Manual Brick Machine Platform Mould Vibration Brick Making Machine Bricks Counting Packing Machine

- Category: >>>

- Supplier: Henan Yugong Machinery Equipment Co. Ltd.

Share on (1601202966534):

Product Overview

Description

Product Description

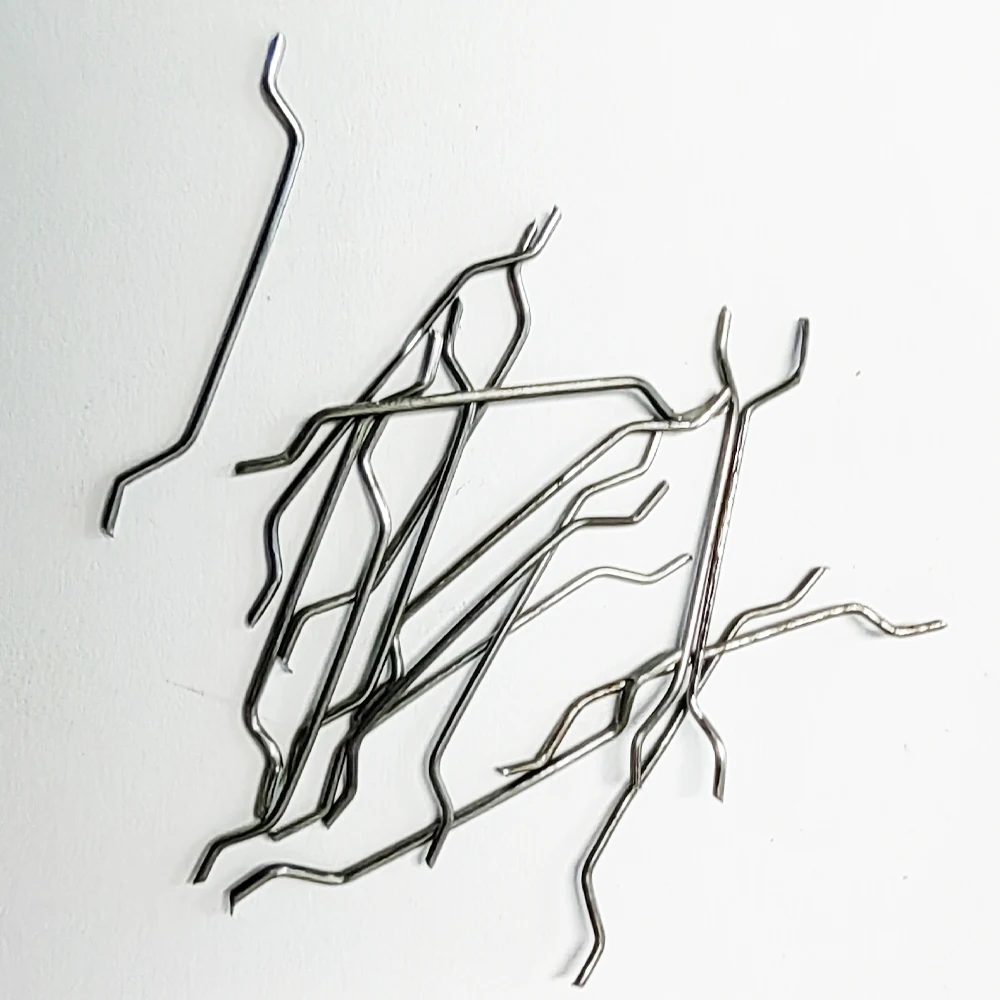

Brick Block Making Machine/Line, small scale cement concrete fly ash paver interlocking brick block making machine price is a small block production equipment, easy to operate, can produce hollow block, porous block, solid concrete brick, etc. There is a vibrator on the upper mold and two vibrators on the lower mold. The exciting force in three different directions makes the block quality good. This kind of manual block making machine uses spring to cushion and pressurize, which reduces wear. The product has the advantages of fast forming, high density and high pressure. After moulding, these blocks can bear the weight of one person

Specification

Type | Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC) |

Brick Raw Material | Cement |

Processing | Brick Production Line |

Production Capacity (Pieces/8 hours) | 4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours |

Voltage | 380V |

Dimension(L*W*H) | 2060*1730*2580mm |

Brick size | 400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm |

Warranty of core components | 1 Year |

Core Components | PLC, Pressure vessel, Engine, Gear, Motor, Pump, Bearing, Gearbox |

Weight (KG) | 2000kg |

Automatic Brick making machine

Brick making machine is the mechanical equipment for producing bricks, generally using stone powder, fly ash, slag, rubble, sand, water, etc. as raw materials. Without the firing process, it is more environmentally friendly and saves resources than vacuum brick machine.

The production process of brick making machine: crushing the quicklime with the jaw crusher - entering the pulverizer for grinding-mixing with other ingredients evenly - entering the digestion bin for digestion - entering the wheel mill for rolling - pressing and forming by hydraulic brick machine - entering autoclave for autoclave curing - drying for about ten days - finished product.

Packing & Delivery

Company Profile

FAQ

We Recommend

New Arrivals

New products from manufacturers at wholesale prices