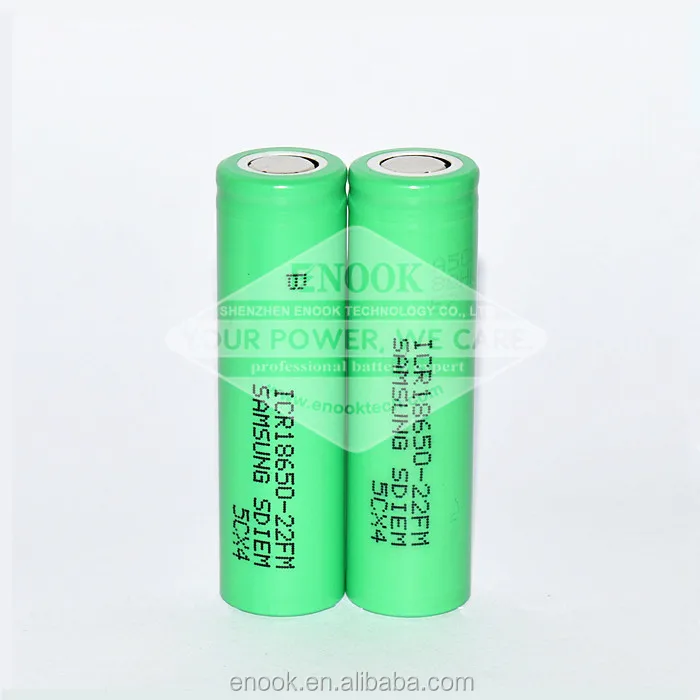

Excellent quality 18650 battery 1500mah 3.7v high popularity and colorful 3c battery 18650 2200 mah

- Category: >>>

- Supplier: Xiamen New Journey Technology Co. Ltd.

Share on (1601202348667):

Product Overview

Description

Products Description

Max recommended charge and discharge cell body temperature | Charge:0~ 60℃ Discharge::—20~ 60℃ |

Maximum short term allowable charge and discharge cell body temperature Charging and discharging at these conditions will shorten cell cycle life. | Charge:60℃ Discharge:75℃ |

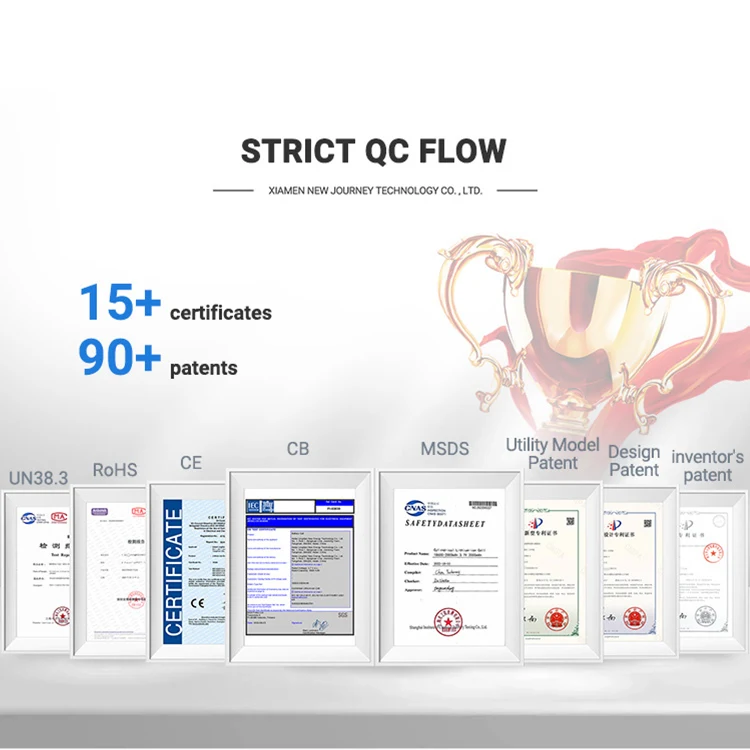

Certification | CE/CB/RoHS/UN38.3/MSDS/ISO 9001/PSE/FCC |

Our Cells' Testing Report

e.g. MODEL:18650 2500mAh (Contact us to get your expect model testing report) | ||||||||

Ⅰ. Electronic Performance | ||||||||

NO. | ITEM | Standard | TESTING METHOD | |||||

1 | Discharge rate capability (Room temperature) | The charging and discharge cures must be smooth | Charge as described in 2.2, rest for 10min; and discharge with different constant currents and cut off at 2 75V | |||||

0.2C | ≥100% | |||||||

0.5C | ≥99% | |||||||

1C | ≥95% | |||||||

2C | ≥95% | |||||||

3C | ≥95% | |||||||

5C | ≥93% | |||||||

2 | Cycle life | 500 Cycles | Each cycle is an interval between the charge (charge current 0.5C) at 25+3℃, rest 10minutes, and discharge (discharge current 3C) with 2.75V cut-off, then rest 10 minutes. After 500 cycles, Capacity Retention =Cap(500th)/Cap(Av10)≥80% | |||||

3 | High-Low temperature discharge performance | -20℃ | ≥70% | Charge as described in 2.2, discharge to2.75V with current of 0.2C, and record the initial capacity. Charge as described in 2.2 rest for 2h in the environment with -20℃、25℃、55℃ (Rest for 4h at -20℃),and Charge as described in 2.2, discharge to2.75V with current of 0.2C, and record the initial capacity. Charge as described in 2.2rest for 2h in the environment with -20℃C、25℃、55℃(Rest for 4h at -20℃),and discharge to 2.75V with the current of 0.2C (Discharge to 2.5V at -20℃). Calculate the ratio of above discharge capacities to the initial capacity | ||||

-10℃ | ≥80% | |||||||

0℃ | ≥80% | |||||||

25℃ | ≥100% | |||||||

55℃ | ≥95% | |||||||

4 | Normal Storage | Retention capacity ≥90%* initial capacity | Tested the initial condition and initial capacity of battery. Store at 25 ± 2 ℃ for 28 days after standard charged, tested the final condition of battery. Then discharge at 0.5C to the discharge cut-off voltage 2.75 V, tested the residual capacity of battery. 0.5C/0.5C tested the recovery capacity of battery. Charge/discharge cycle can be conducted for3 times before meeting the standards | |||||

Recover capacity ≥95%* initial capacity | ||||||||

5 | High temperature Storage test | Retention capacity≥85%* Nominal capacity | Tested the initial condition and initial capacity of battery. Store at 55+2℃ for 7 days after standard charged, tested the final condition of battery, then discharge at 0.5C to the discharge cut-offvoltage2.75 V, tested the residual capacity of battery. 0.5/ C0.5C tested capacity the recovery battery. Charge/discharge cycle can be conducted for 3 times before meeting the standards | |||||

Recover capacity≥90%*Nominal capacity | ||||||||

Ⅱ. Environmental characteristics | ||||||||

NO. | ITEM | Standard | TESTING METHOD | |||||

1 | Temperature cycle test | No leakage,fire,explosion | Standard charge. Put the battery into20+5℃ chamber: raising the chamber temperature to75+2'℃ for 6h ; reducing the chamber temperature to-40+2℃ for 6h; charge the temperature within 30 minutes; repeating the sequence for 10 cycles; | |||||

2 | Drop | No leakage, fire, explosion | After standard charge ,cells dropped from aheight of 1.5m to the cement floor | |||||

3 | Vibration | No leakage, fire, explosion | After standard charge , cells are fixed on vibration table and subjected to vibration cycling at the rate of 1 Hz per minute between 10 Hz to 55 Hz. The excursion of the vibration is 1.52mm. The test has to be carried out for 90 minutes at x,y,z axes individually | |||||

Ⅲ. Safety Characteristics | ||||||||

NO. | ITEM | Standard | TESTING METHOD | |||||

1 | Over discharge | No leakage, fire, explosion | A discharged cells are subjected to a reverse charge at 1C for 90 min. | |||||

2 | Overcharge | No fire, explosion | After standard charge, after standard charge, continue to charge with a constant current1C/10Vper a cell, holding 1h. | |||||

3 | Short-circuit | No fire, explosion | After standard charge, Cells are stored in temperature of 20±5℃ and 55+5℃, Then short-circuited by connecting the positive and negative terminals with a total external resistance of 80±20mΩ, remain for 24h or the case temperature declines by 20% of the maximum temperature rise. | |||||

4 | Crush | No fire, explosion | After standard charge, Placed the cell in two iron plane moulds , with the most strongly13+1KN pressure for the moment compression. Once the maximum force has been applied, or an abrupt voltage drop of one-third of the original voltage has been obtained, or 10% of deformation has occurred compared to the initial dimension, the force is released | |||||

5 | Low-pressure | No leakage, fire, explosion | After standard charge, Put cell into the low pressure box, adjust the air pressure in the test chamber is 11.6 KPa, temperature to room temperature, let stand for 6 h. | |||||

6 | Seawater soak | No leakage, fire, explosion | After standard charge, cells immersed in3.5% NaCl solution (mass fraction, simulation under the normal temperature water composition) simulation under the normal temperature water composition in 2h, The cell completely submerged in water | |||||

Company Profile

Production Process

Customization Process

Certifications

FAQ

Q1. What is the capacity and voltage range of your batteries?

A:Our batteries come in various capacities, batteries with different capacities or voltages can be customized as needed.

A:Our batteries come in various capacities, batteries with different capacities or voltages can be customized as needed.

Q2. What safety features do your batteries have?

A:Our batteries are equipped with multiple safety features, including overcharge protection, over-discharge protection,overcurrent protection, and short-circuit protection. Additionally, they meet safety standards.

A:Our batteries are equipped with multiple safety features, including overcharge protection, over-discharge protection,overcurrent protection, and short-circuit protection. Additionally, they meet safety standards.

Q3. Can the batteries be installed in various environments?

A:Yes, our batteries are designed to be installed in a wide range of environments. However, it's essential to adhere to the recommended temperature and operating conditions outlined in the user manual.

A:Yes, our batteries are designed to be installed in a wide range of environments. However, it's essential to adhere to the recommended temperature and operating conditions outlined in the user manual.

Q4: Are your batteries environmentally friendly?

A:Our batteries are designed with environmental sustainability in mind, They are recyclable, and we encourage customers to participate in battery recycling programs.

A:Our batteries are designed with environmental sustainability in mind, They are recyclable, and we encourage customers to participate in battery recycling programs.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices