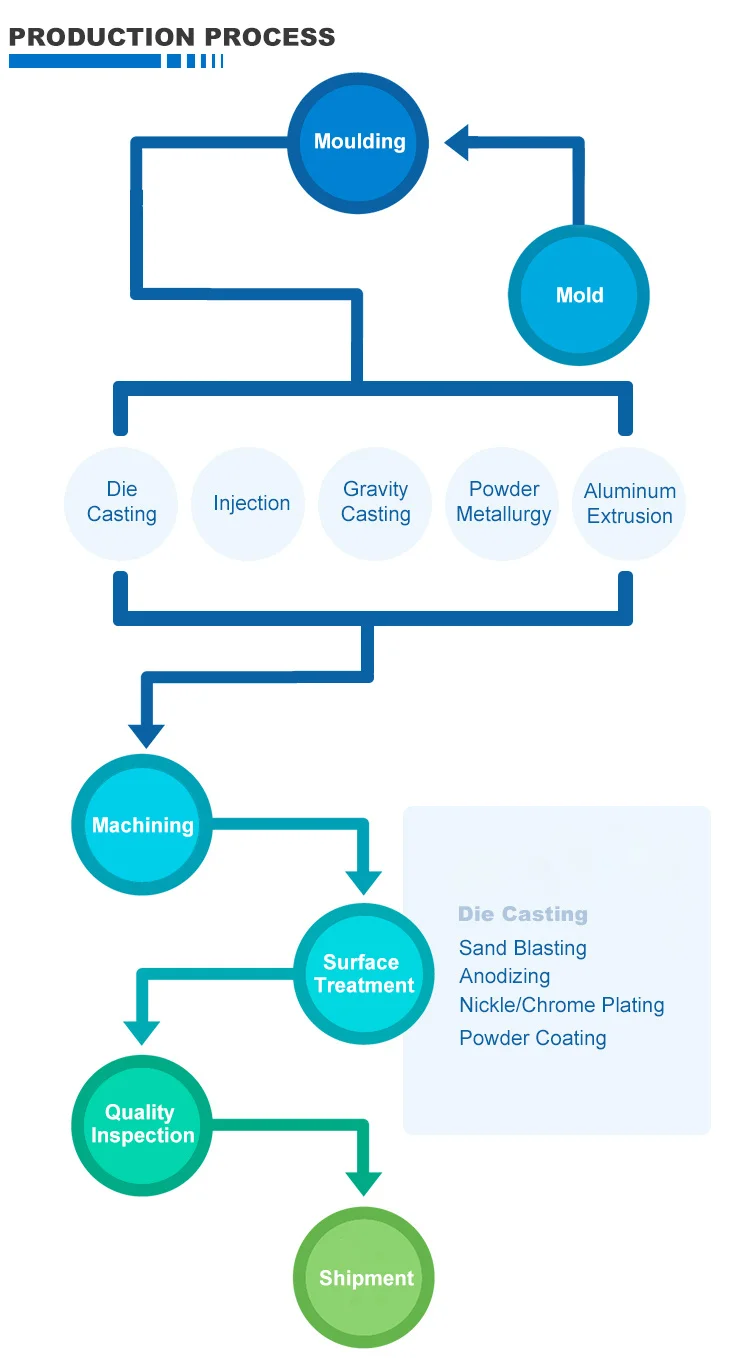

Q2. What kind of production service do you provide?

Mold making, die casting, CNC machining, stamping, assembly, and surface treatment.

Q3. How about the lead time?

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality?

♦We have got IATF16949 certificate.

♦We will make the operation instruction once the sample is approved.

♦We will 100% inspect the products before shipment.

♦Transactions can be through Alibaba's trade assurance.

Q5. How long should we take for a quotation?

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 24hours-2 days.

Q6. What is your quotation element?

Drawings or Sample, Material, Finish, and Quantity.

Q7. What is your payment term?

Mold: 30-50% prepaid, balance after sample approval.

Goods: 30-50% prepaid, balance T/T before shipment.

Q8:Do you accept customized orders?

A: Yes. With design team, OEM and ODM orders are highly welcome.

Q9:Can you accept mould making?

A: Yes.

1.Durable aluminum construction: This Microcamera Housing is made from high-quality aluminum, providing a robust and long-lasting solution for your electronics needs. The product is designed with a robust casting and machining process, ensuring that it can withstand wear and tear over time.

2.Customizable dimensions: The housing is available in customized sizes, allowing you to choose the perfect dimensions to fit your specific camera or electronics application. This flexibility ensures that the housing perfectly aligns with your requirements, providing optimal protection and performance.

3.Anodized surface treatment: The Microcamera Housing features an anodized surface treatment, which not only enhances the product's durability but also ensures resistance to corrosion and oxidation. This advanced surface treatment adds an extra layer of protection to your camera or electronics, prolonging its lifespan.

4.Comprehensive quality control: 100% inspection is carried out to ensure the highest quality standards are met. This rigorous quality control process guarantees that every Microcamera Housing is free from defects, providing you with a reliable and dependable product.

5.OEM and ODM services: The Microcamera Housing is available with OEM and ODM customization options, enabling you to tailor the product to your specific branding and design needs. This flexibility allows you to create a housing that perfectly aligns with your unique business requirements and stands out from the competition.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices