Factory Any Size Copper Foil Anti bacterial Tape And EMI Shielding Tape Copper Foil Adhesive Tape

- Category: >>>

- Supplier: Shenzhen Xinst Technology Co. Ltd.Shenzhen Ltd.

Share on (1601201062350):

Product Overview

Description

Products Description

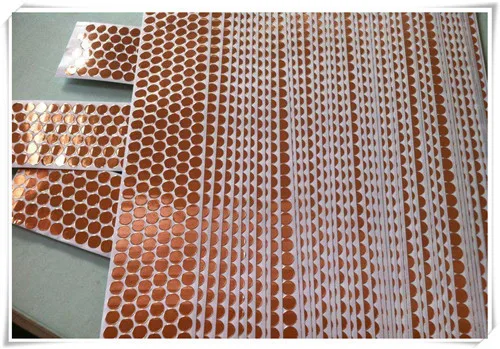

Factory Any Size Copper Foil Anti-bacterial Tape And EMI Shielding Tape Copper Foil Adhesive Tape

Copper Foil Tape 0702-60-22 has a 22um smooth copper(Purity is 99.95%) foil backing with a 35um acrylic pressure-sensitive adhesive and liner.

The un-plated copper with adhesive is a common EMI shielding tape for non-corrosive conditions.

Material :Copper Film

Adhesive:Acrylic adhesive

Width:380mm/OEM

Length:50M/OEM

Temperature resistance: 120℃

Plastic Core:76mm Diameter

*Excellent shielding effectiveness

*Anti-static

*Heat-resistant

*Waterproof

*Solvent resistance

*Easy to die cut complex shape

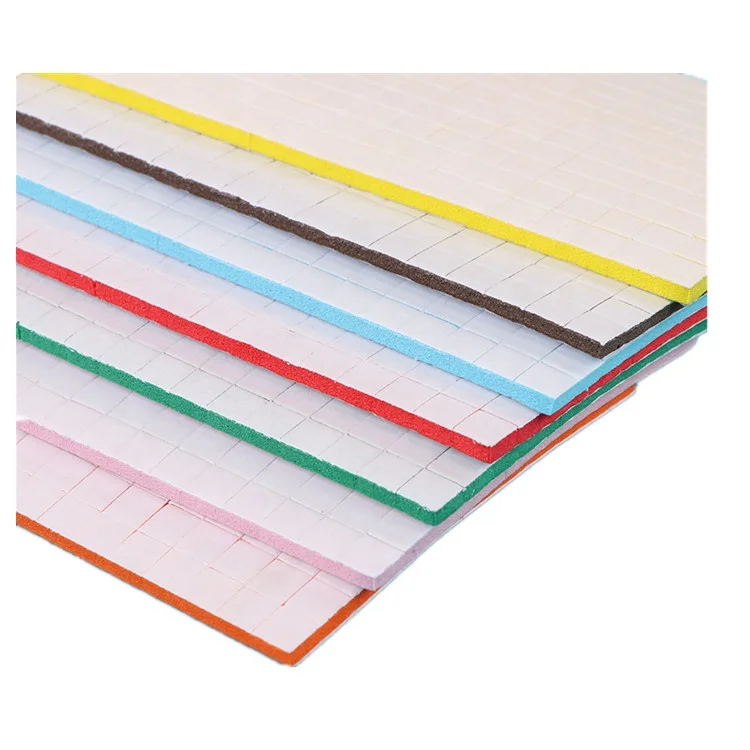

Different Types Copper Film Tape

Specification

Product Code | Xinst0701 | Xinst0702 | Xinst0703 |

Name | Single Sided Copper Foil Tape | Double Sided Copper Foil Tape | Mylar Copper Foil Tape |

Thickness | 0.05mm-0.09mm | 0.05mm-0.12mm | 0.085mm-0.15 |

Adhesive | Acrylic/Conductive Acrylic | Acrylic/Conductive Acrylic | Acrylic |

Backing | Copper Foil | Copper Foil | Copper Foil |

Short-temperature | 180 | 180 | 180 |

Long-temperature | 120 | 120 | 120 |

-We provide OEM production to meet any of your requirement

-Die cutting any shape for you

-Free samples available

Features:

1)Dead soft copper foil backing for good shielding effectiveness, soldering and converting (slitting and die cutting).

2)Conductive particles in the adhesive on both sides provides low contact resistance between substrates and the backing to drain static charge.

2)Conductive particles in the adhesive on both sides provides low contact resistance between substrates and the backing to drain static charge.

3)Conductive Acrylic pressure-sensitive adhesive has good resistance to heat, oxidation, solvents and oils.

4)Removable liner on both sides makes it easy to handle and die cut complex shapes.

4)Removable liner on both sides makes it easy to handle and die cut complex shapes.

Application

1)Commonly used for RFI/EMI (radio-frequency interference or electromagnetic interference) shielding and ESD (electrostatic discharge) grounding for components, integrated circuits, connectors, cables, motors, equipment enclosures/cabinets and shielded rooms.

2)Conductive circuit or bus bar for low voltage applications

3)Used in jobs requiring high conductivity or shielding effectiveness for a given thickness.

4)Best used in non-corrosive environments.

5) For Soldering,EMI Shielding Barrier,Stained Glass

Company Profie

FAQ

1)How to order from xinst?

Just send us email or call us.

2)Do you offer the free sample for testing?

Yes, we offer the sample free, but you courier charges.

3)How to ship the order?

We will suggest you the appropriate way of shipment, by sea, by air or by courier. Of course if you will have your own forwarder, that is no problem.

4)Can we trust the quality of product from Xinst? Sure, do not worry about that. Our quality wills absolutely compliance to the sample we send. If not, we will take charge of that.

5)What payment Xinst accepts?

For the small quantity, we request 100% advanced TT payment; other conditions, negotiable. Sorry, we did not accept the Credit card for the time being.

6)How about the lead time of per order?

If the tape you order have stock, we can ship out within 1~3 days. If there is no stock, you need to wait about 5~12 days. If you are request the die-cuts, the time shall longer.

Friendly Tips:

If you find our tapes interested, please send your detailed requirements to us. Xinst’s team would offer different solutions to you within 12 hours. Free samples are also available.

Just send us email or call us.

2)Do you offer the free sample for testing?

Yes, we offer the sample free, but you courier charges.

3)How to ship the order?

We will suggest you the appropriate way of shipment, by sea, by air or by courier. Of course if you will have your own forwarder, that is no problem.

4)Can we trust the quality of product from Xinst? Sure, do not worry about that. Our quality wills absolutely compliance to the sample we send. If not, we will take charge of that.

5)What payment Xinst accepts?

For the small quantity, we request 100% advanced TT payment; other conditions, negotiable. Sorry, we did not accept the Credit card for the time being.

6)How about the lead time of per order?

If the tape you order have stock, we can ship out within 1~3 days. If there is no stock, you need to wait about 5~12 days. If you are request the die-cuts, the time shall longer.

Friendly Tips:

If you find our tapes interested, please send your detailed requirements to us. Xinst’s team would offer different solutions to you within 12 hours. Free samples are also available.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices