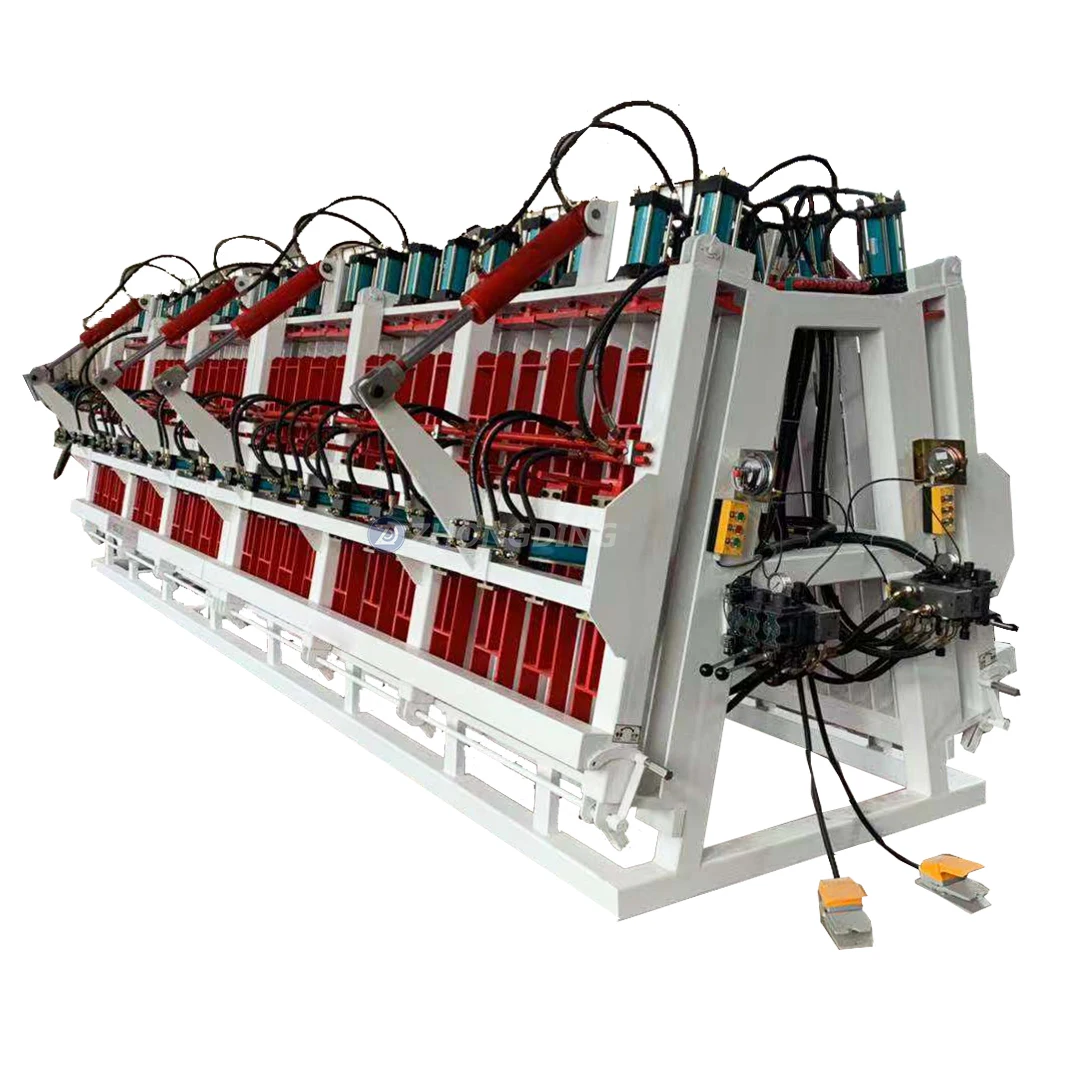

Hydraulic Woodworking glulam timber Beam Wood Board Laminated Press Rotary Composer Clamp Carrier Machine

- Category: >>>

- Supplier: Qingdao Zhongding Machinery Co. Ltd.

Share on (1601202146429):

Product Overview

Description

Hydraulic Woodworking Wood Beam Wood Board Laminated Press Rotary Composer Clamp Carrier Machine glulam press

Hydraulic composer is also called edge glued panel press, clamp carrier or solid wood laminating press.

It can be used to laminate kinds of dimension of solid wood panel.

1. 3D software design to make sure machine structure reasonable.

2. Heavy duty structure design---High density braced sheetings as back worktop and pressure from the above and front can prevent the curved angle and make the board glued completely. Help customer save material and costs. (Less sanding and more output).

3. Free adjustment of pressure can meet different length and thickness panel making. Continuous pressure are ensured by pressure-supplement system to guarantee the panel quality and stablity.

It can be used to laminate kinds of dimension of solid wood panel.

1. 3D software design to make sure machine structure reasonable.

2. Heavy duty structure design---High density braced sheetings as back worktop and pressure from the above and front can prevent the curved angle and make the board glued completely. Help customer save material and costs. (Less sanding and more output).

3. Free adjustment of pressure can meet different length and thickness panel making. Continuous pressure are ensured by pressure-supplement system to guarantee the panel quality and stablity.

Wood Based Panels Machinery Woodworking Wood press Pneumatic Control Rotary Wood Composer Wood Clamp Carrier | ||||||||

Model | MH1325-2 | MH1346-2 | MH1352-2 | MH1362-2 | ||||

Max.processing length | 2500mm | 4600mm | 5200mm | 6200mm | ||||

Max.processing width | 1300mm(Customized) | 1300mm | 1300mm | 1300mm | ||||

Max.Processing thickness | 10~150mm(Customized) | |||||||

Top cylinders dia | 80mm | |||||||

Top cylinders quantity | 6pcs | 12pcs | 14pcs | 16pcs | ||||

Side Top cylinder dia | ||||||||

Side cylindes quantity | 6pcs | 12pcs | 14pcs | 16pcs | ||||

Lift cylinder dia | 63mm | |||||||

Lift cylinder quantity | 2pcs | |||||||

Hydraulic power | 5.5kw | |||||||

Hydraulic pressure | 16Mpa | 16Mpa | ||||||

Installation Size | 3100x2300x2320mm | 5000*2320*3320mm | 5600*2320*3320mm | 6600*2320*3320mm | ||||

Weight | 3800kg | 6800kg | 7200kg | 8000kg | ||||

Thickened body

The body is made of high-quality steel trough material, and the whole body is thickened. The thickened body can make the machine stable during use and extend its service life.

Stable operation

This machine adopts the hydraulic principle and has the characteristics of stable movement speed, high pressure, and even pressure.

Smooth material output

Apply pressure on the top and front of the workpiece to avoid tilting and make the glued panels smooth.

Flexible equipment

The front presser foot can be moved left and right as a whole according to the specifications of the workpiece.

Sectional Type

segmented structure

The segmented structure is more flexible and efficient when processing short materials.Wood of different sizes can be processed separately at multiple workstations, which greatly improves the efficiency of processing short materials.

Double sided Type

The A-shaped design makes full use of the space. Work can be performed on both sides of the machine at the same time, which can greatly improve efficiency.

Four sided rotary Type

The machine has four processing positions, which are switched by fully automatic rotation.Simultaneous multi-layer assembly, wide processing range and high efficiency.The four working surfaces are cycled, four-sided imposition can be completed continuously.

12m gantry downturn type for glulam beam timber

The Vertical Type downward open structure is convenient for loading and unloading of larger and longer workpieces.Mainly used for processing extra-long glulam beams.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices